In today’s fast-paced industrial landscape, the importance of high-performance components cannot be overstated. Ceramic Ball Bearings have emerged as a game-changer, offering unparalleled advantages over traditional steel bearings. According to a report by Research and Markets, the global ball bearings market is projected to reach $18 billion by 2024, driven by increasing applications in sectors like automotive, aerospace, and manufacturing. The durability and low friction properties of Ceramic Ball Bearings reduce maintenance costs and downtime, which are critical in maintaining operational efficiency. Their ability to withstand extreme temperatures and corrosive environments further enhances their appeal in modern industries. As businesses increasingly seek sustainable and cost-effective solutions, understanding the key benefits of Ceramic Ball Bearings becomes essential for staying competitive in the evolving marketplace.

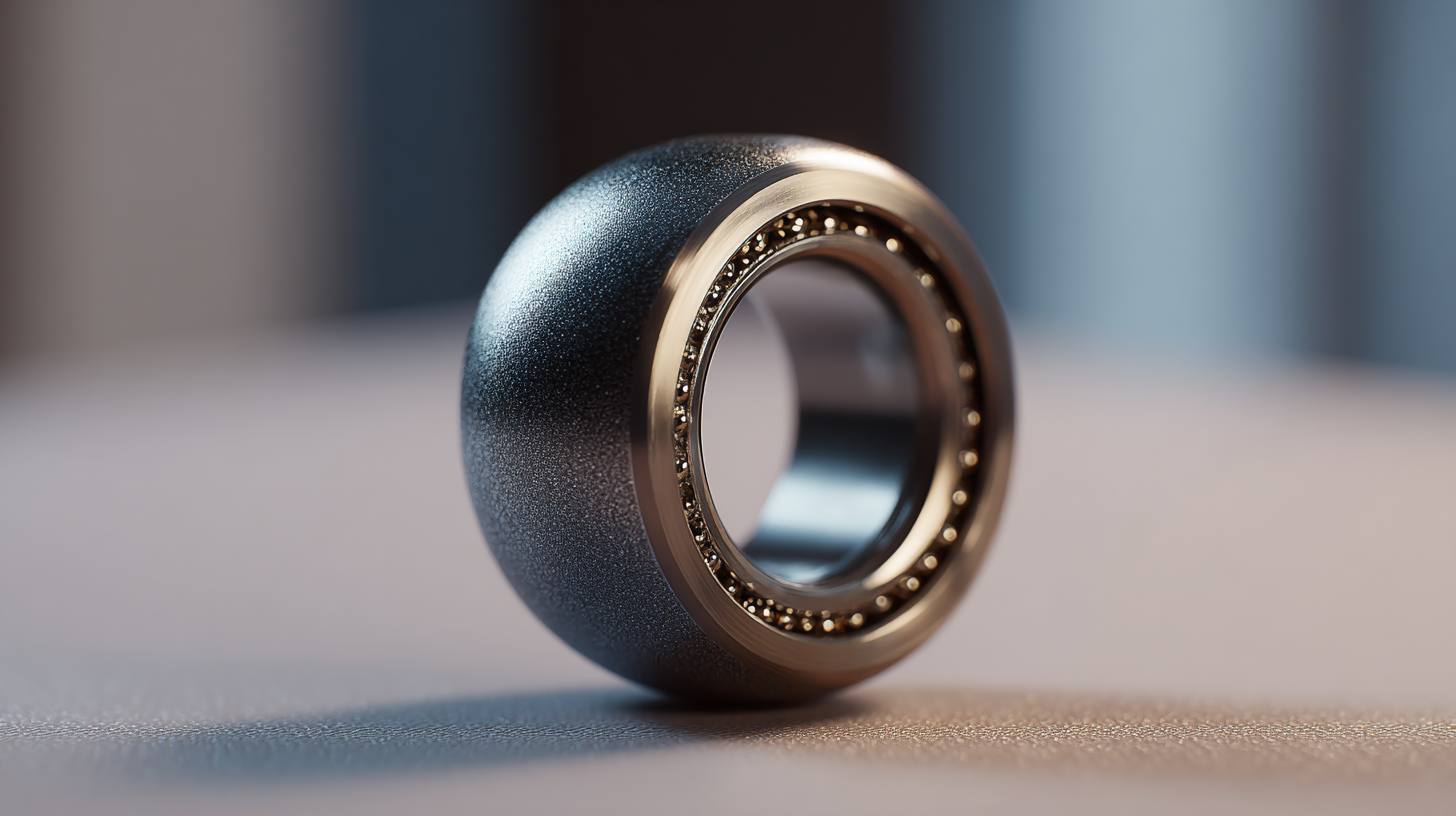

Ceramic ball bearings are gaining popularity in modern industries due to their exceptional durability compared to traditional materials. Unlike steel or metal bearings, ceramic ball bearings are less prone to wear and tear, thanks to their inherent properties. They are made from advanced materials like zirconia or silicon nitride, which resist corrosion and can withstand extreme environmental conditions. This leads to a significantly longer lifespan, reducing the frequency of replacements and maintenance costs, making them a highly cost-effective solution in the long run.

Moreover, the lightweight nature of ceramic ball bearings contributes to their efficiency. They generate less friction during operation, resulting in lower energy consumption and improved performance. This characteristic not only enhances the operational speed of machinery but also minimizes heat generation, leading to less thermal expansion and a more stable performance under varying temperatures. As industries seek more sustainable and reliable solutions, ceramic ball bearings stand out as the superior choice for enhancing the durability and efficiency of their equipment.

Ceramic ball bearings have emerged as a top choice for modern industries, particularly due to their remarkable high-speed performance. Unlike traditional steel bearings, ceramic bearings are made from materials such as silicon nitride, which offers superior hardness and lower density. This unique combination allows them to operate at higher speeds while maintaining lower friction levels. The result is not only enhanced efficiency but also extended service life, making them an economical choice for many applications.

Moreover, the temperature stability of ceramic ball bearings contributes significantly to their high-speed advantage. They can withstand greater heat without compromising performance, which is essential for machinery operating at high rates. This thermal resilience minimizes the risk of failure, ensuring that industrial operations run smoothly and reliably. As industries continue to seek ways to improve productivity and reduce maintenance costs, the shift towards ceramic ball bearings is becoming increasingly evident, solidifying their position in the forefront of modern engineering solutions.

Ceramic ball bearings are becoming increasingly popular in modern industries due to their remarkable ability to reduce friction and enhance efficiency. According to a report by the Research and Markets, the global ball bearings market is projected to reach $22.8 billion by 2027, with a significant portion of this growth attributed to the adoption of advanced materials like ceramics. Traditional steel bearings often suffer from high friction levels, leading to increased energy consumption and frequent maintenance needs. In contrast, ceramic ball bearings can achieve a friction reduction of up to 40%, resulting in smoother operation and longer service life.

The implications of reduced friction are profound, particularly in industries where precision and efficiency are critical. For example, in the aerospace sector, where every ounce of weight and energy efficiency matters, ceramic ball bearings can contribute to fuel savings of approximately 5-10%. Furthermore, studies conducted by the National Aeronautics and Space Administration (NASA) have indicated that utilizing ceramic materials can enhance operational capabilities in extreme conditions, emphasizing their potential in improving overall system performance. As industries look to innovate and minimize costs, the integration of ceramic ball bearings stands out as a strategic choice for enhancing efficiency and reliability.

Ceramic ball bearings are increasingly recognized as a superior choice for modern industries, particularly in environments where corrosion poses a significant threat. Unlike traditional metal bearings, ceramic materials are inherently resistant to rust and degradation, making them ideal for applications in adverse conditions, such as chemical processing and marine environments. Their ability to withstand harsh chemicals without corroding ensures that machinery runs smoothly and requires less maintenance over time.

Tips: When selecting ceramic ball bearings for specific applications, consider the operating temperature and the type of environment. High-performance ceramic bearings are available in variations that can handle extreme temperatures, enhancing their durability and longevity. It’s also essential to assess the lubrication requirements, as some ceramic materials can perform effectively even in dry conditions, reducing the need for regular maintenance.

Moreover, the lightweight properties of ceramic bearings contribute to reduced energy consumption and improved efficiency in machinery. Industries that prioritize environmental sustainability will find that ceramic bearings not only extend the lifespan of their equipment but also minimize waste and the ecological footprint. By investing in ceramic ball bearings, businesses can enjoy the dual benefits of robust performance and eco-friendliness.

Ceramic ball bearings have emerged as a formidable choice for modern industries, particularly due to their cost-effectiveness and long-term savings. Unlike traditional steel bearings, ceramic bearings boast significantly lower friction coefficients, which leads to reduced energy consumption during operation. This translates into lower operational costs, especially for machinery that runs continuously. The durability of ceramic materials also means fewer replacements, decreasing maintenance expenses over time. Industries that rely heavily on rotating equipment, such as automotive and aerospace, can especially benefit from these savings.

Moreover, ceramic ball bearings are resistant to wear, corrosion, and extreme temperatures, which enhances their longevity compared to their metal counterparts. This resilience not only extends the lifespan of the bearings themselves but also contributes to the overall lifespan of machinery. In environments prone to contaminants or harsh conditions, the reliability of ceramic bearings means fewer production downtimes and enhanced productivity. By investing in ceramic ball bearings, companies can ensure smoother operations and substantial cost savings in the long run, illustrating their value as a strategic choice for modern industrial applications.

| Reason | Description | Estimated Long-Term Savings (%) |

|---|---|---|

| Reduced Friction | Ceramic materials have lower friction coefficients, leading to less energy consumption. | 20% |

| Longer Lifespan | Ceramic ball bearings outperform steel in lifespan due to wear resistance. | 30% |

| Maintenance Reduction | Lower frequency of maintenance leads to reduced operational downtime. | 25% |

| Corrosion Resistance | Resistance to corrosive environments reduces replacement costs. | 15% |

| High Temperature Tolerance | Better performance in high-temperature settings prevents failures. | 18% |