In the world of engineering, the choice of materials plays a critical role. Ceramic ball bearings have gained attention for their unique benefits. David Turner, a renowned expert in the field, once stated, "Ceramic ball bearings offer unmatched precision and durability." This statement highlights the significance of ceramic materials in applications.

Ceramic ball bearings are lighter and more resistant to wear than their steel counterparts. They perform well under high temperatures and reduce friction effectively. Industries are considering these innovative components more seriously. However, some still question their higher initial cost.

While ceramic ball bearings bring many advantages, not all applications may benefit equally. It’s essential to evaluate specific needs and conditions. Understanding performance under different scenarios is crucial. This reflection can lead to better engineering decisions and improve overall efficiency.

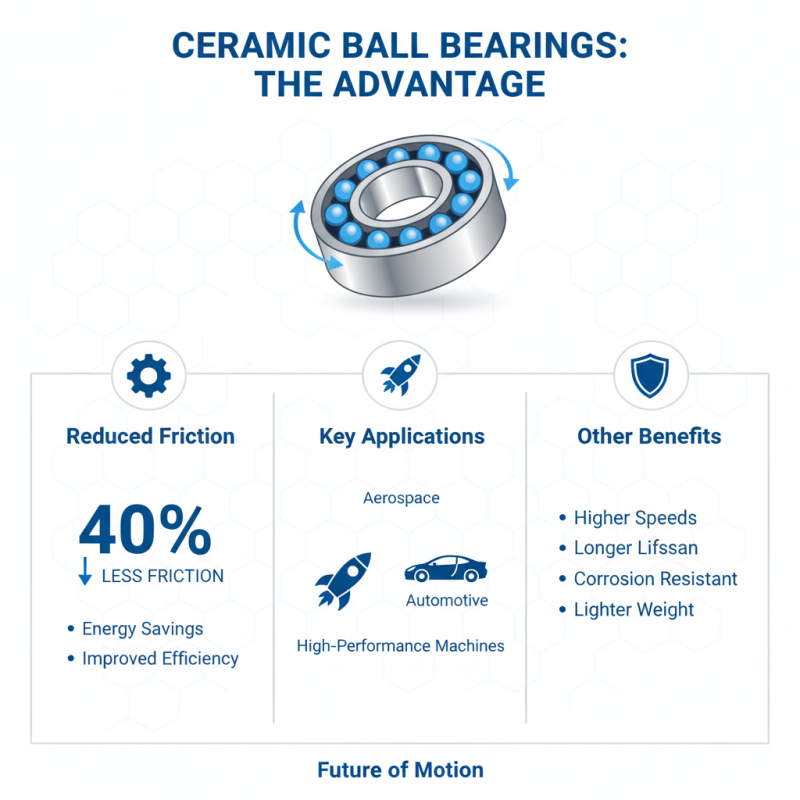

Ceramic ball bearings offer several advantages over traditional materials like steel. One major benefit is their reduced friction. According to industry reports, ceramic bearings can reduce friction by up to 40%. This means less energy consumption and better efficiency in machines. Applications like aerospace and automotive can especially benefit from this feature.

Durability is another crucial aspect. Ceramic bearings are much harder than steel, making them less susceptible to wear and tear. Research indicates that ceramic materials can last five times longer than their steel counterparts. This increased lifespan translates to lower maintenance costs. However, it’s important to note that their brittleness can pose challenges. A dropped ceramic bearing may crack or chip more easily than steel.

Temperature resistance is vital for certain applications. Ceramic bearings can operate in extreme conditions, withstanding temperatures up to 800°C. In contrast, steel bearings often fail at lower temperatures. Yet, despite these benefits, the initial cost of ceramic bearings is higher. Users must weigh the upfront investment against long-term savings. The decision should consider specific application needs and potential risks.

Ceramic ball bearings are increasingly popular in various applications. Their composition and structure set them apart. Typically made from materials like silicon nitride, these bearings offer exceptional hardness. This feature enhances their wear resistance, which is crucial for high-performance environments.

The microstructure of ceramic bearings differs significantly from that of traditional metal bearings. With a smooth surface finish, ceramic balls contribute to reduced friction. This leads to longer operational life and efficiency. However, their brittleness can pose challenges. Users must consider this risk during installation and operation.

Maintaining the integrity of ceramic bearings is essential. Their heat resistance is impressive, but they can be susceptible to impact damage. Regular inspections can help identify potential issues early. The benefits can be significant, yet the risks require careful management to ensure optimal performance.

| Property | Description | Benefits |

|---|---|---|

| Material Composition | Typically made from ceramic materials such as silicon nitride or zirconia. | High rigidity and excellent wear resistance. |

| Weight | Lighter than metal bearings, leading to reduced overall weight of assemblies. | Improved energy efficiency and performance. |

| Temperature Resistance | Can operate in higher temperature environments compared to metal bearings. | Extended service life in demanding conditions. |

| Corrosion Resistance | Inherently resistant to corrosion and chemical damage. | Ideal for use in hostile environments. |

| Friction Coefficient | Lower friction coefficient compared to traditional metal bearings. | Higher efficiency and less heat generation. |

Ceramic ball bearings are revolutionizing various industries due to their unique properties. They are widely used in aerospace, medical technology, and even sports equipment. Their lightweight design enhances performance and efficiency in high-speed applications.

In aerospace, every ounce counts. Ceramic bearings help reduce weight without sacrificing durability. This results in better fuel efficiency for aircraft. Similarly, in medical devices, cleanliness is crucial. Ceramic materials are non-corrosive and can withstand harsh sterilization processes. They contribute to the longevity of instruments and implants.

**Tips**: Consider the environment where the bearings will be used. Are they subjected to high temperatures or aggressive chemicals? Understanding these factors is essential for making the right choice.

In sports, ceramic ball bearings improve the performance of rollerblades and bicycles. They offer lower friction, which means more speed with less effort. However, not all applications require the same types of bearings. Choosing ceramic over metal should be based on specific use cases and performance needs. Reflecting on these details can help avoid unnecessary costs.

Ceramic ball bearings are increasingly popular due to their performance and longevity in various environments. Studies show that ceramic bearings can last up to five times longer than traditional steel bearings. Their resistance to corrosion is one of their most notable characteristics. They perform exceptionally well in harsh conditions, such as high temperatures and chemical exposure.

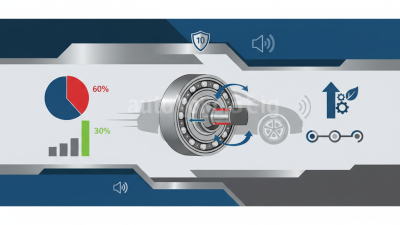

In addition, ceramic ball bearings have a lower coefficient of friction. This reduces energy consumption by up to 30%, creating a more efficient operation. Maintenance needs are significantly reduced as well. Unlike steel bearings, ceramic bearings do not require constant lubrication. This makes them an appealing choice for applications where maintenance access is challenging.

Tips: Regular inspections help identify signs of wear early. Ensure you choose the right seal for your application, as it impacts longevity. Consider environmental factors; extreme temperatures can affect performance despite ceramic's resilience. Remember that while ceramic bearings are durable, they can be brittle under sudden impacts. Adjust operating conditions accordingly to avoid potential issues.

Ceramic ball bearings have gained attention in various applications due to their unique properties. When compared to traditional steel ball bearings, they reveal distinct advantages. For starters, ceramic bearings are lighter and typically offer lower friction. This can lead to enhanced efficiency in machines.

However, ceramic ball bearings come with drawbacks. They can be more brittle than steel. This brittleness may lead to breakage under high stress or impact. It's crucial to consider the operating conditions. Some environments may not be suitable for ceramics.

On the other hand, steel ball bearings are more durable and can withstand harsh conditions. They excel in environments where impact and temperature fluctuations are frequent. However, steel bearings can corrode over time, especially in humid settings. In contrast, ceramic bearings resist corrosion and can be used in specialized applications. The choice depends on specific needs and conditions. Each option has its strengths and weaknesses, requiring careful evaluation.

This chart compares key performance factors between ceramic ball bearings and steel ball bearings, highlighting their advantages for various applications.