In the fast-evolving world of engineering, the Double Groove Ball Bearing stands out as a significant advancement. Designed for improved performance, these bearings play a crucial role in various machinery. They enhance operational efficiency and reduce friction, which is vital for longevity. Engineers often praise their reliability.

The unique design of the Double Groove Ball Bearing allows for better load distribution. This leads to smoother rotations and less wear and tear. Many industries have adopted this technology, from automotive to aerospace. Yet, some users hesitate, questioning their long-term benefits.

Despite their advantages, challenges remain. The initial cost may deter smaller companies. Additionally, some still rely on traditional bearings. The transition requires careful consideration. Users must weigh the benefits and the learning curve involved. Embracing this technology might lead to operational breakthroughs, but it demands a shift in mindset.

Double groove ball bearings present several advantages compared to traditional bearings. Their design allows for increased load capacity and better distribution of stress. According to a recent industry report, these bearings can handle up to 30% more load than single groove options. This improvement leads to longer service life in critical applications.

Efficiency also sees a boost with double groove designs. They reduce friction significantly, enhancing overall performance. A study indicated that friction reduction could be up to 15% in specific settings. This efficiency translates to lower energy consumption and reduced operating costs. However, manufacturers should be cautious about potential overheating due to higher loads. Monitoring is essential in high-performance scenarios.

There are concerns regarding compatibility with existing systems. Some machinery might not support this upgraded design. Additionally, installation may require specialized knowledge. Ensuring that these bearings work optimally in your setup can be challenging. Nevertheless, the shift to double groove ball bearings promises significant benefits when executed thoughtfully.

| Feature | Double Groove Ball Bearings | Traditional Bearings |

|---|---|---|

| Load Capacity | Higher radial load capacity due to double groove design | Lower radial load capacity |

| Friction | Lower friction due to improved alignment | Higher friction |

| Durability | Longer lifespan due to better load distribution | Shorter lifespan |

| Maintenance | Reduced maintenance requirements | Higher maintenance needs |

| Noise Level | Quieter operation | Noisier operation |

| Heat Generation | Less heat due to reduced friction | More heat generation |

| Cost | Higher initial cost but better value over time | Lower initial cost |

Double groove ball bearings are making waves in various industries. Their design promotes enhanced load distribution, which is crucial for the durability of machinery. With a deeper groove, these bearings can handle both radial and axial loads effectively. This versatile performance is significant, especially in applications where space is limited.

The load is distributed more evenly across the balls. This results in reduced stress and longer service life. It’s essential to consider that while they offer numerous benefits, improper installation or selection can lead to failures. The benefits might not always outweigh the risks associated with misuse.

Moreover, these bearings have a better resistance to misalignment. In real-world settings, this can lower maintenance requirements. However, there are instances when they might not perform as expected. Operators must evaluate their specific use cases closely. This careful reflection can lead to more informed choices in bearing applications.

Double groove ball bearings are enhancing machinery performance in 2026. Their design offers improved durability and longevity. This unique feature is vital in industries that rely on precision and reliability. Everyday wear and tear can damage standard bearings quickly. However, double groove ball bearings resist such wear effectively. This leads to longer intervals between replacements, saving time and costs.

To maximize the benefits, regular maintenance is essential. Check for lubrication levels to ensure optimal performance. Over time, lubrication can break down and lead to friction. Periodic inspections can help catch issues early. Consider using advanced lubricants for better protection. A good practice is to document maintenance actions for easier tracking.

In some cases, users report that double groove ball bearings still face challenges. Misalignment or improper installation can cause premature failure. Understanding the installation process is crucial. Each setting might require unique adjustments. Researching specific applications helps in making informed choices. The right fit ensures that the benefits of durability and longevity are fully realized.

Double groove ball bearings are essential in modern industries. Their design allows for better load distribution. This feature is crucial in applications like automotive engineering. These bearings can handle both radial and axial loads efficiently.

In the manufacturing sector, these bearings improve machine performance. They reduce friction and wear, which extends equipment life. In high-speed machines, their stability is especially beneficial. Consider using them in conveyors or robotic arms for added reliability.

Tip: Regular maintenance is vital for optimal performance. Check alignment and lubrication frequently.

Double groove ball bearings also serve the wind energy sector. They support turbine shafts, enhancing efficiency. However, placement must be precise. Incorrect installation can lead to premature failure.

Tip: Always follow installation guidelines to avoid issues. A small mistake can have significant consequences.

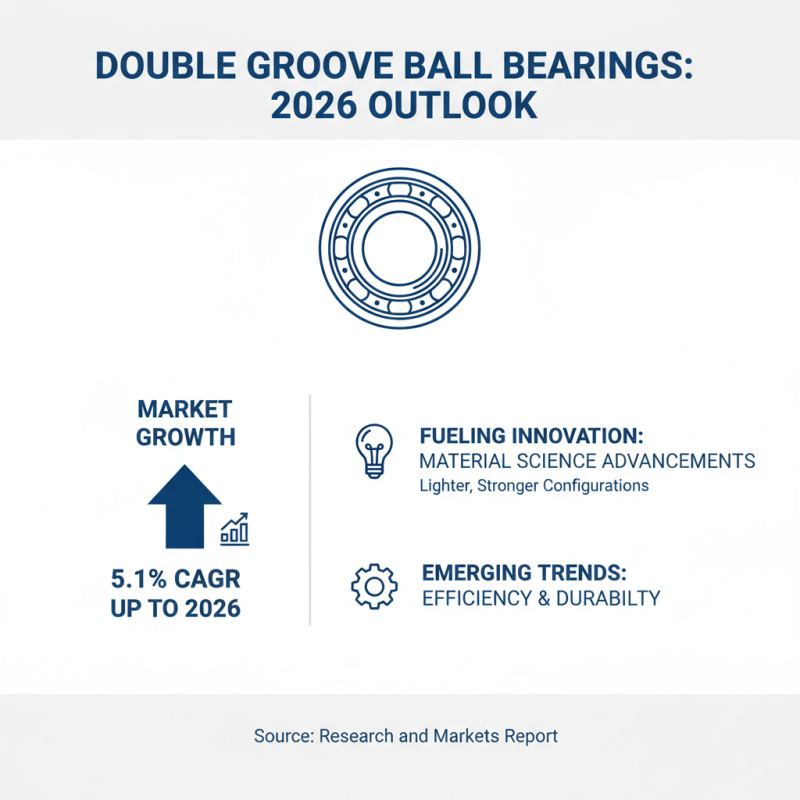

Double groove ball bearings play a vital role in modern machinery, especially as we look towards 2026. Emerging trends indicate a growing emphasis on efficiency and durability. According to a recent market report by Research and Markets, the demand for double groove ball bearings is expected to grow by 5.1% annually through 2026. This growth is fueled by innovations in material science, leading to lighter yet stronger configurations.

Technological advancements are making these bearings more adaptable. Some manufacturers are introducing hybrid designs, combining ceramic and traditional materials. These combinations enhance performance, particularly in high-speed applications. However, there are challenges to consider. Not all designs perform well under varying temperature conditions, highlighting the need for meticulous selection processes. Regular maintenance checks remain crucial to avoid unexpected failures.

It's intriguing to see how predictive maintenance is gaining traction. Sensors embedded in bearings can forecast wear and tear. This proactive approach could reduce downtime significantly. Yet, the technologies must be affordable for all manufacturers. Current cost barriers limit widespread adoption. Innovators must strike a balance between performance and accessibility, ensuring that the benefits of technology reach a wider audience.