Understanding the intricacies of U Groove Roller Bearings can be daunting. As an essential component in many industrial applications, selecting the right one is crucial. John Smith, a renowned expert in bearing technology, emphasizes, “Choosing a quality U Groove Roller Bearing can extend equipment life significantly.”

In this guide, you'll find insights and tips to help you make informed choices. U Groove Roller Bearings are designed for specific functions. They support smooth movement in various machinery. This specialized design can sometimes lead to confusion. The market offers many options, and not all of them meet industry standards.

Awareness of the specifications is vital. You must consider load capacity, material, and size before purchasing. Many overlook these factors, leading to premature failures. This guide aims to prevent such costly mistakes. A well-chosen U Groove Roller Bearing can enhance performance and durability. A little time spent on research today can save you headaches tomorrow.

U Groove roller bearings play a critical role in various applications, especially in systems requiring smooth, linear motion. These bearings have a unique groove shape, which allows for effective load distribution and minimizes friction. Commonly used in conveyor systems, sliding doors, and machinery, they provide reliable performance under different conditions.

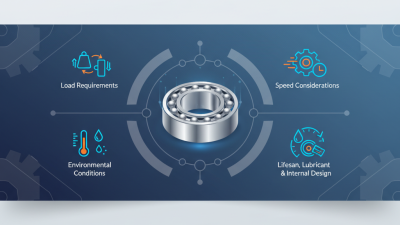

When choosing U Groove roller bearings, consider the load capacity and environmental factors. The material of the rollers should withstand wear and corrosion. Also, ensure compatibility with your specific application, as size can significantly affect performance.

Tips: Always check the manufacturer's specifications before making a purchase. Misjudging size can lead to malfunction. If you are unsure, consult with technical experts—they can provide valuable insights. Additionally, don’t forget to assess lubrication needs. Proper lubrication can enhance the bearing's lifespan. Pay attention to maintenance schedules to avoid premature failure.

When purchasing U groove roller bearings, it’s essential to consider several key factors. Start with size. Ensure the bearing fits your machinery perfectly. Measure the dimensions accurately before making a decision. A small error can lead to significant issues down the line.

Another vital aspect is load capacity. Identify the weight and type of load the bearing will handle. You need bearings that can support the required load without excessive wear. Ignoring this might result in early failure and costly replacements.

**Tips:** Don’t forget about material quality. Select bearings made from durable materials that resist corrosion and wear. Also, think about lubrication. Proper maintenance extends the bearing’s lifespan. Understand potential environmental conditions that may impact performance. Research thoroughly to avoid common pitfalls. You might overlook something crucial if not careful.

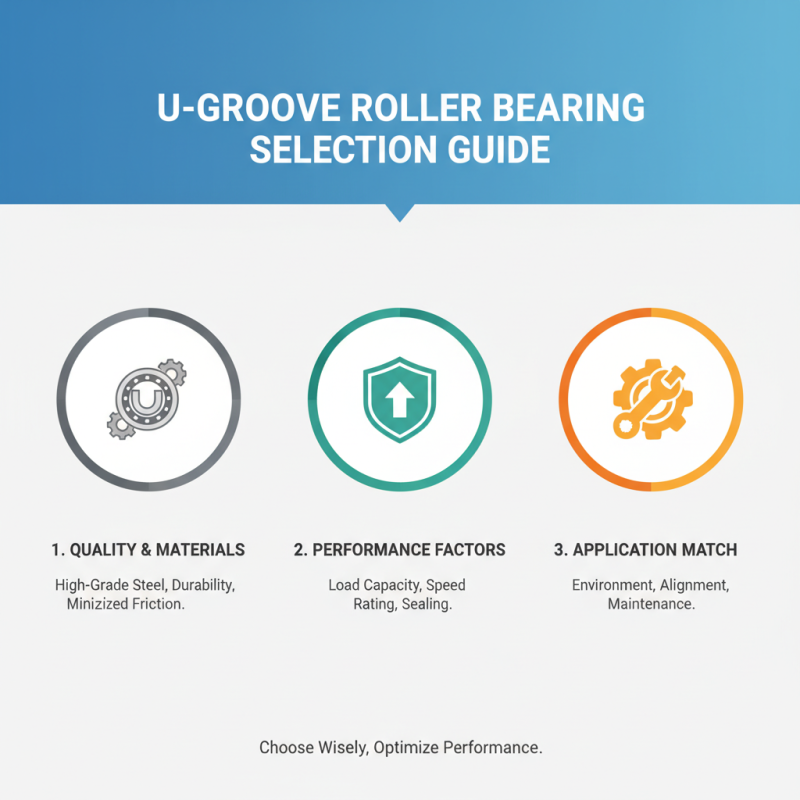

Choosing the best U groove roller bearing can be challenging. With numerous options on the market, it's vital to consider various factors. Quality and materials matter. Look for bearings made from high-grade steel. This enhances durability and performance. A well-constructed bearing minimizes friction and wear.

When selecting a U groove roller bearing, think about size and load capacity. Measure the required dimensions precisely. An improper fit can lead to premature failure. Don't forget to check the bearing’s compatibility with your application.

Tips for buying include assessing customer reviews. These insights provide real-world performance details. Additionally, consider the manufacturer's warranty. A solid warranty reflects confidence in product quality. Remember to think about maintenance as well. Regular inspection can prolong the bearing's life. Avoid overlooking these essential steps.

Proper maintenance is vital for U groove roller bearings. Regular inspection can prevent untimely failures. Check for any signs of wear or damage frequently. A small crack or discoloration can hint at deeper issues. Pay attention to noise and vibration during operation. Unusual sounds often signal a problem.

Lubrication is crucial too. Use the recommended type of grease and apply it according to guidelines. Too much or too little can lead to complications. Over time, contaminants may accumulate, affecting performance. Clean the bearings periodically. A simple wipe can make a significant difference.

Heat buildup can be a concern, especially in high-speed applications. Monitor operating temperatures closely. If they rise too quickly, shut down the system. It’s a signal that maintenance is overdue. Ignoring these signs could lead to costly repairs. It's essential to reflect on maintenance habits. Small changes can yield significant benefits in the long run.

This chart compares the load capacity of different types of U Groove roller bearings. Understanding the load capacity helps in selecting the right bearing for specific applications, ensuring optimal performance and longevity.

U groove roller bearings can be quite effective, but they aren't without their issues. One common problem is wear due to misalignment. This can happen when the bearing is not installed correctly. You might notice unusual noise or vibration during operation. These signs should not be ignored. They often indicate that it's time for a troubleshooting session.

Another frequent issue is insufficient lubrication. A lack of proper grease can lead to overheating and premature failure. If you observe that your bearings are running hotter than usual, this could be the cause. Regular inspection is crucial here. Over-lubrication can also create problems. Too much grease can trap dirt and debris.

Finally, consider the bearing's loading conditions. Overloading can lead to deformation. It's essential to know the weight the bearings can handle. Always refer to guidelines, as exceeding these limits can result in serious problems. Pay attention to performance and intervene early to extend the life of your bearings.