Choosing the right cylindrical roller bearing is crucial for machinery performance. The global bearings market is expected to reach $100 billion by 2026, according to a recent report by Research and Markets. This highlights the significance of selecting the most appropriate cylindrical roller bearing for diverse applications.

Expert John Smith, an industry authority, states, "Choosing the right bearing can drastically affect machinery lifespan." It's not just about size and load capacity. Factors like speed, environment, and lubrication play crucial roles too. Many users overlook these details, leading to premature failures. The consequences can be significant, impacting uptime and costs.

In practice, a cylindrical roller bearing must align with specific operational needs. A mismatch can lead to inefficiencies. For example, using a bearing in a high-speed application rated for low speeds can cause overheating. Understanding the operational environment and requirements is essential. Each application demands a tailored approach, making knowledge and careful assessment paramount.

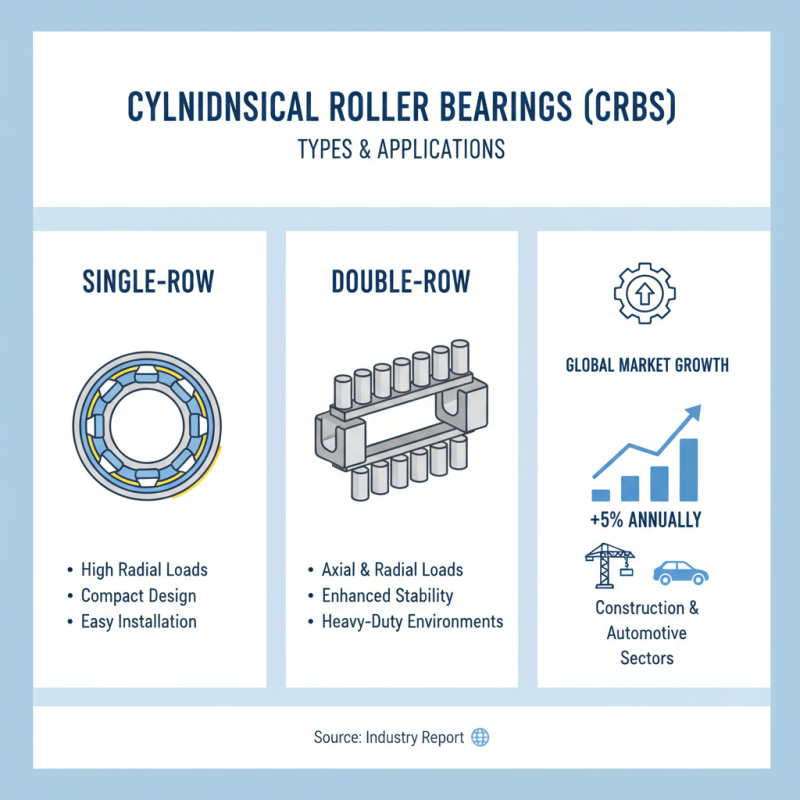

Cylindrical roller bearings (CRBs) come in various types, each designed to meet specific needs. The most common configurations are single-row, double-row, and multi-row bearings. Single-row bearings are ideal for applications with high radial loads. They are compact and easy to install. In contrast, double-row bearings can handle axial loads better, offering more stability in heavy-duty environments. According to a recent industry report, the global market for cylindrical roller bearings is expected to grow by 5% annually, driven by increased demand in construction and automotive sectors.

Selecting the right specification is critical. Consider the internal clearance, tolerance, and lubrication type. High precision requires tight tolerances. For instance, a tolerance of P5 is appropriate for high-speed applications. It’s essential to analyze the expected operating conditions. The wrong choice can lead to premature failure. Inadequate lubrication can cause overheating, resulting in lower efficiency. Additionally, be aware of the load ratings. Misalignment in load distribution can affect bearing life dramatically. Many engineers overlook these details and later face significant downtime.

Ultimately, understanding these nuances can prevent costly mistakes. A mismatch in bearing type or spec can lead to subpar performance. Many users do not regularly assess their choices, impacting reliability. Challenges are inevitable in the selection process. Each bearing type has its unique features and limitations. Knowing how to weigh these factors ensures better performance and longevity.

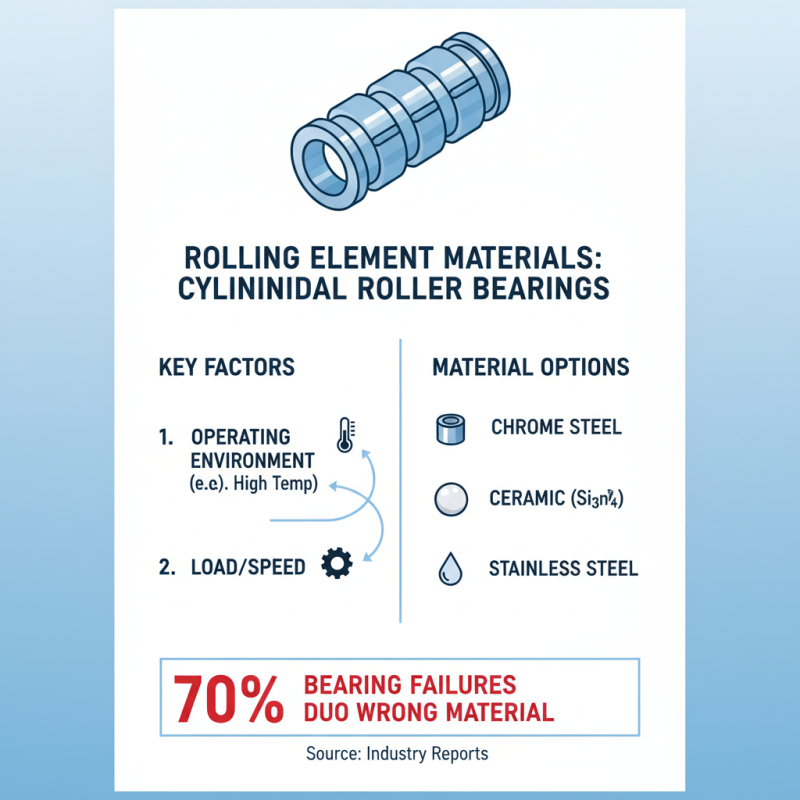

When selecting the right rolling element material for cylindrical roller bearings, a few key factors come into play. One crucial consideration is the operating environment. For instance, if high temperatures are expected, materials like chrome steel or ceramic may be suitable. According to industry reports, up to 70% of bearing failures are linked to inadequate material choice.

Additionally, load-bearing capacity affects material selection. For heavy loads, hardened steels are often preferred. Notably, these materials can withstand significant stress and prevent premature failure. However, they may not perform well in corrosive environments.

Tip: Always consider lubrication compatibility with your chosen material. This can significantly impact the lifetime of your bearings.

If your application involves high-speed operations, ceramic materials can offer advantages. They are lighter and can handle high RPMs effectively. Nevertheless, they may be more brittle compared to steel counterparts. Some users report higher costs as a drawback. Evaluate the trade-offs carefully.

Tip: Conduct a thorough analysis of your application’s requirements before making a decision. This will help ensure that you choose the most fitting material. Balancing performance, cost, and longevity is essential for achieving optimal results.

When selecting a cylindrical roller bearing, understanding load ratings is crucial. Load ratings indicate how much weight a bearing can handle. These ratings are essential for predicting the bearing's performance and lifespan. An improper load rating can lead to premature failure. Lower rated bearings may wear out quickly under high loads. This can be costly in terms of repairs and downtime.

Different applications require varying load ratings. High-speed machinery may need bearings designed for specific dynamic loads. On the other hand, stationary applications might prioritize static load ratings. It's essential to match the load requirement with the right rating. Miscalculating can lead to significant problems. Too much load causes overheating and potential breakdowns. Therefore, it's vital to closely evaluate your application needs. Sometimes, it may require consulting with a specialist. Relying solely on standard ratings might not suffice.

Remember, the right choice is often not straightforward. Each environment presents unique challenges. Overlooking factors like lubrication and installation can compromise performance. Don't underestimate the importance of these elements. They significantly impact how well a bearing works under load. Taking time to reflect on these details aids in making the right decision. Balancing load expectations with actual usage is critical for optimal performance.

Cylindrical roller bearings have various applications across multiple industries. They are commonly used in automotive, aerospace, and manufacturing sectors. These bearings can handle heavy radial loads. Their design enables efficient performance under high-speed conditions.

In automotive applications, cylindrical roller bearings support gear systems and transmissions. They often face severe conditions, including heat and vibration. In such scenarios, selecting the right size and load capacity is critical. For aerospace, these bearings ensure reliability in the most demanding environments. They must meet strict industry standards for safety and performance.

Understanding the specific requirements of your application is essential. Factors like load ratings and operating temperatures must be considered. Some users overlook these details, leading to premature failures. It’s important to balance performance and cost. Choosing based solely on price can result in long-term issues. Reflecting on your specific needs can guide you to the right choice.

| Bearing Type | Applications | Load Capacity (kN) | Speed Rating (rpm) | Industry Standards |

|---|---|---|---|---|

| Single Row | Generators, Motor drives | 30 - 400 | 2000 - 5000 | ISO 492 |

| Double Row | Heavy machinery, Wind turbines | 50 - 1000 | 1500 - 3000 | DIN 5412 |

| Cage Guided | Automotive, Robotics | 20 - 300 | 2500 - 6000 | JIS B 1501 |

| Full Complement | Mining, Construction | 100 - 1200 | 1000 - 2000 | AASHTO M 203 |

Maintaining cylindrical roller bearings is crucial for their longevity and reliability. Regular maintenance helps to identify potential issues before they escalate. One key aspect is lubrication. Proper lubrication reduces friction and heat. Ensure that you use the right type and amount of lubricant as specified in the bearing's guidelines.

Tip: Check lubrication levels frequently. It's easy to overlook this step, yet it's vital for performance.

Another essential consideration is cleanliness. Contaminants can cause premature wear. Implement a cleaning schedule and use appropriate tools to prevent damage. Inspect bearings regularly for signs of wear or damage, as early detection can save costs.

Tip: Use protective covers or seals. They can significantly reduce the risk of contamination. Remember, a small investment in protection can save you from larger repairs later.

Finally, monitor operating conditions. Vibration and temperature can indicate trouble brewing. If something seems off, don't ignore it. Addressing these issues promptly can prolong the life of your bearings. Unattended problems can lead to more significant failures down the line.