Choosing the right V Groove Ball Bearing can be challenging. Different applications demand different specifications. John Smith, a renowned expert in the bearing industry, once said, "Selecting the right V Groove Ball Bearing is crucial for performance." This quote emphasizes the importance of making an informed choice.

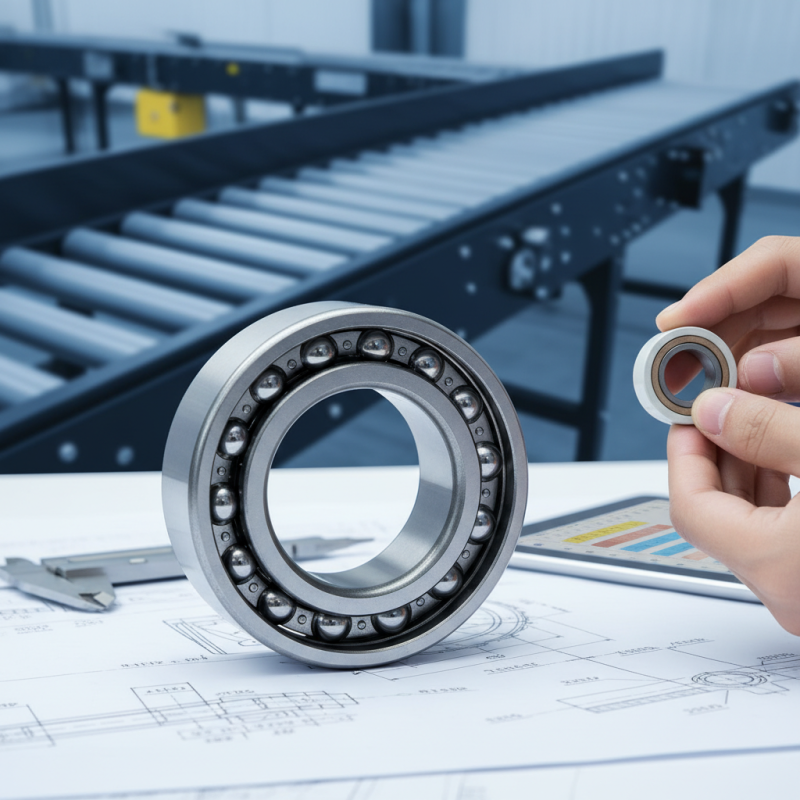

V Groove Ball Bearings are often used in conveyor systems. They ensure smooth movement and reduce wear. However, not all bearings are created equal. Factors such as load capacity and material type matter significantly. Understanding these can lead to better performance and durability.

Many buyers overlook critical details. They focus on price rather than quality. This can lead to costly maintenance issues later on. It’s essential to consider both immediate needs and long-term goals. Finding the right balance can enhance efficiency and reliability in operations.

V groove ball bearings are crucial for various applications, especially in systems requiring smooth linear movement. They play a significant role in conveyor systems, robotics, and sliding gates. According to industry reports, over 30% of manufacturing processes depend on reliable bearings. The design of V groove bearings allows for precise tracking and stability, making them ideal for machinery that needs to operate continuously.

Understanding the functionality of these bearings is essential. They provide low friction, which can enhance energy efficiency in machinery. Reports indicate that improved bearing efficiency can lead to a 20% reduction in energy costs. However, not all V groove bearings are created equal. Material selection and precision in manufacturing greatly impact performance. It's vital to assess the load capacity and speed requirements. Sometimes, users make the mistake of choosing based on price alone, which may lead to early failure.

Installation plays a pivotal role in the overall effectiveness of V groove bearings. A misalignment can cause excessive wear and reduce lifespan. Many users overlook the importance of proper mounting and maintenance. Regular inspections can prevent unexpected breakdowns. In conclusion, being informed about the functionalities of V groove ball bearings can significantly improve operational efficiency and durability in various applications.

This chart compares three different types of V Groove Ball Bearings based on their load capacity, speed rating, temperature range, and noise level. Understanding these parameters can help in selecting the appropriate bearing type for specific applications.

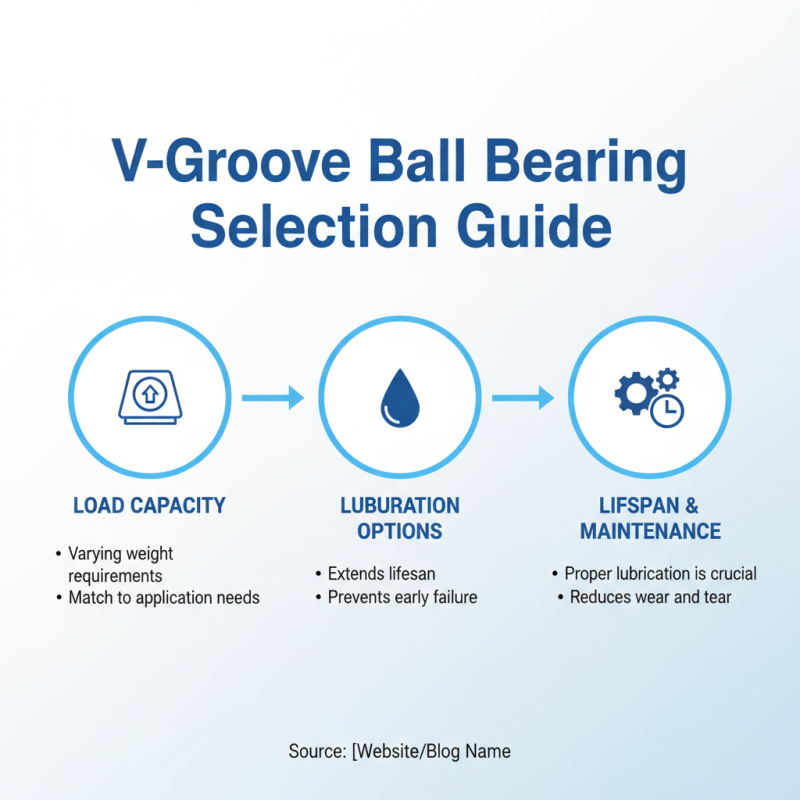

When selecting V groove ball bearings, several key factors come into play. Consider the load capacity. Different applications have varying weight requirements. A lightweight application may not need a heavy-duty bearing. Look for lubrication options too. Proper lubrication extends the bearing's life. An unsuitable lubricant can lead to early failure.

Tip: Always check the operating temperature range of the bearing. If your environment is too hot or too cold, it could impact performance.

Next, think about the material. Steel is common, but plastic offers corrosion resistance. If your application involves moisture, a plastic option might be better. However, note that plastic may not handle heavy loads as steel can.

Finally, precision matters. Depending on your project's requirements, you might need high precision or standard precision. Poor quality bearings can lead to misalignment and increased wear. Reflect on what your project truly needs.

Tip: Order a few samples to test before making a bulk purchase. This can reveal any flaws early.

When selecting a V groove ball bearing, material choice plays a vital role. Common materials include stainless steel, carbon steel, and plastic. Each material has unique strengths and weaknesses, influencing performance and durability. Stainless steel offers excellent corrosion resistance, making it ideal for wet environments. However, its cost can be higher than carbon steel, which is more affordable but may rust when exposed to moisture.

Plastic bearings are lightweight and resistant to certain chemicals. They are often quieter and work well in specific conditions. Yet, they may not handle heavy loads effectively. Choosing the right material depends on your specific needs. If you require high precision, stainless steel might be preferable. However, heavy loading applications may benefit from robust carbon steel.

Sometimes, the choice isn't clear-cut. For instance, a project could seem better suited for plastic until load ratings reveal limitations. Reflecting on these decisions is crucial. Each material has trade-offs that can impact the longevity and efficiency of your setup. Assessing your unique situation will guide you to the best option for your V groove ball bearing.

V groove ball bearings find extensive applications across various industries. Designed for specific functionalities, their configurations cater to different operational needs. Industries such as manufacturing, construction, and automation rely on them for smooth operation. According to a recent market report, the demand for V groove ball bearings is expected to reach $2.5 billion by 2025. This growth indicates their increasing importance in machinery and equipment.

In manufacturing, these bearings enhance the performance of conveyor systems. They support heavy loads while maintaining low friction. Construction machinery also benefits from their durability and efficiency. The bearings help in reducing maintenance costs. However, selecting the wrong type can lead to excessive wear and tear.

Automation systems utilize V groove ball bearings for precise movements. High-speed applications require accurate performance. The bearings facilitate seamless transitions in automated setups. However, overloading these components may jeopardize their efficiency. Manufacturers must ensure proper alignment and installation. Data shows that improper handling reduces the lifespan of these bearings by up to 30%. Understanding the specificities of your application is crucial.

Choosing the right V groove ball bearing is essential, but maintenance is equally important. Regular care can significantly increase their lifespan. First, ensure that the bearings are kept clean. Dust and debris can disrupt their operation. Use a soft cloth to wipe them down regularly. A gentle brush can help remove any stubborn particles.

Lubrication is another key aspect. Applying the right lubricant can greatly reduce friction. However, over-lubricating can attract dirt and lead to failures. It's vital to find a balance. Check the manufacturer’s guidelines for suitable lubricants. Monitor the bearings for any unusual sounds. Grinding or squeaking noises are often signs of wear or damage.

Temperature control is useful too. High heat can deteriorate bearings faster than expected. If they are operating in a hot environment, consider cooling solutions. Even if all guidelines are followed, issues may still arise. Regular inspection is crucial. It helps identify potential problems before they become severe. Reflecting on past maintenance can guide future actions.

| Parameter | Details |

|---|---|

| Load Capacity | Radial and axial load specifications based on application requirements. |

| Material | Common materials include stainless steel, chrome steel, and ceramic. |

| Bearing Size | Dimensions must match the application’s mounting requirements. |

| Speed Rating | Determine the maximum speed for safe operation. |

| Lubrication Type | Grease, oil, or sealed types depending on usage and environment. |

| Environmental Considerations | Consider humidity, temperature, and exposure to contaminants. |

| Maintenance Needs | Regular inspections and lubrication schedules to prolong lifespan. |