In the fast-paced world of machinery, optimal performance is crucial. The 2026 Best Ball Bearings Guide addresses this necessity. "The right Bearings Ball can significantly enhance machine efficiency," says Michael Johnson, a renowned expert in the bearings industry. His insights underline the importance of selecting quality components.

Ball bearings reduce friction and improve motion. However, not all Bearings Ball are created equal. Selection requires careful consideration. Factors like load capacity and material directly affect performance. Quality choices minimize wear and increase longevity. Yet, many overlook these details, leading to costly repairs and downtime.

Finding the best Bearings Ball involves navigating various options. It's not a one-size-fits-all solution. Users must reflect on their specific needs. The balance of performance and cost is delicate. Make informed decisions to avoid future regrets.

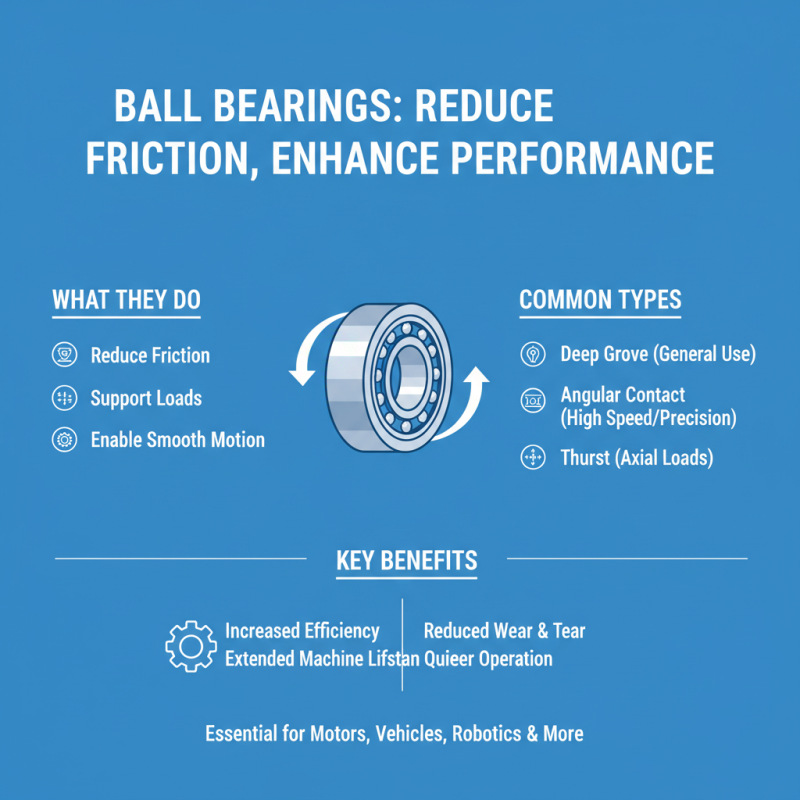

Ball bearings are vital components in many machines. They reduce friction between moving parts and ensure smoother operation. Understanding the types and uses of ball bearings can enhance their performance.

There are several types of ball bearings, each designed for specific applications. Deep groove ball bearings are the most common, often used in electric motors and appliances. Thrust ball bearings handle axial loads well. The choice depends on your application’s needs and environment.

Beyond types, considerations like material and size matter. Not all materials perform well under high temperatures or harsh conditions. It’s important to consider these factors when selecting bearings. Sometimes, people overlook this. Finding the right fit can lead to unexpected performance issues. Prioritizing quality over cost is essential for long-term efficiency.

When selecting ball bearings, several key factors significantly impact their performance. These factors include load capacity, friction, and material quality. A study by the American Bearing Manufacturers Association indicates that bearings with lower coefficient friction perform at least 20% better when loaded. This friction variation can make a significant difference in applications requiring high efficiency.

Material quality also plays a vital role. For example, stainless steel bearings are more resistant to corrosion, while ceramic bearings offer lower weight and higher speed capabilities. However, they can be brittle. It's crucial to consider the specific application. Not all materials suit every environment or load requirement.

Tip: Always evaluate your operating conditions. Consider factors like temperature and exposure to moisture.

Another factor is maintenance. Regular inspections and proper lubrication can extend bearing life. A maintenance strategy can improve performance by reducing wear. Overlooking this aspect often leads to costly downtime.

Tip: Set a maintenance schedule. Regular checks can prevent unexpected failures. Physical inspections can also reveal potential issues early.

When selecting materials for ball bearings, durability and efficiency are crucial. Common materials include chrome steel, stainless steel, and ceramic. Each has its pros and cons. Chrome steel offers high hardness but might corrode. Stainless steel resists rust but may wear out faster under heavy loads. Ceramic materials are lightweight and resist wear. However, they can be brittle.

A report by the National Materials Advisory Board highlights that choosing the right material can improve bearing life by up to 50%. It indicates that over 30% of bearing failures occur due to incorrect material selection. This stresses the need for careful consideration during the planning phase. Overshadowing these choices can lead to increased costs and downtime.

Operating conditions play a significant role. For example, high temperatures can limit the efficacy of steel-based bearings. Meanwhile, the environmental aspects can affect bearing performance. Some materials may react poorly in extreme conditions. Continual assessments and testing are recommended. A balance is necessary to avoid overspending on materials that do not meet application needs.

Proper maintenance of ball bearings is crucial for their longevity and performance. Regular cleaning is essential. Dust and debris can cause wear over time. Use a soft cloth to gently clean the outer surface. Avoid using harsh chemicals. They can damage the bearings.

Lubrication plays a key role as well. Ensure you apply the right type of lubricant. Too little can cause friction, while too much can attract dirt. It's a delicate balance. Regularly check for any signs of corrosion. Rust can build up and compromise functionality.

Temperature control is often overlooked. Extreme heat or cold can affect performance. Store ball bearings in a controlled environment. Even minor changes can have a significant impact. Keep an eye on performance over time. If something feels off, it often is. Regular maintenance is not just recommended; it's necessary for optimal performance.

The following chart illustrates the average lifespan of ball bearings based on different maintenance frequencies. Regular maintenance can significantly enhance the lifespan of ball bearings and improve performance.

When selecting ball bearings in 2026, performance matters. Many users overlook this crucial component. High-quality ball bearings enhance efficiency, reduce wear, and increase longevity. According to recent industry reports, using premium materials in ball bearings can boost performance by up to 30%. This translates into smoother operations for machines and devices.

Many brands offer reliable ball bearings. Pay attention to the type of bearing you choose. Some are designed for high-speed applications, while others excel in heavy-load conditions. Ensure you select the right type based on your needs. Also, consider the lubrication method; it significantly influences operational efficiency. A recent study revealed that proper lubrication can enhance bearing life by up to 50%.

Tips: Always check for compatibility with your equipment. Sometimes, oversizing can lead to poor performance. Regular maintenance is crucial. Clean your bearings and check for wear periodically. This habit prolongs their lifespan and ensures optimal performance. Remember, quality often beats quantity in bearing selection. Investing in the right components saves time and money.