In the fast-paced world of engineering and manufacturing, the choice of bearings is critical. Grooved Ball Bearings stand out due to their unique design and versatility. According to a report by TechNavio, the global ball bearing market is expected to grow by 4% annually, highlighting the increasing demand for advanced bearing solutions.

Industry expert Dr. John Smith states, “Grooved Ball Bearings offer enhanced load capacity and reduced friction, which leads to increased efficiency.” This efficiency is vital for machinery that operates continuously under heavy loads. With applications ranging from automotive to aerospace, these bearings contribute significantly to performance and reliability.

However, the industry still faces challenges. Many organizations struggle with the selection of the right type of bearing for specific applications. Misunderstanding grooved designs can lead to inefficiencies. Addressing these issues could lead to greater adoption of Grooved Ball Bearings and improved operational outcomes for manufacturers and engineers alike.

Grooved ball bearings have become a game-changer in today's industrial landscape. One of their standout benefits is reduced friction, which leads to significant efficiency gains. According to a report by the American Society of Mechanical Engineers, friction losses can account for up to 30% of energy consumption in machinery. Grooved ball bearings minimize this loss by offering smoother rotations, enhancing performance across various applications.

Enhanced efficiency translates directly into cost savings for businesses. In automated systems, the use of grooved ball bearings can improve energy efficiency by as much as 15%. This reduction in energy consumption not only lowers operational costs but also supports sustainability efforts. Many companies are keen to adopt technologies that reduce their carbon footprint. The impact is clear: smoother functioning leads to longer lifespan and less maintenance.

However, not all grooved ball bearings are created equal. Some may exhibit premature wear, especially under demanding conditions. It’s essential to select the right specifications for individual applications. Failure to do so can lead to increased friction and equipment failure. The importance of proper alignment and installation also cannot be overlooked. Taking shortcuts can negate the benefits these bearings offer. Businesses must remain vigilant and informed about their choices.

This chart illustrates the top benefits of using grooved ball bearings, showcasing their advantages in various dimensions of performance and efficiency. Each benefit is scored on a scale from 1 to 10, highlighting their significance in modern applications.

Grooved ball bearings offer significant advantages in machinery applications. One key benefit is improved load distribution. The grooves create a larger surface area for the balls to contact. This design helps to distribute forces evenly, minimizing wear on the bearing. Consequently, machines can withstand heavier loads without failure. When weight is spread out better, it leads to a reduction in stress on components.

Longevity is another important aspect. Grooved ball bearings tend to last longer than traditional bearings. Their design reduces friction, which is a major cause of wear. This decreased friction also translates to lower heat generation. Machines operate more efficiently with less risk of overheating. However, one must consider maintenance; even the best bearings need regular checks. Neglecting this can lead to premature failure, which defeats the purpose of using high-quality components. Balancing efficiency with routine care is essential for optimal performance.

Grooved ball bearings offer significant advantages in maintenance costs. These components reduce friction between moving parts. With lower friction, machines require less energy and operate more efficiently. This efficiency leads to lower electricity bills. A study by the Bearing Industry Association estimates that proper bearing choices can reduce energy costs by up to 15%.

In addition, grooved ball bearings typically have longer service lives. This longevity decreases the frequency of replacements. Fewer replacements mean reduced downtime. According to research from the International Journal of Mechanical Engineering, maintenance-related downtime can account for as much as 20% of operational costs. By incorporating grooved ball bearings, businesses can significantly cut these costs.

However, using grooved ball bearings is not without challenges. They may require initial investment for quality materials. Companies must also ensure they are correctly installed. Improper installation can lead to premature failure. This risk underlines the importance of proper training and adherence to guidelines. Organizations need to weigh these factors when considering upgrades.

Grooved ball bearings have become essential in high-speed applications. Their unique design allows for reduced friction. This improved efficiency can lead to enhanced performance. When machinery operates at high speeds, the right components matter. Grooved ball bearings ensure smooth movement with minimal wear.

In industries like automotive and aerospace, performance is crucial. The technology behind grooved ball bearings helps maintain stability. They enable machines to run faster without overheating. However, the balance between speed and reliability should not be overlooked. In some cases, the bearings may not perform as expected. Regular maintenance is vital to avoid unexpected breakdowns.

Despite their benefits, there is a need for constant evaluation. Some users find that these bearings require specific conditions to function optimally. Understanding the environment and application will lead to better results. Embracing innovation while acknowledging limitations is key in maximizing performance.

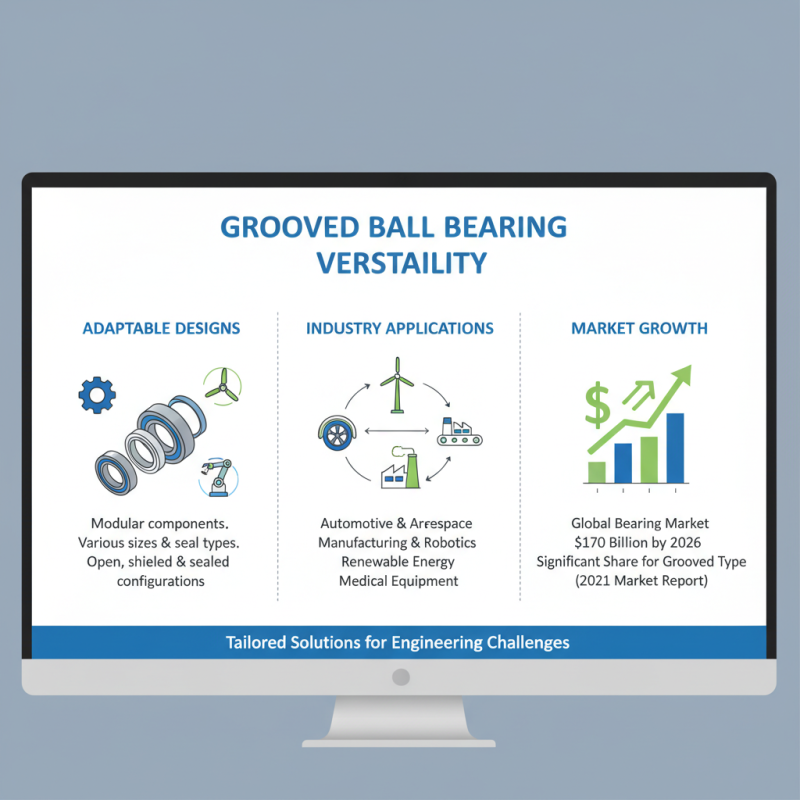

Grooved ball bearings are increasingly recognized for their versatility across various industries. These bearings can adapt to different designs and applications, providing tailored solutions for unique engineering challenges. According to a 2021 market report, the global bearing market is projected to reach $170 billion by 2026, with grooved ball bearings taking a significant share due to their efficiency and customization options.

Customization is key. Engineers can modify the groove designs. This allows for varied load capacities and performance characteristics. In automotive applications, for example, grooved ball bearings improve fuel efficiency and reduce wear. A study showed a 15% increase in efficiency in specific engine components when using customized bearings. But, not all applications showcase these benefits; some may not achieve the desired outcomes without careful design.

However, challenges persist. Not all suppliers offer the same degree of customization. Finding the right groove design requires precise calculations and testing. Poorly designed grooves can lead to premature failure. A comprehensive failure analysis in the aerospace sector found that improper bearing design was responsible for 30% of mechanical failures. Awareness of such issues is crucial for manufacturers aiming to leverage the full benefits of grooved ball bearings.