Choosing the right Bearing Roller Tapered is crucial for optimal machinery performance. These components play a vital role in reducing friction and handling loads effectively. According to a recent industry report by the Global Bearings Market, over 30% of equipment failures stem from improper bearing selection. This highlights the significance of understanding the unique specifications of Bearing Roller Tapered.

Expert John Smith, a leading authority in bearing technology, states, "Selecting the proper bearing type can drastically improve machine longevity and efficiency." His insights emphasize the need for careful consideration of load capacities, speed ratings, and environmental factors.

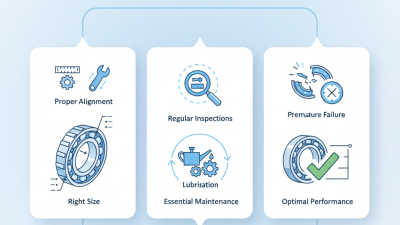

While many overlook these aspects, attention to detail is essential. Factors like lubrication methods and alignment also impact the performance of Bearing Roller Tapered. It's important to reflect on common misconceptions that could lead to misselection. A wrong choice can lead to higher maintenance costs and decreased productivity in the long run.

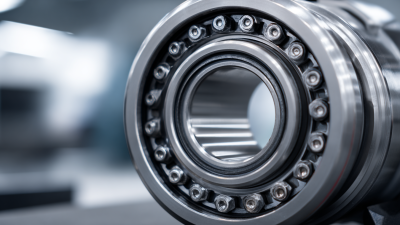

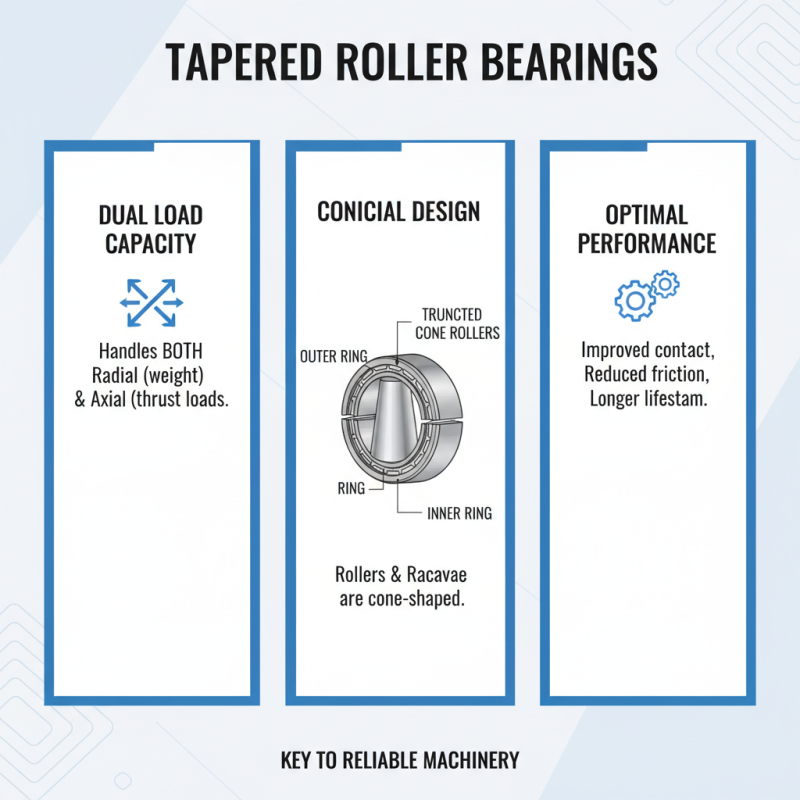

Tapered roller bearings are crucial in many mechanical applications. They are designed to handle both radial and axial loads. Understanding their design is key for optimal performance. The rolling elements are shaped like truncated cones. This shape allows for better contact with the raceway, reducing friction.

When selecting tapered roller bearings, consider several factors. Load capacity is one of the most important. You need to assess the environment too. High temperatures can affect the bearing’s life. Sometimes, a seemingly perfect choice may not perform well under stress. Regular maintenance is vital. It helps to identify wear and potential failures early.

Visualizing the application can help in the selection process. Picture the components working together. The bearings must align correctly. Misalignment can lead to increased wear and failure. Often, engineers overlook this aspect. Paying attention to dimensions is essential. A small mistake can lead to significant issues later. These factors highlight the importance of careful selection for reliable performance.

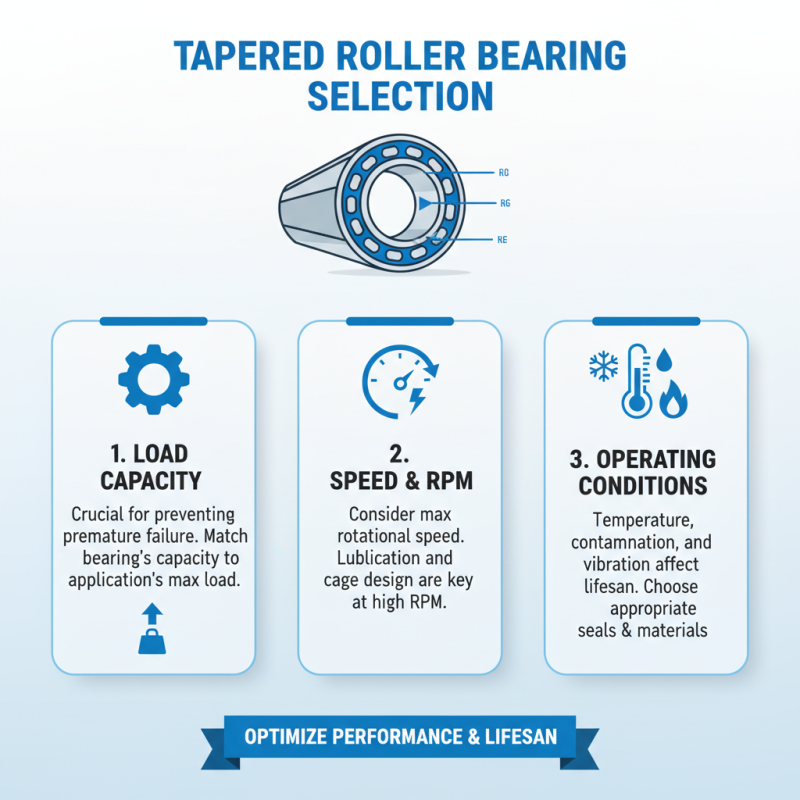

When selecting tapered roller bearings, several key factors come into play. The load capacity is crucial. Knowing the maximum load your application will face helps in choosing the right bearing. If the load exceeds the bearing's capacity, it can lead to premature failure.

Another important factor is the operating speed. Tapered roller bearings have speed limits defined by design and material. Exceeding this limit causes overheating. Overheating leads to lubrication failure and increased wear. Understanding the balance between load and speed is essential for optimal performance.

Tips: Always consult technical specifications before making any choices. Assess the environment too. Temperature fluctuations, dust, and moisture can affect performance. Regular maintenance is vital. Over time, even the best bearings may wear down or lose lubrication. Addressing these issues can extend bearing life. Choosing tapered roller bearings demands attention and understanding. Reflecting on each factor can help in making informed decisions.

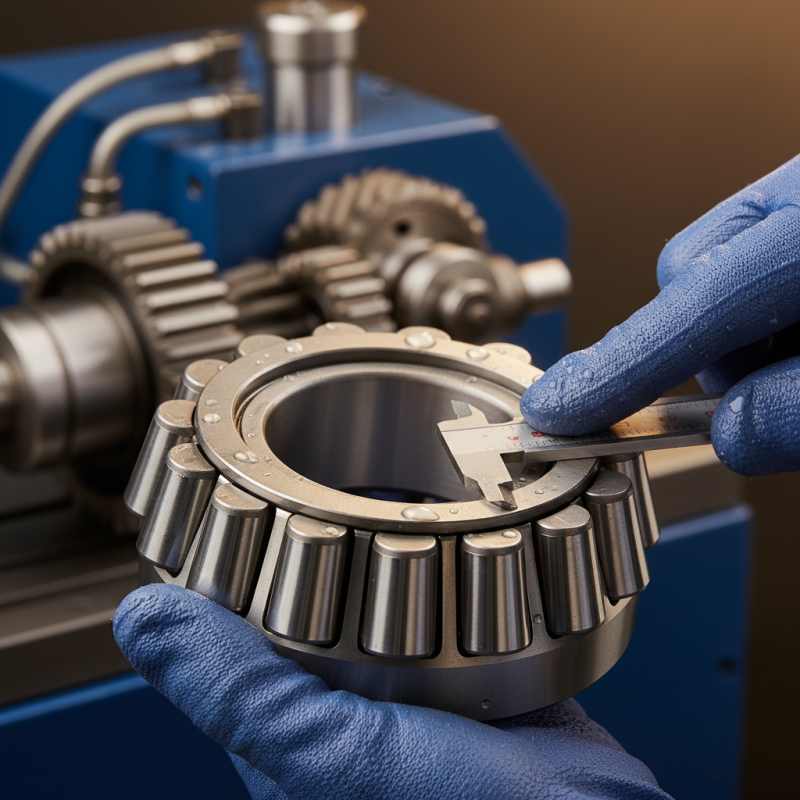

Choosing the right size and load capacity for tapered roller bearings is crucial. These components support heavy loads and impact performance. If you select the wrong size, it can lead to rolling fatigue or premature failure. It's essential to assess the application before making a decision.

Understanding the load capacity is key. Each bearing has a specified load rating. This rating tells you how much weight it can handle. However, many overlook the importance of dynamic and static load ratings. It's also vital to consider factors like operating speed and temperature impacts. Ignoring these could result in unexpected breakdowns.

Don’t rush this process. Mistakes in sizing can be costly. Conducting thorough calculations will help. It may take extra time, but it ensures reliability. Ultimately, careful consideration here can save resources down the line. Reflect on all variables to make the best choice.

This chart illustrates the relationship between the size of tapered roller bearings and their corresponding load capacity. Selecting the right size and load capacity is vital for optimal performance in various applications.

When selecting tapered roller bearings, the choice of material is crucial for durability. High-quality steel is often preferred. According to a report by the American Bearing Manufacturers Association, materials can influence bearing fatigue life significantly. Subpar materials can lead to premature failure, costing both time and resources.

Ceramic materials have gained traction in specialized applications. They offer lower friction and higher wear resistance. However, they can be brittle. Proper testing and evaluation are necessary. Industry data reveals that bearings made with advanced ceramics can last 30% longer than conventional steel options. Still, their cost can be a barrier for some manufacturers.

Another consideration is the heat treatment process. Proper hardening improves the fatigue strength of bearings. Studies show that bearings subjected to optimal heat treatment can exhibit a 40% increase in load-carrying capacity. Yet, this process requires careful monitoring to avoid warping. Choosing the right material and processes involves a trade-off between performance and budget constraints.

Proper installation and maintenance of tapered roller bearings are crucial for maximizing performance. According to industry reports, around 30% of bearing failures are linked to improper installation. Misalignment, dirt, and insufficient lubrication often cause damage. Ensure that your working environment is clean. A tidy workspace minimizes contamination and extends bearing life.

Regular checks are vital. It’s recommended to inspect the bearings every few months. Look for signs of wear such as discoloration or unusual noise. Simple tools can help detect issues early. For lubrication, follow the manufacturer’s guidelines closely. Over-lubrication can be as harmful as under-lubrication. The correct grease enhances efficiency and reduces friction.

Staying educated on the latest practices is important. Training sessions can help in understanding the nuances of bearing maintenance. Reports indicate that companies investing in employee training reduce downtime by 25%. Awareness and proactive measures ensure optimal functionality, but challenges like resource limitations can hinder regular maintenance checks. Balancing these aspects is key to maximizing performance and extending bearing lifespan.