In the rapidly evolving landscape of industrial applications, the necessity for precision and reliability has made V Groove Bearings an integral component for many engineers and operators. According to Dr. James Smith, a foremost expert in bearing technology, "The adoption of V Groove Bearings significantly enhances operational efficiency by providing unmatched stability and smoothness in motion." This statement underscores the crucial role that these bearings play in ensuring the longevity and reliability of various industrial systems.

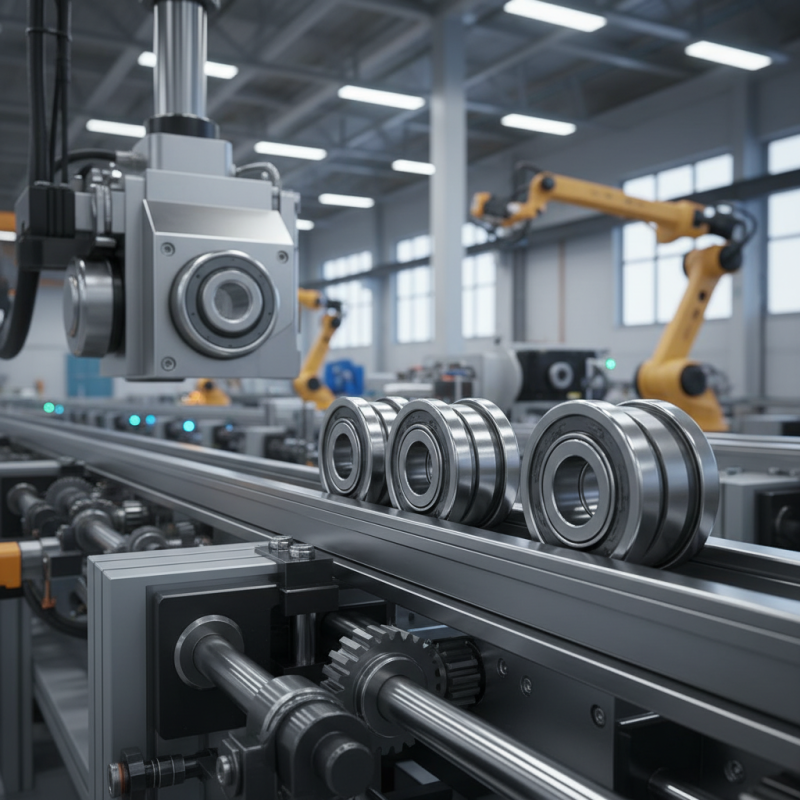

V Groove Bearings are specifically designed to facilitate smooth linear motion along tracks, making them indispensable in applications ranging from conveyor systems to automated machinery. The unique geometry of these bearings allows them to seamlessly navigate through grooves, thereby reducing friction and wear. As industries strive for greater efficiency, the benefits of V Groove Bearings, including improved load distribution and ease of installation, make them a preferred choice for many applications.

As we delve into the top ten benefits of using V Groove Bearings in industrial settings, it becomes evident that their advantages extend beyond mere functionality. Understanding these benefits can lead to enhanced productivity and reduced downtime, ultimately driving innovation and success in various industrial sectors.

V Groove bearings are increasingly recognized for their effectiveness in load distribution across various industrial applications. Their unique design allows them to accommodate misalignment and can handle both radial and axial loads simultaneously. This feature is crucial in applications where precision and stability are paramount, as it minimizes the risk of wear and prolongs the lifespan of the bearing system.

One significant advantage of V Groove bearings is their ability to evenly distribute weight, thereby reducing the stress on individual components. This is particularly beneficial in heavy machinery, where uneven load can lead to premature failure. Additionally, V Groove bearings can provide smoother motion and less friction, further enhancing operational efficiency. As a result, industries can experience increased productivity and reduced maintenance costs.

Tips for optimizing the performance of V Groove bearings include regular inspection for alignment issues and ensuring proper lubrication to minimize friction. Additionally, consider the load capacity and environmental conditions when selecting bearings, as these factors can significantly impact their performance. Taking these steps will not only enhance the functionality of V Groove bearings but also contribute to the overall efficiency of industrial operations.

| Benefit | Description | Impact on Load Distribution |

|---|---|---|

| Improved Load Handling | V groove bearings efficiently distribute loads, minimizing stress on machinery. | Lower stress concentration leads to extended equipment lifespan. |

| Reduced Friction | These bearings provide a smooth rolling action, reducing energy losses. | Less friction results in better load performance and efficiency. |

| Versatility | Suitable for various applications, from conveyor systems to heavy machinery. | Adaptable design allows for efficient load distribution across different setups. |

| High Load Capacity | Designed to handle substantial loads without failure. | Maximizes load-bearing capabilities, ensuring robust performance. |

| Easy Installation | Quick and simple mounting process reduces downtime. | Streamlines load adjustments, maintaining optimal performance. |

| Low Maintenance | Durable materials and designs minimize the need for frequent upkeep. | Consistent load distribution over time without frequent interventions. |

| Vibration Dampening | Helps absorb shocks and vibrations during operation. | Enhances stability, distributing loads more evenly. |

| Temperature Regulation | Effective in managing heat build-up to prevent failures. | Maintains load integrity under varying thermal conditions. |

| Cost-Effectiveness | Long lifespan and reduced maintenance lead to lower total costs. | Efficient load management reduces operational expenses. |

| Enhanced Safety | Built to reduce risk of equipment failure and associated hazards. | Contributes to a safer working environment by ensuring load reliability. |

V groove bearings are designed to withstand significant stresses and high-load conditions, making them a preferred choice in various industrial applications. One of their key advantages is their enhanced durability, which is crucial for machinery that operates under intense pressure. The geometry of V groove bearings allows for better load distribution, ensuring that the bearings can effectively manage weight while maintaining optimal function. This ability reduces wear and tear over time, leading to extended service life and decreased maintenance needs.

Moreover, the material composition of V groove bearings is engineered to resist deformation and failure even in demanding environments. This durability is particularly important in applications where uptime is critical, as breakdowns can lead to costly downtimes and production halts. The ability to maintain performance under high-load conditions not only improves operational efficiency but also contributes to cost-effectiveness. As industries continue to prioritize reliability and performance, the role of V groove bearings in enhancing overall system resilience cannot be overstated.

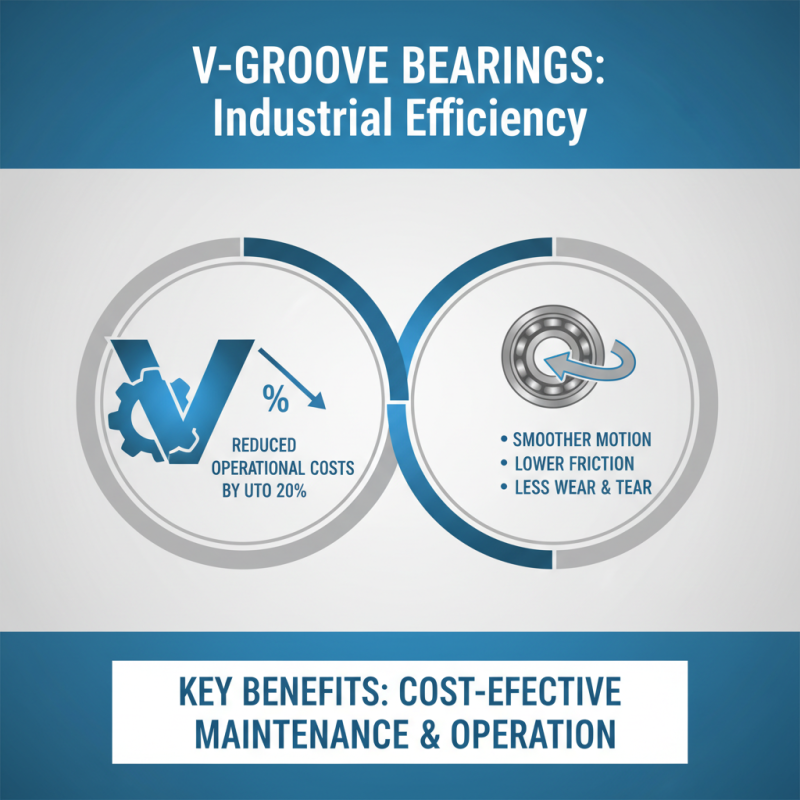

V groove bearings have gained significant attention in industrial applications due to their high efficiency and cost-effectiveness in maintenance and operation. A recent industry report highlights that using V groove bearings can reduce operational costs by up to 20% compared to traditional bearing systems. This cost reduction primarily stems from their ability to facilitate smoother motion and lower friction, which in turn lessens the wear and tear on machinery, translating to less frequent replacements and lower overall maintenance expenses.

Furthermore, the design of V groove bearings allows for easier installation and alignment, reducing labor costs associated with maintenance. According to research from the International Journal of Mechanical Engineering, proper alignment can enhance the lifespan of bearings by 30%, significantly minimizing downtime and improving productivity. Consequently, industries that implement V groove bearings not only benefit from lower maintenance costs but also enhance their operational efficiency, making them an attractive choice for manufacturers looking to optimize their processes.

V Groove bearings are renowned for their unique design that allows for smooth operation across various surfaces, making them an ideal choice for a wide range of industrial applications. Their versatility is showcased in environments like automated machinery, conveyors, and precision equipment where reliable motion is crucial. The ability of V Groove bearings to facilitate linear movement on tracks or rails provides a seamless experience in applications involving heavy-duty machinery or conveyor systems, thus enhancing overall operational efficiency.

In addition to their performance with straight tracks, V Groove bearings excel in applications requiring curved or complex movements. They adapt easily to different alignment configurations, making them suitable for robotic arms and other automated systems that necessitate agility and precision. Their capacity to operate under varying loads and speeds further affirms their role in demanding industrial settings, where reliability and flexibility are paramount for maintaining productivity. Overall, the broad applicability of V Groove bearings across diverse industrial domains highlights their importance as a fundamental component in modern engineering solutions.

This chart illustrates the top 10 benefits of using V groove bearings in industrial applications, highlighting their advantages such as high load capacity, durability, and low friction among others. The data reflects the importance of these bearings in various industrial settings, showcasing their versatility and efficiency.

V groove bearings play a pivotal role in enhancing precision and performance in various industrial applications. These bearings are meticulously designed to accommodate high radial loads while offering smooth movement along guide wheels and tracks. According to a report from the International Journal of Advanced Manufacturing Technology, the use of V groove bearings can improve positional accuracy in machinery by up to 20%, resulting in significantly less downtime and increased operational efficiency. This precision is critical in sectors such as automation and robotics, where even minor deviations can lead to substantial operational setbacks.

Additionally, the performance metrics of V groove bearings are unparalleled when it comes to reducing friction and wear. Industry analyses suggest that utilizing these bearings can lead to a reduction in energy consumption by 15-30%, benefiting both the environment and the operating costs of manufacturing processes. With their optimal load distribution and ability to handle misalignment, V groove bearings not only enhance the lifespan of machinery but also contribute to improved product quality by ensuring consistent and reliable motion. This combination of benefits positions V groove bearings as a crucial component in achieving high-performance standards across various industrial applications.