Choosing the right Taper Roller Bearing is crucial for the success of engineering projects, as these components play a pivotal role in minimizing friction and handling heavy loads in various applications.

Taper roller bearings are uniquely designed to accommodate both radial and axial loads, making them ideal for diverse engineering requirements. However, with the myriad of options available on the market, selecting the most suitable bearing can be a daunting task for engineers and designers.

Taper roller bearings are uniquely designed to accommodate both radial and axial loads, making them ideal for diverse engineering requirements. However, with the myriad of options available on the market, selecting the most suitable bearing can be a daunting task for engineers and designers.

This guide aims to provide insights into the key factors to consider when choosing taper roller bearings, including load ratings, dimensions, material specifications, and environmental considerations. By understanding these elements, professionals can ensure optimal performance, longevity, and reliability in their projects, ultimately leading to enhanced efficiency and reduced maintenance costs.

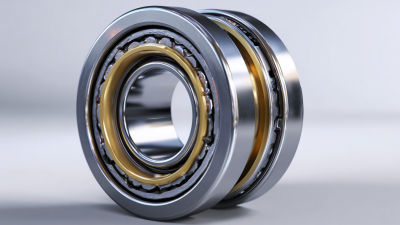

Taper roller bearings are essential components in various engineering applications due to their ability to handle both radial and axial loads. Understanding the different types of taper roller bearings is crucial for selecting the right one for your project. They are categorized based on their design, including single-row, double-row, and four-row configurations. Single-row taper roller bearings are widely used in automotive and industrial machinery, offering a compact solution with good load-carrying capacity. In contrast, double-row bearings provide greater stability and are ideal for applications requiring higher load capacities.

When considering applications, the usage context significantly influences the choice of taper roller bearing. For example, in heavy machinery or construction equipment, robust designs that can tolerate harsh conditions are necessary. You may choose bearings coated with protective materials to extend their lifespan under adverse conditions. Furthermore, it's essential to evaluate factors like load ratings, speed limits, and potential misalignment. By thoroughly understanding these aspects of taper roller bearings, engineers can make informed decisions that lead to improved performance and reliability in their projects.

| Bearing Type | Load Capacity (kN) | Speed Rating (RPM) | Applications |

|---|---|---|---|

| Single Row Taper Roller Bearing | 15 - 60 | 3000 - 8000 | Automotive Axles, Gearbox |

| Double Row Taper Roller Bearing | 30 - 120 | 2500 - 6000 | Heavy Machinery, Mining Equipment |

| Four Row Taper Roller Bearing | 100 - 400 | 1500 - 4000 | Rolling Mill, Steel Industry |

| Tapered Thrust Roller Bearing | 25 - 80 | 2000 - 5000 | Marine Applications, Wind Turbines |

| Taper Roller Bearing with Seals | 20 - 70 | 3000 - 7000 | Construction Equipment, Agricultural Machinery |

When selecting taper roller bearings for engineering projects, several key factors must be considered to ensure optimal performance and longevity. One critical aspect is the load capacity of the bearing, which is influenced by the bearing design and material. According to a report from the American Bearing Manufacturers Association (ABMA), proper load calculations can enhance bearing life by up to 50%. Engineers must assess both dynamic and static load ratings to ensure they meet the specific demands of their applications.

Another important factor is the operating environment of the bearing. Taper roller bearings exposed to extreme temperatures or corrosive substances may require specialized coatings or materials. For instance, the International Organization for Standardization (ISO) emphasizes the significance of corrosion resistance in bearings operating in hostile environments, citing that bearings with appropriate surface treatments can significantly reduce maintenance costs and downtime. Additionally, consideration should be given to lubrication, as proper lubrication can decrease friction and wear, ultimately contributing to a bearing's overall efficiency and lifespan.

When selecting the appropriate taper roller bearing for engineering projects, assessing load capacity and operational conditions is crucial. Taper roller bearings are designed to accommodate both radial and axial loads, making them suitable for applications with heavy loads, such as automotive and industrial machinery. According to a report by the International Journal of Engineering Technologies, choosing bearings with a load rating sufficient to handle peak loads during operation can enhance reliability and extend service life.

Additionally, operational conditions like temperature, speed, and the potential for contamination significantly impact bearing performance. A recent study published in the Journal of Mechanical Engineering found that bearings operating above their design temperature can experience reduced fatigue life by as much as 50%. It's vital to match the bearing selection with the specific operational context to prevent premature failure. Engineering teams should utilize data from manufacturers' catalogs and load analysis tools to ensure that the bearing chosen can cope with the expected loads and environmental stresses.

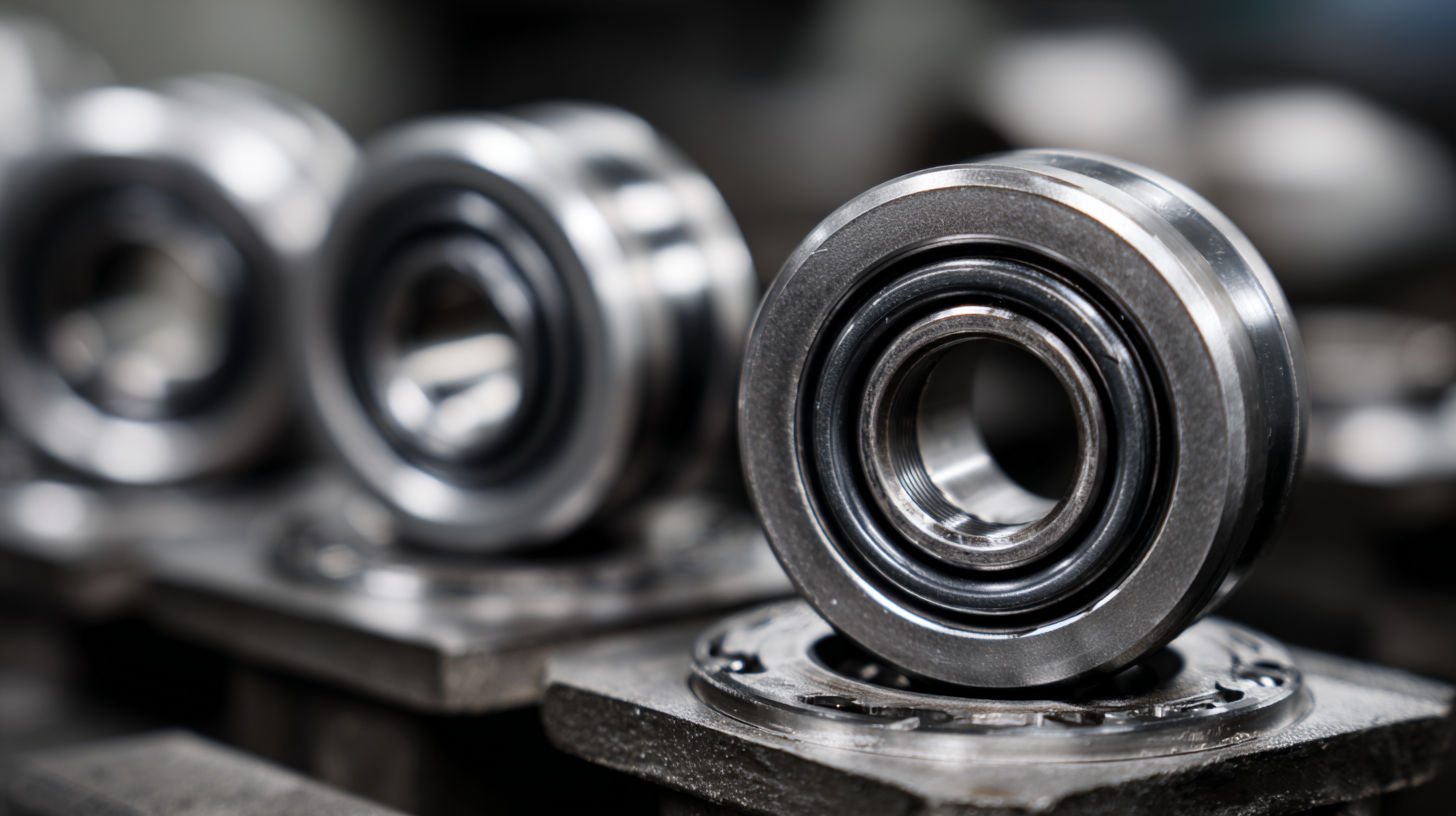

When selecting taper roller bearings for engineering projects, one essential aspect to consider is the material used in their construction. High-quality metals significantly contribute to the longevity and performance of bearings, especially under varying loads and operating conditions. According to industry reports, bearings made from high-carbon chromium steel (such as AISI 52100) exhibit superior wear resistance, allowing them to operate effectively in high-load environments. This material supports optimal fatigue life and can handle a broad range of temperatures, making it a preferred choice for engineering applications.

Additionally, advanced materials such as stainless steel offer excellent corrosion resistance, which is crucial for bearings exposed to harsh environments. Testing has shown that stainless steel bearings can maintain functionality even under moisture or chemical exposure, significantly extending their service life. A recent survey indicated that the use of stainless steel in rolling bearings can reduce maintenance frequency by up to 30%, underscoring the importance of material selection in engineering projects. Therefore, careful consideration of the bearing material is critical for achieving both performance and longevity in applications.

When selecting a taper roller bearing for your engineering projects, ensuring compatibility with your design requirements is paramount. The first step is to thoroughly understand the load conditions your application will face. Taper roller bearings are designed to handle both radial and axial loads, but their effectiveness depends on the proper match with the specific load demands of your machinery. It’s critical to analyze factors such as load ratings, bearing life, and the operational environment to choose a bearing that meets your engineering standards.

Another essential consideration is the dimensional specifications of the bearing, including its inner and outer diameter, width, and mounting features. These dimensions must align with your assembly’s design to guarantee proper fitment and performance. Additionally, the material composition and clearance specifications of the bearing should reflect the operating temperatures and speeds in your application. By diligently evaluating these parameters, you can select a taper roller bearing that not only fits but also enhances the reliability and efficiency of your engineering project.