When selecting components for your machinery, the choice of bearings is crucial. Among them, Deep Groove Ball Bearings stand out due to their versatility. Expert Alex Turner, a specialist in bearing technology, states, "Deep Groove Ball Bearings are the backbone of many industrial applications." This highlights their importance in modern engineering.

Choosing the right Deep Groove Ball Bearing requires understanding your specific needs. Factors such as load capacity, speed, and operating conditions play a vital role. It can be overwhelming. Many overlook these details and make hasty choices, leading to inefficiencies or even failures.

Pay attention to bearing dimensions and material quality. The right Deep Groove Ball Bearing can enhance machinery performance, while the wrong one can lead to costly delays. It's essential to invest time in research and consultation before making a decision. Each project is unique, and a one-size-fits-all approach rarely succeeds.

Deep groove ball bearings are widely used in various applications due to their versatility. They can handle both radial and axial loads, making them suitable for use in electric motors, automotive components, and industrial machinery. These bearings feature deep raceway grooves that provide greater contact areas between the balls and the races. This design allows for smoother operation and lower friction, which is vital in high-speed applications.

When considering deep groove ball bearings, it's important to assess the project requirements. Factors such as load capacity, speed, and environmental conditions significantly influence the choice. Selecting the wrong type can lead to premature failure or inefficiencies. For instance, using bearings with insufficient load ratings can result in overheating or wear. Yet, it’s easy to overlook these details during the planning stage, which can lead to costly mistakes.

In applications where precise alignment is crucial, deep groove ball bearings offer a reliable solution. However, their performance can be influenced by installation errors or contamination. Taking the time to ensure proper fitting and cleanliness is essential. These factors may seem small, but they have a big impact on longevity and effectiveness. Reflecting on these elements can help improve decision-making for your project.

Choosing the right deep groove ball bearings is crucial for your project. Several key factors influence your selection. First, consider load capacity. Each bearing has a specific load rating. Understand the radial and axial loads your application will experience. This understanding helps ensure longevity and performance.

Next, think about the environment. Bearings may need to resist dirt, moisture, or extreme temperatures. If they are exposed to harsh conditions, look for materials that provide additional protection. Seals or shields can help extend the lifespan of your bearings. They can be critical yet often overlooked.

Finally, examine the precision class. Each application may require different levels of accuracy. High-speed applications often need bearings with tighter tolerances. Misjudging this can lead to operational inefficiencies. Reflect on your requirements carefully. The right choice can enhance your project’s efficiency, but a poor decision could result in increased costs and maintenance efforts.

Deep groove ball bearings are widely used in various industries due to their versatility. They can support both radial and axial loads. There are different types of deep groove ball bearings available, each suited for specific applications. For example, single-row deep groove ball bearings are the most common type. They are typically used in electric motors and household appliances.

Another variant is the double-row deep groove ball bearing. This type can handle heavier loads due to its larger size and design. According to industry reports, the global deep groove ball bearing market is expected to grow significantly, reaching approximately $15 billion by 2025. This growth indicates the increasing demand across automotive and machinery sectors.

The material of the bearing is also crucial. Steel and ceramic are popular choices. Steel bearings tend to be more affordable, but ceramic bearings offer better performance in high-speed applications. Choosing the wrong type or material may lead to frequent failures. This can result in downtime and unnecessary costs. Consider the specific requirements of your project before making a selection.

When selecting deep groove ball bearings, evaluating load capacity and speed ratings is crucial. Load capacity indicates how much weight a bearing can handle. Manufacturers provide basic load ratings, usually expressed in kilonewtons (kN). For example, a typical bearing might have a dynamic load rating of around 20 kN. This means it can reliably support substantial loads.

Speed ratings are equally important. Each bearing has a maximum speed limit. Exceeding this can result in rapid wear or failure. For instance, a bearing rated for 3,600 RPM will experience significant issues if pushed beyond its limits. Industry standards recommend checking these ratings against your project requirements.

It's vital to consider the environment as well. Temperature and lubrication affect bearing performance. A bearing suitable for 70°C may not perform at all in higher heat conditions. Striking a balance between load capacity and speed ratings requires careful thought. Oversights can lead to operational failures, which can be costly. This might involve revisiting initial specifications unexpectedly. Understanding these parameters helps in making informed decisions.

| Bearing Type | Load Capacity (kg) | Speed Rating (RPM) | Inner Diameter (mm) | Outer Diameter (mm) |

|---|---|---|---|---|

| 6200 | 23 | 30,000 | 10 | 30 |

| 6300 | 40 | 28,000 | 10 | 35 |

| 6400 | 60 | 25,000 | 20 | 40 |

| 6800 | 30 | 35,000 | 10 | 24 |

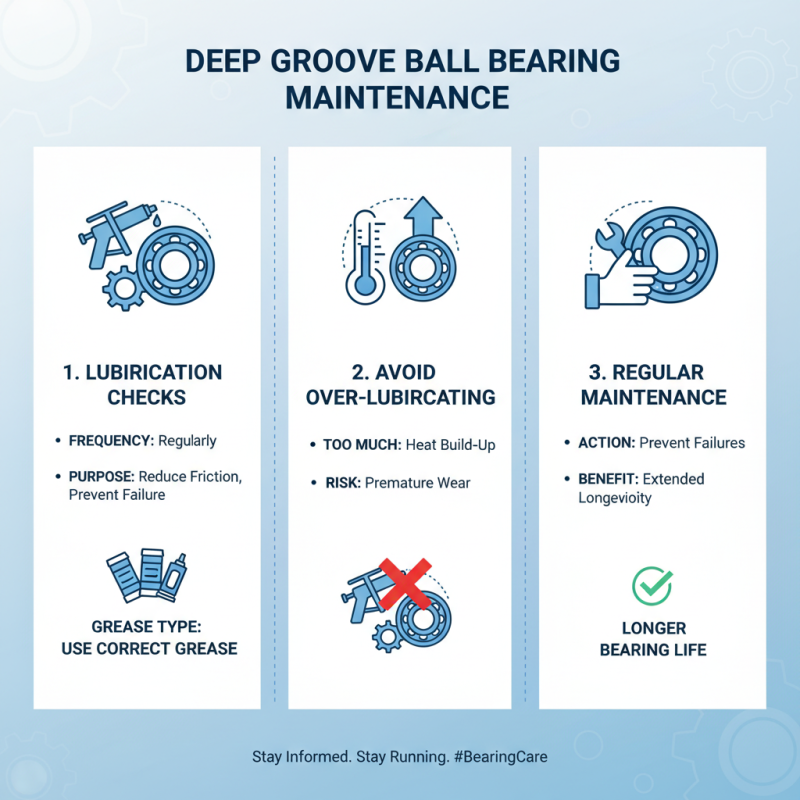

Maintaining deep groove ball bearings is crucial for their longevity. Regular maintenance can prevent unexpected failures. Check lubrication levels frequently. Proper lubrication reduces friction. Use the correct type of grease for your bearings. Over-lubricating can be as harmful as under-lubricating. Too much grease may cause heat build-up. This might lead to premature wear.

Inspect bearings for dirt or contaminants. Debris can significantly shorten their lifespan. Clean the bearings gently using appropriate solvents. Ensure they dry completely before reinstallation. Listen for unusual noises during operation. These sounds could indicate wear or misalignment. Addressing these issues early can prevent more significant problems later.

Keep operating conditions in mind. Excessive heat can damage bearings. Monitor the temperature regularly. If it exceeds safe limits, consider adjustments to your setup. You might need better ventilation or a different setup altogether. Ignoring these factors could result in costly repairs. Reflect on your maintenance routine. Small adjustments can lead to longer-lasting performance. Every small detail counts in extending the life of your ball bearings.