As the demand for precision and reliability escalates, U Groove Roller Bearings are gaining significant attention in various industries. According to a recent report by MarketsandMarkets, the bearing market is projected to reach $107.8 billion by 2026, highlighting the technological advancements driving this growth. U Groove Roller Bearings play a critical role in applications that require smooth and efficient movement, such as robotics, conveyor systems, and automotive components.

These bearings offer unique advantages, including low friction and high load capacity. However, challenges remain in material durability and cost-effectiveness. In many cases, manufacturers struggle to balance performance with affordability. This ongoing need for innovation presents an opportunity to rethink designs and materials used in U Groove Roller Bearings.

The upcoming trends in 2026 will likely focus on smart bearings integrated with IoT technology. These developments could empower users with real-time data on bearing performance, potentially reducing failure rates. Nevertheless, as the industry evolves, stakeholders must address existing shortcomings and redefine standards to ensure the reliability of U Groove Roller Bearings in the future.

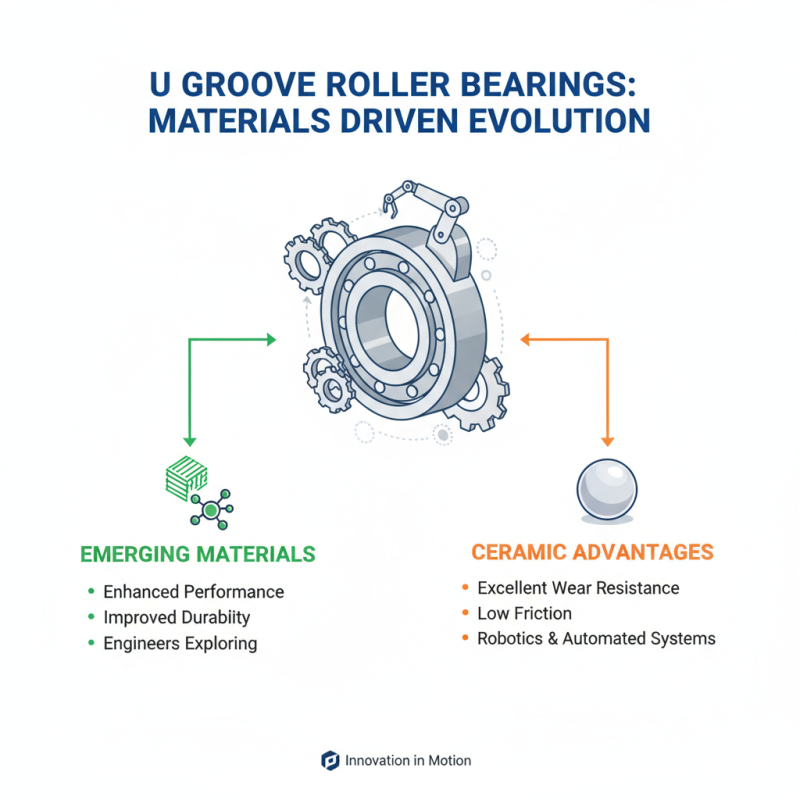

The development of U Groove roller bearings is significantly influenced by emerging materials. These materials promise enhanced performance and durability. Engineers are exploring advanced composites and alloys to improve bearing efficiency. For example, ceramic materials provide excellent wear resistance. They also exhibit low friction characteristics. These properties are attractive for applications in robotics and automated systems.

Another noteworthy material is high-performance polymers. They offer lightweight solutions that can withstand significant loads. Such polymers can operate effectively in harsh environments. However, their long-term performance in heavy-duty applications raises questions. Continuous testing and innovation are necessary to ensure reliability.

Research into hybrid materials is also gaining traction. Combining metals with polymers may yield superior results. These hybrids could offer both strength and reduced weight. However, compatibility issues persist, making this approach a challenge in design and manufacturing. The journey towards optimal materials in U Groove roller bearings is ongoing and complex.

In 2026, U Groove roller bearings are set to revolutionize multiple industries. Innovative designs focus on enhancing load capacity while minimizing friction. According to a recent market report, the U Groove roller bearing market is expected to reach $500 million by 2026. This surge is driven by advancements in materials and engineering.

One key trend is the use of high-performance polymers in bearing designs. These materials reduce weight and improve wear resistance. Manufacturers are also exploring hybrid bearings that combine ceramics and metals. This approach offers better thermal stability, leading to longer product life. However, these innovations come with challenges. For example, cost constraints may limit their widespread adoption among smaller enterprises.

Additionally, the application of smart technologies is gaining traction. Incorporating sensors into U Groove bearings could provide real-time monitoring and predictive maintenance. This technology could prevent unexpected failures and reduce downtime. Yet, the complexity of these systems may pose a barrier for some users. Balancing innovation with usability is essential for sustained growth in this sector.

U Groove roller bearings are increasingly vital in various industries due to their unique design and functionality. These bearings provide smooth motion in applications where space is limited. They excel in situations requiring lateral load support, making them ideal for equipment like conveyor systems and automated machinery. As reported by industry analysts, the demand for U Groove roller bearings is expected to grow by 7% annually over the next five years. This growth reflects their critical role in enhancing operational efficiency.

In the automotive sector, U Groove roller bearings contribute to improved performance in vehicles. They help reduce friction in systems such as sliding doors and window mechanisms. Furthermore, the packaging industry benefits from these bearings, especially in conveyor systems where they guide and support products smoothly. Interestingly, while these bearings are efficient, some users report challenges with wear and tear. Regular maintenance is key to addressing these issues.

In robotics and automation, these bearings support complex movements. While they enhance precision, the cost-benefit balance needs careful consideration. Users must weigh performance gains against potential maintenance costs. With advancements predicted to reshape application areas, ongoing reflection on these bearings' integration remains crucial for maximizing their benefits.

The landscape of U groove roller bearing technology is evolving rapidly as manufacturing processes advance. Innovations in materials and techniques are enhancing the performance of these components. For instance, 3D printing is becoming a popular method in producing intricate designs. This allows for greater customization and precision compared to traditional manufacturing methods.

Another important shift is the adoption of automated processes. Robots and machine learning are streamlining production. They improve consistency and reduce human error in assembly lines. However, this also presents challenges. The transition to automation requires training and adjustment. Not all workers adapt smoothly to the new systems, leading to potential gaps in skills.

Sustainability is gaining attention in the bearing industry. More manufacturers are exploring eco-friendly materials. These choices can reduce the negative environmental impact. Yet, there are trade-offs to consider. New materials may not always offer the same performance or durability as conventional options. Balancing innovation and practical performance remains a complex task for designers and engineers.

The trend towards sustainability in U groove roller bearing technology is more than a buzzword. It reflects a growing commitment within the industry to eco-friendly solutions. Recent data shows that over 40% of companies are prioritizing sustainable practices. This shift affects material choices, design methodologies, and production processes. For instance, using recycled metals in bearing manufacturing can significantly reduce carbon footprints.

Tips: Consider the lifecycle of materials. Opt for suppliers who prioritize sustainability. This choice can enhance your brand's image while supporting the planet.

Advancements in tribological technologies are crucial. New coatings improve efficiency and durability. This innovation also reduces the need for lubrication, decreasing environmental contamination. Reports indicate that a 10% increase in efficiency can lead to substantial energy savings.

Tips: Regularly assess the performance of your bearings. Keeping equipment well-maintained can extend product life, reducing waste.

Stakeholders in the bearing industry face challenges. Balancing performance with eco-friendliness requires innovative thinking. Limiting waste and improving recycling pathways remain critical areas for development. Only time will reveal whether these trends drive widespread change.