When embarking on a project that requires precision and reliability, the importance of selecting the right components cannot be overstated. Among these components, Angular Ball Bearings stand out due to their unique ability to support both radial and axial loads. Industry reports indicate that the global bearings market is projected to reach approximately $80 billion by 2026, with angular ball bearings being a significant segment due to their widespread application in automotive, aerospace, and industrial machinery sectors. This underscores the necessity for engineers and designers to understand the critical factors involved in choosing the best Angular Ball Bearing for their specific project needs.

The right Angular Ball Bearing can enhance equipment performance, reduce maintenance costs, and prolong service life. According to a recent study published by the International Journal of Engineering, the proper selection of bearings can lead to efficiency increases of up to 10% in mechanical systems. This highlights the technical and financial impact that informed decisions can make in various applications. By assessing load requirements, speed conditions, and environmental factors, professionals can ensure they are equipped with the optimal Angular Ball Bearing to meet their project's demands and contribute to overall operability and durability.

Angular ball bearings are a crucial component in various mechanical and engineering applications, designed to accommodate both axial and radial loads. Their unique construction allows them to handle higher speeds and precision, making them suitable for applications where angular misalignment and load direction play significant roles. Understanding their structure and functionality is essential for selecting the appropriate type for a specific project.

These bearings are widely used in industries such as automotive, aerospace, and manufacturing, where reliability and efficiency are paramount. In off-highway vehicles, for example, angular ball bearings are often utilized in wheel hubs and steering mechanisms, enabling smooth operation under heavy loads. Similarly, they find applications in high-speed machinery, such as CNC machines, where precision and durability are essential. By understanding the nature of angular ball bearings and their specific uses, engineers and designers can make informed decisions that enhance performance and longevity in their projects.

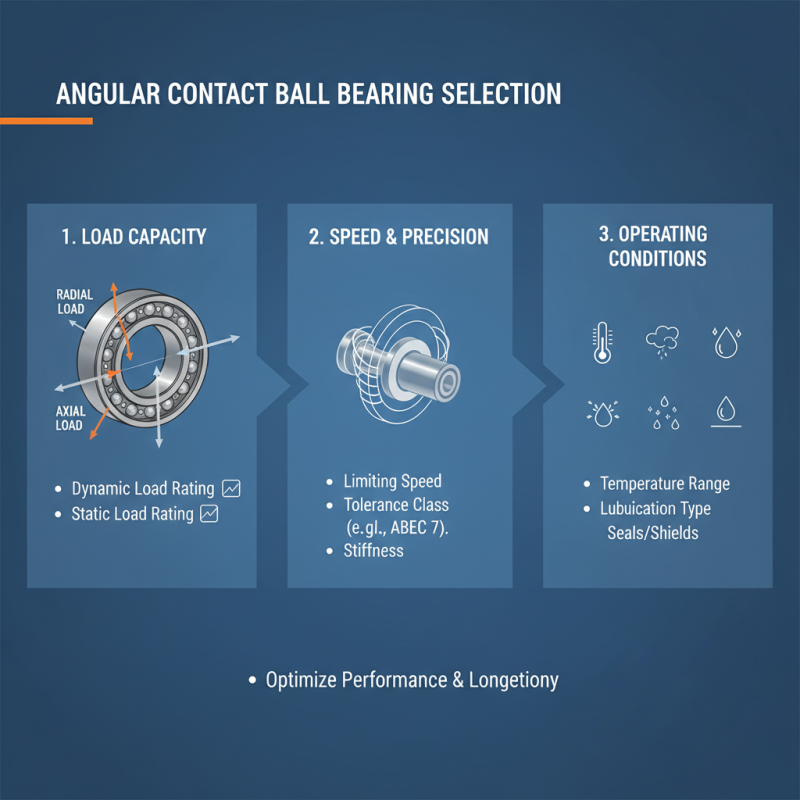

When selecting angular ball bearings for your project, several key considerations will influence your decision. First, it's essential to evaluate the load capacity of the bearings. Angular ball bearings are designed to handle both radial and axial loads. Depending on your application, understanding the dynamic and static load ratings can help ensure that the bearings will perform optimally under the anticipated conditions.

Another critical factor is the bearing's operating speed. Angular ball bearings are suitable for high-speed applications, but the maximum operating speed varies between different types. It’s important to consult the specifications to find a bearing that supports the required speed while maintaining reliability. Additionally, consider the lubrication method, as proper lubrication can significantly extend the lifespan of the bearings.

**Tips**: Always choose bearings that fit well within the tolerances of your assembly to minimize wear and tear. Furthermore, when in doubt, consult technical support or engineering experts who can provide insights into load specifications and maintenance practices tailored to your project needs. Before finalizing your choice, review the environmental conditions the bearings may encounter, such as temperature fluctuations and exposure to contaminants, to ensure optimal performance in the long run.

When selecting an angular ball bearing for your project, understanding the

material and design options available is crucial to ensure optimal performance

and durability. Angular ball bearings are typically available in various materials such as

stainless steel, chrome steel,

and ceramic.

Stainless steel bearings offer excellent corrosion resistance, making them suitable for environments that may be exposed to

moisture or chemicals. On the other hand, chrome steel is renowned for its high load capacity,

which is essential for applications involving heavy loads. Ceramic bearings, while generally more expensive, provide unique

advantages such as reduced friction and higher thermal stability, making them

ideal for high-speed operations.

The design of angular ball bearings also plays a significant role in their functionality. The angle of contact between the

balls and the raceway influences the bearing's load handling capabilities and speed ratings. A larger contact angle can

support greater axial loads but may limit speed due to increased friction. Conversely, a smaller contact angle enhances

high-speed performance but may reduce the axial load capacity. Additionally, the bearing's internal design—such as the

presence of seals or shields—can further tailor its suitability to specific applications by protecting against contaminants

or retaining lubrication. Evaluating these material and design options in relation to your project's specific requirements

is essential for achieving optimal bearing performance.

When selecting an angular ball bearing, understanding sizing and load capacity is crucial for optimal performance in your project. Angular ball bearings are designed to accommodate both radial and axial loads, making them essential in applications where high precision and reliability are paramount. According to a recent market report by the International Journal of Engineering and Technology, the correct sizing of these bearings not only contributes to the mechanical efficiency of the machinery but also affects the overall lifespan of the components. Thus, selecting the proper dimensions—inner diameter, outer diameter, and thickness—ensures that the bearing will fit within the designated housing and handle the specific load requirements effectively.

Load capacity is another significant factor in angular ball bearing selection. These bearings are categorized based on their load ratings, determined by factors such as material composition and design layout. Typically, the dynamic load rating, which characterizes the bearing’s ability to handle loads during operation, is a focal point. Research indicates that using bearings with appropriate load ratings can lead to a performance increase of up to 30% in mechanical systems. Engineers often employ tools like the SKF Bearing Select software to calculate the necessary load capacities, ensuring their bearings can withstand peak application loads without compromising functionality. Consequently, a thorough understanding of both sizing and load capacity is vital for ensuring that the chosen angular ball bearing meets the demands of the project while promoting longevity and performance.

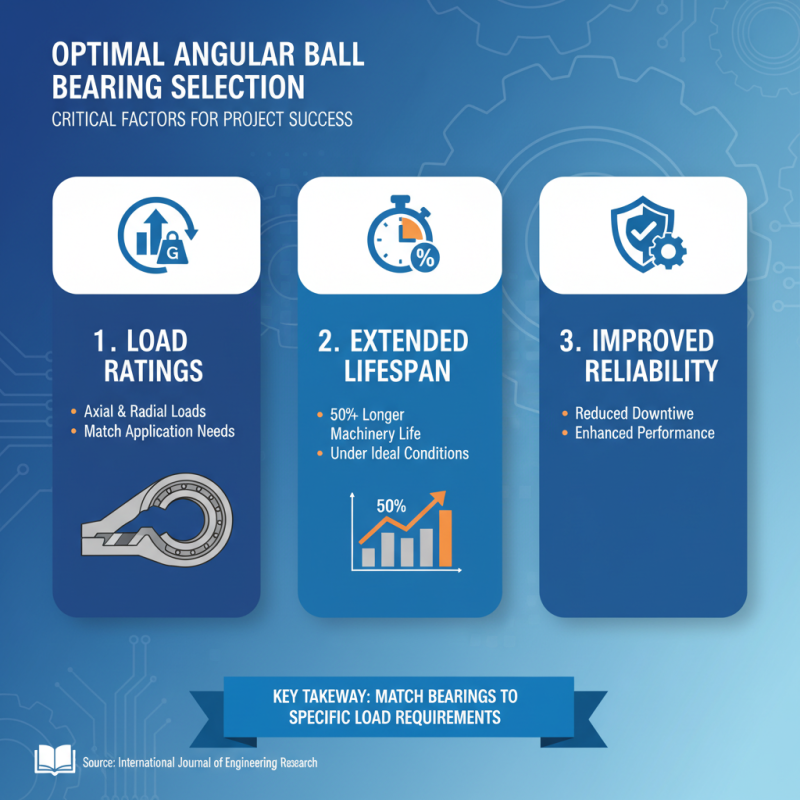

When selecting the best angular ball bearing for project needs, ensuring optimal performance hinges on a few critical factors. First, it's essential to consider the load ratings of the bearings, which reflect their capacity to support axial and radial loads. According to the International Journal of Engineering Research, properly rated bearings can extend the lifespan of machinery by 50% or more when operating under ideal conditions. Therefore, using bearings that match the specific load requirements of your application can significantly improve performance and reliability.

Material selection plays a vital role in the performance of angular ball bearings. High-grade steel or ceramic materials can withstand greater stress and resist wear over time. A study published in the Journal of Mechanical Engineering highlights that bearings made from advanced composites can achieve a 30% reduction in friction, leading to energy efficiency gains of similar proportions. This is crucial for projects where energy consumption and operational costs are of high concern. Additionally, ensuring correct lubrication to minimize friction and heat generation further enhances the longevity and effectiveness of the bearings, reinforcing the need for thorough technical assessments during the selection process.