Steel Ball Bearings are essential components in various machinery today. They play a crucial role in enhancing movement efficiency. In 2026, the latest features of these bearings will bring new advancements.

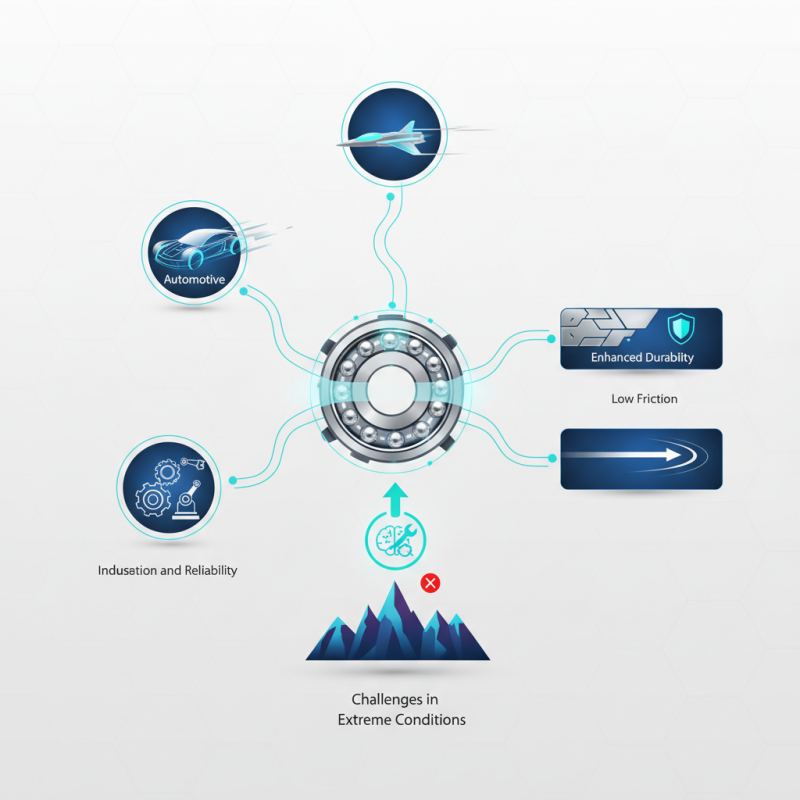

The design of Steel Ball Bearings is constantly evolving. Enhanced durability and low friction are notable improvements. These features significantly reduce wear and tear, extending their lifespan. However, manufacturers still face challenges in optimizing performance under extreme conditions.

Applications of Steel Ball Bearings are diverse. They are found in automotive, aerospace, and industrial machinery. Each industry requires specific characteristics in bearings. This highlights the importance of tailored solutions. As we explore these features and uses, we must reflect on the balance between innovation and reliability. The journey of Steel Ball Bearings continues, with room for growth and improvement.

Steel ball bearings play a crucial role in various industries. These precision parts reduce friction and wear in machinery. In 2026, trends are shifting towards improved materials and designs. Many manufacturers seek enhanced durability and efficiency. The focus now is on sustainability while maintaining performance.

The industry faces challenges. Not all steel ball bearings meet the required standards. This inconsistency can lead to increased maintenance costs. Furthermore, environmental regulations are tightening. Companies must rethink their production methods. The demand for eco-friendly materials is rising. Plastic or hybrid bearings are becoming more popular. Yet, their performance often struggles in high-load applications.

Despite these challenges, advancements continue. Innovations in manufacturing techniques are on the rise. 3D printing has opened new possibilities in bearing design. However, quality control remains a concern. Poor quality control can result in failures. Therefore, each step in the manufacturing process requires careful oversight. As the industry evolves, adapting to new technologies will be essential.

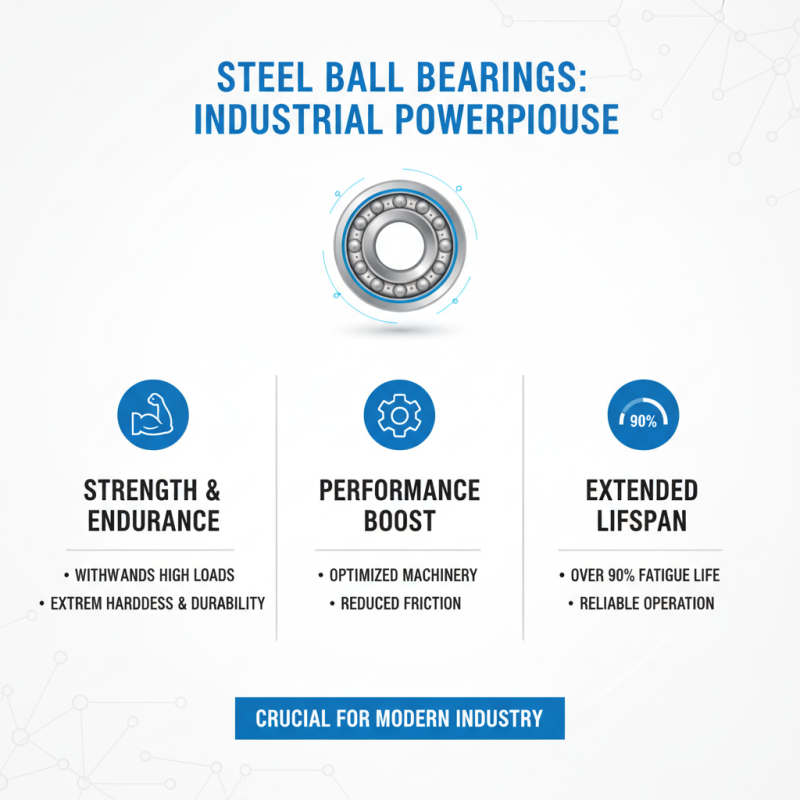

Steel ball bearings have become vital components in various machinery. Their features significantly enhance performance across industries. The hardness and durability of steel allow these bearings to withstand high loads. According to industry reports, these bearings can handle more than 90% of the fatigue life under normal operating conditions.

Key characteristics include low friction and high precision. This combination promotes smoother operation and extends the lifespan of machinery. In fact, a study indicated that high-precision steel ball bearings reduce energy consumption by up to 20%. They also maintain structural integrity in extreme environments.

Tips for Selection: Always consider the operating temperature range. Ball bearings can warp under excessive heat. Consulting reports about load ratings can ensure informed purchasing decisions. Remember, not all steel bearings meet the same specifications. Some may not thrive in specific applications. Choose wisely to avoid premature failures. The right choice can make a significant difference in efficiency and longevity.

Steel ball bearings play a crucial role in various industries. They provide efficient motion and reduce friction. In automotive applications, they are essential. These bearings enable smooth rotation in engines and gear systems. Over time, wear can occur, leading to potential failure. Inspecting these components regularly is vital.

In manufacturing, steel ball bearings are common in conveyor systems. They ensure quick and reliable movement of products. However, heavy loads can cause damage. Choosing the right bearing can be challenging. Engineers must account for load capacity and environmental conditions.

In the aerospace sector, precision is key. Steel ball bearings are employed in critical components. Any malfunction can lead to disastrous consequences. Therefore, they must meet strict quality standards. Regular testing and maintenance are necessary to mitigate risks. This ensures safety and reliability in flight operations.

Steel ball bearings are widely used in various applications, thanks to their excellent durability and performance. They are often compared to other bearing types, such as roller bearings and plain bearings. Each type has its own advantages and disadvantages, influencing their suitability for different situations.

When it comes to load capacity, steel ball bearings excel in handling both radial and axial loads. Their spherical shape provides a low-friction surface for smooth rotation. However, in very heavy-load applications, roller bearings might perform better. They can bear heavier loads with less deformation. This makes them ideal for industrial machinery. On the flip side, steel ball bearings can be more affordable and easier to source.

While steel ball bearings are versatile, they may not always be the best choice. In environments with extreme temperatures, for instance, their performance can degrade. Moisture and corrosion may also impact their longevity. Users must consider these factors when selecting the right bearing type. The decision is not always straightforward. Each application has unique demands that require careful thought.

As we look ahead to 2026, the steel ball bearing industry is poised for significant advancements. According to a recent market report, demand is projected to grow by 5% annually, driven by industrial automation and renewable energy sectors. The increasing need for energy-efficient solutions pushes manufacturers to develop bearings that can withstand higher loads while minimizing friction.

Emerging trends indicate a shift toward hybrid materials. These innovations combine steel with ceramics, enhancing performance and longevity. Additionally, advancements in surface treatment technologies improve corrosion resistance. The integration of IoT is also notable, allowing for real-time monitoring of bearings. This data-driven approach enables better maintenance planning and reduced downtime. Despite these advancements, challenges remain. Not all manufacturers can keep up with rapid technological changes. The gap between innovation leaders and laggards is growing, raising questions about sustainability in practices.

Moreover, while tech advancements promise to improve efficiency, they also bring complexities. New designs may require extensive retraining for engineers and technicians. The industry must reflect on how to facilitate this transition effectively. Keeping pace with innovation is critical, but so is ensuring a well-prepared workforce. Balancing these aspects is not easy, yet essential for future success.

| Feature | Description | Current Use | Future Trends |

|---|---|---|---|

| High Precision | Manufactured to tight tolerances for accurate performance. | Aerospace applications. | Enhanced manufacturing methods for even tighter tolerances. |

| Corrosion Resistance | Coatings or materials that resist rust and wear. | Marine and outdoor machinery. | New surface treatment technologies to improve longevity. |

| Low Friction | Designed to minimize energy loss and increase efficiency. | Electric vehicle motors. | Advanced lubrication techniques to reduce friction further. |

| Temperature Tolerance | Able to function effectively under high heat conditions. | Industrial equipment and machinery. | Innovative materials that withstand extreme temperatures. |

| Material Innovation | Use of advanced alloys and composites for strength. | Heavy-duty applications in construction. | Adoption of nanotechnology for improved material properties. |