As the industry evolves, Grooved Ball Bearings are experiencing exciting innovations. Advances in design and manufacturing techniques are reshaping their use. The demand for performance and efficiency leads to new trends that promise improved functionality.

The rise of automation and robotics drives the need for high-quality bearings. Grooved Ball Bearings, known for reduced friction, enhance operating efficiency. Recent developments focus on materials that withstand extreme conditions. This progress captures attention in various sectors, from automotive to aerospace.

Yet, challenges remain. Certain traditional methods may hinder adaptability. Manufacturers must strike a balance between innovation and reliability. Observing market responses is crucial for guiding future improvements. In this dynamic landscape, Grooved Ball Bearings are set to play a pivotal role.

As we look toward 2026, the advancements in materials for grooved ball bearings are particularly noteworthy. One significant development is the increasing use of composite materials. These materials offer higher resistance to wear and corrosion. They also reduce overall weight, which can enhance the efficiency of machinery. However, the sourcing and manufacturing processes for these composites can be complex and costly.

Another promising trend is the experimentation with additive manufacturing techniques. This allows for the production of intricate designs that were previously difficult to achieve. It also minimizes material waste, which is a significant concern in traditional manufacturing methods. Yet, the durability and long-term performance of 3D-printed grooved ball bearings still require rigorous testing and improvement.

Meanwhile, biocompatible materials are gaining traction in specialized applications. They can perform well in harsh environments or where contamination risks exist. However, the challenge lies in balancing material performance with environmental sustainability. It remains crucial to evaluate the lifecycle impacts of these materials thoroughly. In this rapidly evolving landscape, innovation must be approached with caution and thoughtfulness.

This chart showcases the projected market trends for various materials used in grooved ball bearings by 2026. The data reflects advancements in material technologies aimed at enhancing performance and durability.

In the realm of manufacturing, grooved ball bearings have seen remarkable advancements. The demand for precision and efficiency drives continuous innovation. Advanced techniques like additive manufacturing are reshaping the landscape. These methods allow for the creation of complex geometries that traditional machining can't achieve. However, challenges persist in achieving optimal material properties.

Moreover, surface treatments are becoming more sophisticated. Coatings enhance durability and reduce friction. Techniques like laser engraving add unique identifiers to each bearing, improving traceability. Still, some processes may introduce inconsistencies that require careful monitoring. Manufacturers need to invest in quality control, ensuring that each product meets stringent standards.

Additionally, integration of sensors in bearings is on the rise. These sensors can detect wear and monitor performance in real-time. But, embedding technology may complicate the design and increase production costs. Finding the right balance between innovation and practicality remains essential. Ultimately, as manufacturers push boundaries, they must reflect on these complexities and continuously adapt to remain competitive.

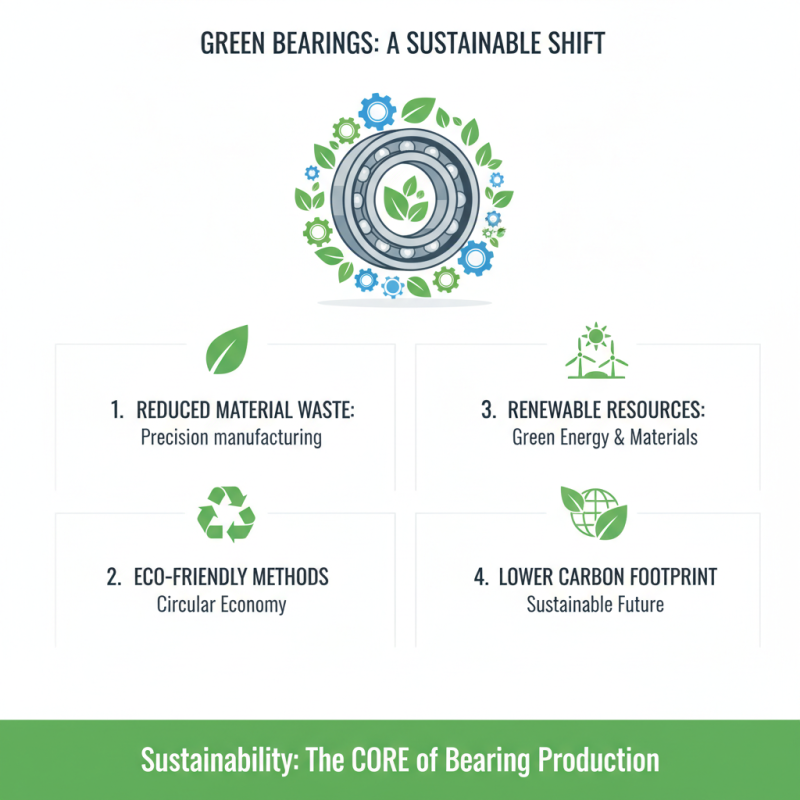

Sustainability is becoming central in grooved ball bearing production. Innovations focus on reducing material waste. Companies now seek eco-friendly methods. They explore renewable resources in manufacturing. This shift can reduce the industry's carbon footprint significantly.

Recycled metals are gaining popularity. They lower the environmental impact. However, not all recycled materials meet the necessary quality standards. Finding the right balance between sustainability and performance is crucial. Some manufacturers struggle with this adjustment.

Energy-efficient production processes are another focus area. Technologies that consume less power are now prioritized. Yet, initial investment costs can hinder widespread adoption. Many companies are still hesitant. The journey towards sustainability may be slow, but each step counts.

In 2026, the integration of smart technologies and IoT within grooved ball bearings will redefine efficiency and performance. Sensors embedded in the bearings will monitor temperature, vibration, and lubrication levels in real-time. This data provides valuable insights into the operation, enabling predictive maintenance. Users can receive alerts before failures occur. Imagine a factory where machines communicate directly with maintenance crews, minimizing downtime.

However, the implementation of these technologies is not without challenges. Not all bearings can easily accommodate smart features. There might be issues related to power supply and environmental conditions. Wireless connections could face interference. Ensuring data security is another concern that needs attention. Are manufacturers prepared for the potential cybersecurity risks?

Ultimately, while the promise of smarter ball bearings is exciting, careful consideration is essential. Not every innovation will fit every application. The adoption of IoT must be strategic. Balancing traditional engineering practices with new technologies will be critical for success. Users must evaluate their specific requirements and potential obstacles in this evolving landscape.

The world of grooved ball bearings is evolving. In 2026, performance enhancements focus on reducing friction and improving durability. New materials are being explored to achieve these goals. Advanced composites are becoming a popular choice. They offer lightweight options without sacrificing strength.

Manufacturers are also experimenting with optimized geometries. These changes can lead to better load distribution. The result is longer-lasting bearings, which can handle greater stresses. However, some designs may face challenges in specific applications. It’s essential to test these innovations thoroughly in real-world settings.

Adopting advanced technologies like computer simulations can drive improvements. However, there’s a risk of focusing too much on theory. Real-world performance can diverge from simulations. Continuous feedback is crucial in this development phase. Ensuring the bearings perform well in diverse conditions remains a key objective. The journey to enhance performance is ongoing, with lessons learned along the way.