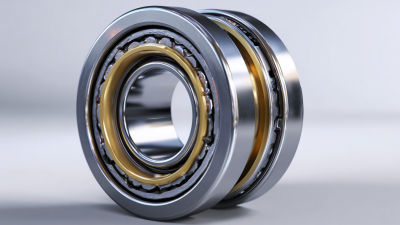

Choosing the right Bearing Roller Cylindrical is crucial for your application. With a variety of options available, it can be overwhelming. Each choice impacts performance and efficiency. Understanding the basics is essential.

Consider the load capacity of the Bearing Roller Cylindrical. Too small, and it will fail; too large, and it adds unnecessary costs. Look closely at the dimensions as well. The fit in your machinery should be precise. Don't overlook this detail.

Certain environments demand specific materials. For example, corrosion resistance is vital in harsh conditions. Evaluate the temperature range as well. These factors are often underestimated. Mistakes here can lead to costly downtime. The more informed you are, the better your choice will be.

When selecting cylindrical roller bearings, several factors must be considered. One key aspect is load capacity. Data from the International Organization for Standardization (ISO) indicates that cylindrical roller bearings can support high radial loads. However, not all designs are optimized for the same applications. Knowing your load requirements is essential.

Another important factor is speed. High rotational speeds may impact bearing performance. According to a report by the American Bearing Manufacturers Association (ABMA), some cylindrical roller bearings can operate effectively at speeds up to 20,000 RPM. Yet, thermal limitations may arise, leading to premature failure. Engineers need to ensure that they choose bearings suited for the expected speeds of their machinery.

Lubrication is also crucial. Effective lubrication minimizes wear and prolongs bearing life. A study by the National Lubricating Grease Institute (NLGI) reveals that inadequate lubrication can lead to a 40% reduction in bearing lifespan. It’s a common oversight. Choosing the right lubricant type and quantity can be challenging but can greatly affect performance. Balancing these factors can significantly impact the efficiency and reliability of your application.

When selecting bearing roller cylindrical designs, understanding load ratings is crucial. Load ratings indicate how much weight the bearings can support. They are not always straightforward, though. It's easy to assume that higher ratings equal better performance. But the application specifics often change this perspective.

Each application has unique demands. Some may require higher dynamic load capacity, while others may focus on static loads. It's vital to determine what kind of load the bearing will face. For instance, a machine operating under heavy vibrations might not align with a bearing designed for steady loads. Knowing the difference can prevent costly breakdowns.

Consider the environment too. Temperature fluctuations and exposure to contaminants can alter load capacity. Bearings might perform well in controlled conditions but fail in harsher settings. It's not always easy to predict these outcomes. The right choice often requires careful thought and experimentation, ensuring the best fit for your needs.

When considering bearing roller cylindrical options, material choice plays a crucial role. Different materials can significantly affect performance. Common materials include steel, aluminum, and plastic. Each type has unique properties that influence durability and friction. For instance, steel bearings are known for their strength and longevity. But they can be heavier and more expensive.

On the other hand, aluminum offers a lighter alternative. It has good strength-to-weight ratio but may wear faster under heavy loads. Plastic bearings are often overlooked but have advantages like corrosion resistance and low noise. They are suitable for specific applications, especially where moisture is a concern.

Choosing a material requires reflection on operating conditions. Consider temperature, load, and environment. A lightweight option may seem attractive, but it might not always be the best choice. Each application has its nuances that demand careful evaluation. The wrong choice can lead to premature failure or increased maintenance. It is essential to weigh the positives against potential downsides.

| Material | Corrosion Resistance | Load Capacity | Temperature Resistance | Cost |

|---|---|---|---|---|

| Carbon Steel | Low | High | Moderate | Low |

| Stainless Steel | High | Moderate | High | Moderate |

| Ceramic | Very High | Very High | Very High | High |

| Polymer | Moderate | Low | Low | Low |

When selecting cylindrical roller bearings for your application, understanding key dimensions and tolerances is crucial. These physical specifications directly affect the bearing’s performance. Focus on parameters like outer diameter, inner diameter, and width. Each dimension must suit your equipment perfectly. Improper sizing can lead to friction and premature failure.

It's essential to pay attention to tolerances, as these determine the fit. A tight tolerance can enhance stability but may also lead to excessive wear under load. On the other hand, loose fits can result in vibration. An ideal balance is necessary for longevity and efficiency.

**Tips:** Measure your shaft and housing accurately before making a selection. Take time to understand the load conditions your bearings will face. Regularly assess the bearing’s performance to identify potential issues early. Be aware that even minor misalignments can cause significant complications in operation.

When selecting bearing roller cylindrical for a specific application, evaluating operating conditions is crucial. Key factors include temperature, speed, and environment. These elements influence the performance and lifespan of your bearings.

Temperature plays a significant role. High temperatures can degrade lubrication, impacting performance. Low temperatures might cause materials to become brittle. Always consider the temperature range your application will experience.

Tip: Regularly check the ambient temperature in your working environment. This simple step can prevent unexpected failures.

Speed is another critical factor. High-speed operations generate heat and require bearings that can handle the strain. On the other hand, low-speed applications may allow for different bearing materials.

Tip: Evaluate the maximum speed your application reaches. This can help in choosing bearings that will endure the demands.

The environment also matters. Dusty, wet, or corrosive environments can affect bearing performance. Specific seals and materials can enhance protection against harsh conditions.

Tip: Think about the cleanliness of your application area. A clean environment can extend bearing life significantly.

Choosing the right bearing requires deep consideration of these conditions. Every application is unique and might require adjustments in the selection process. It’s essential to reflect and reassess your needs regularly.