In the evolving landscape of machinery, the choice of components is crucial. Bearing Roller Tapered has gained attention for its unique benefits. Industry expert, Dr. Emily Hart, once stated, "Tapered roller bearings offer precision and reliability in demanding applications." This insight highlights the pivotal role these bearings play in ensuring optimal machinery performance.

When selecting components, many overlook the advantages of Bearing Roller Tapered. These bearings accommodate both radial and axial loads effectively. For instance, their design allows for efficient weight distribution. However, it often requires careful consideration of dimensions and fit. Balancing performance with cost can be challenging. Users may find themselves questioning the long-term value versus the initial investment.

While Bearing Roller Tapered solutions present numerous benefits, some inefficiencies can arise. Misalignment or installation errors can lead to premature wear. Maintaining these bearings is essential for achieving maximum performance. Therefore, investing in proper training and resources becomes vital for users. The complexity of this choice requires reflection and informed decision-making.

Tapered roller bearings are essential in many machinery applications. Their design features tapered inner and outer raceways. This allows them to support both radial and axial loads effectively. They perform well under heavy loads. Many industries rely on them for heavy-duty operations. The contact between the rollers and raceways maximizes load distribution. This results in improved efficiency.

In terms of installation, tapered roller bearings require precise alignment. Improper installation can lead to early failure. Routine maintenance is important to keep them functioning well. Over time, lubrication can break down. This can lead to increased friction and wear. Regular inspections are crucial for longevity.

Choosing the right bearing for your machinery is not always straightforward. Consider various factors, like load capacity and speed. Each application has its own unique needs. Learning from past experiences can guide better decisions in the future. Understanding the limitations of tapered roller bearings is part of this process.

| Feature | Description | Benefits |

|---|---|---|

| Load Capacity | Designed to support heavy loads. | Increased machinery durability and stability. |

| Alignment | Self-aligning properties help maintain proper alignment. | Reduced wear and tear on components. |

| Vibration Resistance | Effective at minimizing vibrations. | Smoother operation and longer equipment life. |

| Versatility | Suitable for various applications including automotive and industrial machinery. | Reduced need for multiple types of bearings. |

| Heat Resistance | Handles high temperatures effectively. | Enhanced performance in demanding environments. |

When selecting bearings for machinery, tapered roller bearings stand out. They excel in handling both radial and axial loads simultaneously. This is a key factor for applications requiring balanced performance under various conditions. Their conical shape allows for greater contact, resulting in efficient load distribution.

Another significant advantage is their adaptability. Tapered roller bearings can be adjusted to fit different shaft and housing dimensions. This feature can be crucial in dynamic applications. However, this flexibility may sometimes lead to installation challenges. Misalignment can result in premature wear.

Lubrication plays a crucial role in maintaining efficiency. Proper lubrication minimizes friction and overheating. Yet, maintaining optimal lubrication can be tedious. A lapse might lead to failure. Despite these complexities, the reliability of tapered roller bearings often outweighs potential downsides. They remain a worthwhile choice for robust machinery needs.

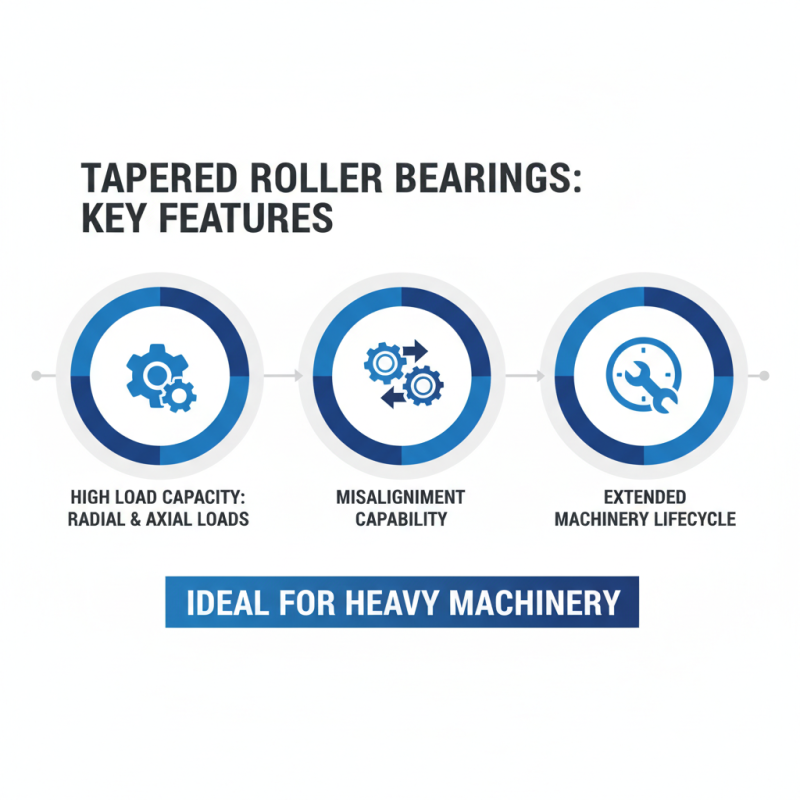

The chart above illustrates the advantages of using tapered roller bearings in machinery. It highlights their superior load capacity, durability, and lower friction compared to other bearing types, making them a favorable choice for various applications.

When selecting tapered roller bearings, several key features come into play. The load capacity is crucial. Tapered roller bearings can handle both radial and axial loads. This dual capability makes them suitable for heavy machinery. Additionally, their ability to manage misalignment is important. In dynamic environments, this feature can prolong the lifecycle of your machinery.

Another aspect to consider is the size and dimensions. Ensure you choose the correct size to fit your machinery’s specifications. Mismatches can lead to inefficiencies and increased wear. Also, consider the cage design. A well-designed cage can reduce friction and enhance performance. Not all cages are created equal. Some may require frequent maintenance or may wear out quickly.

Costs and maintenance should not be ignored. Investing in high-quality bearings can save money in the long run. However, it can be tempting to choose cheaper options. Cheaper bearings might lead to early failure, causing disruptions. Reflect on the trade-offs between price and performance; find a balance that suits your needs. The choice of oil or grease is equally critical, affecting the operational life. Make informed decisions to ensure your machinery operates efficiently.

Tapered roller bearings are vital for machinery. They provide superior load handling compared to other types. To maximize their lifespan, proper maintenance is key. According to industry reports, bearings can account for over 40% of maintenance costs in various sectors. Neglecting their upkeep can lead to premature failure.

One essential tip is lubrication. Keep bearings well-lubricated to reduce friction. Use high-quality grease to ensure smooth operation. Regularly check the lubrication levels. Over or under-lubrication can cause damage. Another tip involves periodic inspection. Look for signs of wear or contamination. Small issues can snowball into larger problems if ignored.

Monitoring operating temperatures is also crucial. If bearings run too hot, it may indicate an issue. Data suggests that operating temperatures above recommended levels can reduce bearing life significantly. Consider implementing a temperature monitoring system. This proactive approach can prevent costly repairs down the line. Regular maintenance and attention to detail are essential for tapered roller bearings.

Tapered roller bearings are essential in many industries. They support heavy loads and endure high speeds, making them popular for various machinery. In automotive applications, they help in smooth wheel rotation. Tapered roller bearings also play a significant role in conveyor systems. They ensure efficient movement of goods across many sectors.

In construction machinery, these bearings handle both radial and axial forces. They are crucial in equipment like excavators and cranes. Their ability to withstand harsh conditions is remarkable. Furthermore, in the aerospace industry, precision is critical. Tapered roller bearings help to maintain stability in aircraft mechanisms.

Despite their advantages, the choice of the right bearing can be tricky. Not every application requires the same specifications. A common mistake is choosing bearings without considering load types. This can lead to premature wear and costly downtime. Learning from these challenges can boost operational efficiency. Being diligent in selection is key for long-term success.