In the world of machinery and engineering, tapered roller bearings play a crucial role. These components are designed to handle heavy loads while allowing smooth movement. John Smith, a leading expert in the bearing industry, emphasizes, "Tapered Roller Bearings are vital for efficient machine operation."

When selecting the best tapered roller bearing, various factors come into play. Quality, load capacity, and durability are fundamental aspects. However, many buyers overlook these vital details. This negligence can lead to poor performance and increased maintenance costs.

Manufacturers often face challenges in producing consistently high-quality tapered roller bearings. The market is filled with options, but not all comply with industry standards. It’s essential to carefully evaluate each choice. The right bearing can enhance productivity and reduce downtime. In this review and buying guide, we aim to simplify your decision-making process in this complex landscape.

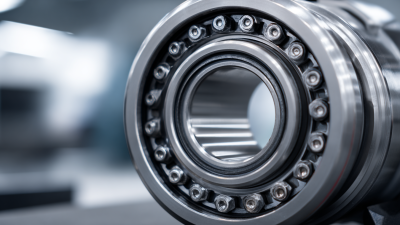

Tapered roller bearings are essential components in various machinery and automotive applications. They consist of rolling elements shaped like truncated cones. This design allows them to handle radial and axial loads simultaneously. According to a report by the International Journal of Engineering and Technology, tapered roller bearings have a higher load-carrying capacity compared to other bearing types.

The functionality of these bearings is rooted in their geometry. Their tapered shape promotes better alignment and load distribution. Data from the World Bearing Association indicates that these bearings are widely used in heavy-duty applications, including trucks and construction equipment. Their efficiency varies depending on the design and materials used. However, even the best products can encounter issues like wear and incorrect installation. It's crucial to consider these factors to ensure optimal performance.

While the demand for tapered roller bearings is on the rise, users often overlook maintenance. Regular inspections can prevent premature failure. Industry reports show that over 30% of bearing failures are due to improper use. This highlights the need for proper training and awareness among operators. Understanding the basics of tapered roller bearings is key to maximizing their lifespan and functionality.

| Model | Load Capacity (lbs) | Inner Diameter (inches) | Outer Diameter (inches) | Price ($) |

|---|---|---|---|---|

| Model A | 3000 | 2.5 | 4.5 | 45.99 |

| Model B | 3500 | 3.0 | 5.0 | 55.99 |

| Model C | 4000 | 3.5 | 6.0 | 65.99 |

| Model D | 2500 | 2.0 | 4.0 | 35.99 |

| Model E | 2800 | 2.8 | 4.8 | 40.00 |

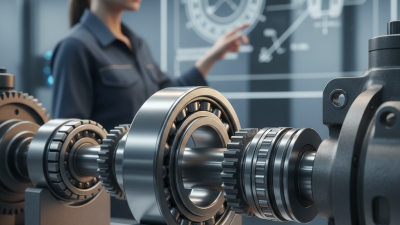

When selecting tapered roller bearings, there are key features to consider. The load capacity is crucial. This determines how much weight the bearing can support. Pay attention to the axial and radial load ratings. Without proper load ratings, your application may fail.

Another important aspect is the material construction. Most bearings are made from steel or ceramic. Steel is robust and popular for many applications. However, it may corrode in harsh environments. Ceramic offers excellent resistance but can be expensive. Think about your specific operational conditions.

Internal geometry is often overlooked but vital. This affects the bearing's performance and lifespan. A poorly designed internal structure can lead to premature wear. Ensure you understand the design specifications before making a choice. Balancing these features is not always easy. Sometimes compromise is necessary. Reflect on the priorities of your application to make the best choice.

This chart represents the average ratings of various key features to consider when selecting tapered roller bearings in 2026. The features include material quality, durability, load capacity, temperature resistance, and cost effectiveness.

Tapered roller bearings are essential in various industries. These bearings support heavy loads and provide stability. In 2026, the market for these products is projected to grow significantly, driven by demand from automotive and manufacturing sectors. Industry reports indicate a robust growth rate of 7% annually.

When looking for top models, it’s crucial to consider their load-carrying capacity and speed ratings. High-quality options can enhance machinery performance. However, not all bearings meet these standards. Some may fail prematurely under certain conditions. Users should evaluate these aspects carefully. Research shows that proper maintenance can extend bearing life by up to 30%.

In terms of brands, the variety can be overwhelming. Users often find it hard to choose the right type. A mix of cost, quality, and performance complicates the decision further. Many fall into the trap of opting for cheaper products. This can lead to increased downtime and maintenance costs. Prioritizing quality over price is a common yet crucial reflection point for buyers.

When it comes to tapered roller bearings, selection is key. These bearings are crucial for reducing friction and enhancing machine performance. According to a recent industry report, the global tapered roller bearing market is projected to reach $12.5 billion by 2026. This indicates strong demand across various sectors, especially in automotive and industrial machinery.

A comparative review of the best tapered roller bearings highlights several factors to consider. Load capacity is vital; high-quality bearings generally offer superior strength and durability. Additionally, the material used in manufacturing significantly influences performance. Steel is common, but advanced composites are becoming increasingly important for lightweight designs.

Despite their advantages, some tapered roller bearings have been found lacking in heat resistance. This can lead to premature failure, especially in high-load applications. Another common issue is improper installation, which can degrade performance over time. It's essential to engage in thorough research and evaluation before making a purchase. Understanding these factors ensures a better choice in the long run.

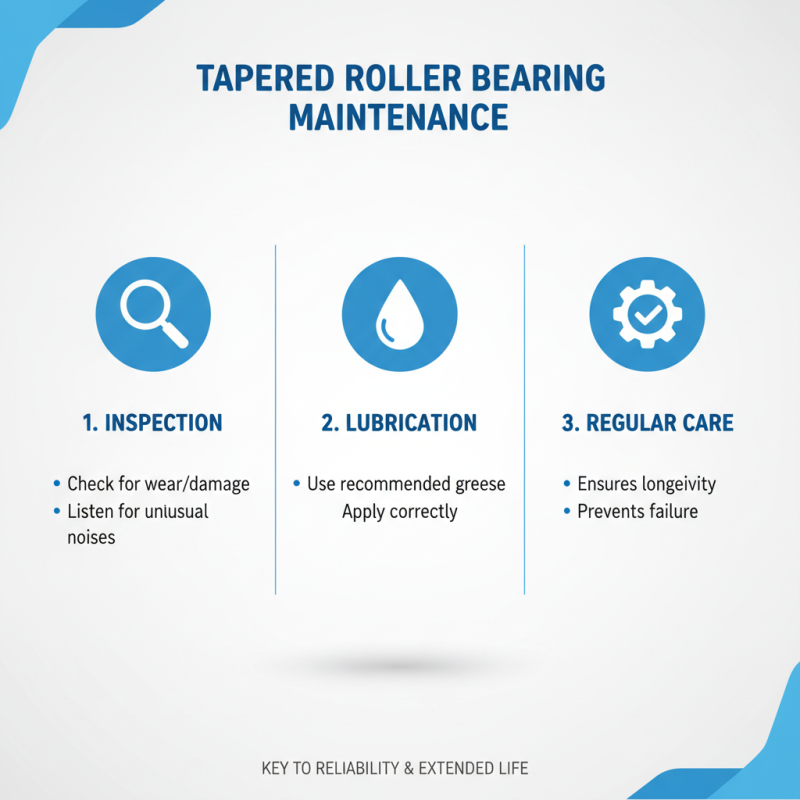

Proper maintenance of tapered roller bearings is essential for their longevity. Regular inspection is key. Check for signs of wear or damage. Look for unusual noises during operation. These can indicate that something isn’t right. Lubrication is crucial, too. Use the recommended grease and ensure it is applied correctly.

Overheating can damage bearings. Monitor the operating temperature. If it rises above normal, take action. It may be time to replace the lubricant or inspect alignment. Dust and contaminants can harm the bearing surfaces. Keeping them clean helps reduce wear. Incorporate dust shields or covers, if possible.

However, even with the best practices, mistakes can happen. Over-lubricating can lead to excess heat. Not all bearings are made equal. Some may need more frequent inspection. Reflect on your maintenance routine regularly. Are you missing anything? Adjust your approach as needed. Small changes can yield significant benefits over time.