In the world of machinery, the role of "Bearing Roller Cylindrical" types is pivotal. Experts emphasize their importance for various applications. According to Dr. John Simmons, a renowned expert in bearing technology, "Understanding bearing types is key to improving efficiency." This statement resonates strongly, especially as industries evolve.

Cylindrical roller bearings offer unique advantages. They are designed to handle heavy radial loads. Their structure enables high-performance in limited space. However, some experts suggest that many overlook their maintenance needs. Ignoring these requirements can lead to unscheduled downtimes and costly repairs.

Further exploration reveals that choosing the right type is crucial. It can influence the overall performance of machinery. While many appreciate the value of "Bearing Roller Cylindrical" types, misconceptions still exist. Users must educate themselves on these differences to enhance reliability in their systems. Engaging with professionals and exploring detailed insights can bridge this knowledge gap.

Cylindrical roller bearings are essential in various applications. They feature a cylindrical shape that allows them to carry heavy loads. These bearings are designed to handle both radial and axial loads effectively. Their configuration permits less friction and improved performance.

Different types of cylindrical roller bearings exist. For example, single-row bearings are popular in several industries. They offer high radial load capacity but limited axial load handling. Double-row bearings can support heavier loads and provide better stability. They are suitable for use in gearboxes and machinery.

Tips: When choosing bearings, consider load capacity and space. Some designs may require more room. Always check dimensions carefully. Maintenance is crucial for longevity. Regular lubrication can prevent premature wear. Overlooking these details can lead to costly downtime. Each bearing has its unique purpose, so don't rush in. Make sure to evaluate options thoroughly.

Cylindrical roller bearings play a crucial role in various industries. They are known for their ability to support heavy loads and withstand high speeds. This makes them essential in manufacturing, aerospace, and automotive sectors.

In manufacturing, these bearings help machines run smoothly and efficiently. They reduce friction, which increases the lifespan of machinery.

In the aerospace industry, cylindrical roller bearings are used in engines and landing gear. Their design allows them to endure extreme conditions. However, proper maintenance is often overlooked. Routine checks can prevent failures, saving time and money. In automotive applications, these bearings are key in transmission systems, ensuring stability and performance.

Despite their advantages, cylindrical roller bearings can sometimes fail due to misalignment or improper installation. This highlights the importance of skilled technicians for their installation and upkeep. Without this expertise, even the best bearings can underperform. Therefore, understanding the specific requirements of each application is vital. This awareness can lead to better performance and reliability in the long run.

Cylindrical roller bearings offer distinct advantages in various applications. Their design allows for high radial load capacities, making them ideal for heavy machinery. They can support large amounts of weight while maintaining smooth operation. This efficiency can enhance productivity in manufacturing processes, leading to higher output.

One of the key benefits of these bearings is their ability to minimize friction. They feature a line contact between the rollers and raceways. This design results in less wear and tear compared to other types, which can be cost-effective in the long term. However, achieving proper alignment is crucial. Misalignment can lead to uneven wear, compromising their performance. Regular maintenance is necessary to optimize lifespan.

Cylindrical roller bearings are also adaptable. They can be utilized in various environments, from automotive to industrial. That said, their performance can vary significantly based on application. One must remain vigilant with installation procedures. A mistake here may lead to significant issues down the line. Users should carefully consider their specific requirements. This attention to detail will ensure that the benefits outweigh any potential drawbacks.

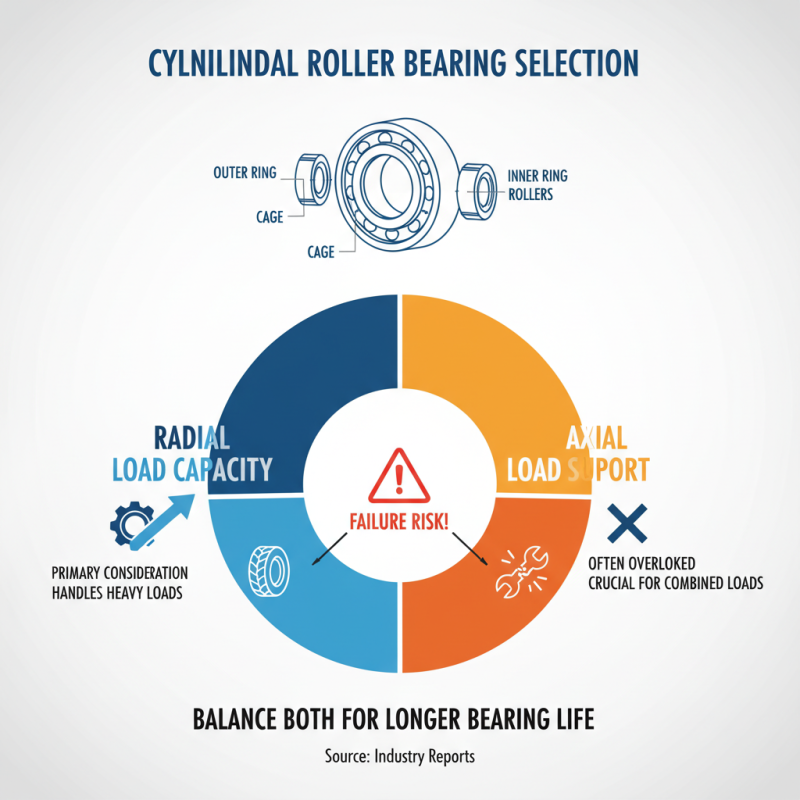

When selecting cylindrical roller bearings, several key factors must be taken into account. Load capacity is essential. According to industry reports, these bearings can handle radial loads effectively. However, users often overlook the importance of axial load support. This can lead to premature failure in applications demanding both radial and axial strength.

Another important consideration is the lubrication method. Using the right type of lubrication enhances performance and lifespan. A study noted that improper lubrication causes up to 40% of bearing failures. Yet, many manufacturers do not provide adequate guidance on lubrication schedules. This gap can result in increased maintenance costs over time.

Temperature range is frequently disregarded. High temperatures can degrade bearing materials. Users must examine the operating conditions carefully. Reports indicate that a 10°C rise in temperature can reduce the lifespan significantly. However, many users fail to factor this into their selection process. Balancing these considerations can feel daunting. It's crucial to assess the specific demands of your application to avoid long-term issues.

Cylindrical roller bearings require careful maintenance to ensure optimal performance. Regular inspections are crucial. Look for signs of wear, such as discoloration or pitting on the rollers. These indicators can signal potential failures. It's advisable to check the lubrication levels frequently. Insufficient lubrication leads to increased friction and heat. This can result in damage over time.

Cleaning is another necessary task. Sometimes, dirt and debris accumulate in the bearings, affecting efficiency. Use appropriate cleaning solutions and methods to keep them free of contaminants. However, be cautious; improper cleaning can cause more harm than good. If you’re unsure, consulting a professional is a wise choice.

Lubrication techniques often vary. Some prefer grease while others might use oil. Each type has advantages and disadvantages. Experimenting with both can lead to better outcomes for specific applications. Remember, maintenance is not just a task, but a learning process. Understanding your bearings takes time and patience.

This chart illustrates the distribution of various cylindrical roller bearing types and their common applications. The data represents the percentage usage of each type in various industries.