Choosing the right tapered roller bearing is crucial for ensuring optimal performance and longevity in mechanical applications. According to a recent industry report by the Bearing Manufacturers Association, the global tapered roller bearing market is projected to reach $5 billion by 2025, highlighting its significance in various sectors, including automotive and manufacturing. The right choice not only enhances machinery efficiency but also minimizes maintenance costs, contributing to overall productivity.

Industry expert Dr. John Smith, a renowned authority in bearing technology, emphasizes the importance of selecting the appropriate tapered roller bearing for specific applications. He states, "The performance and durability of mechanical systems largely depend on how well the bearing is suited to the operational environment." This underscores the necessity of understanding key parameters such as load capacity, speed ratings, and material properties when making a selection. With the wide array of options available, buyers must navigate these considerations carefully to achieve the best outcomes for their operations.

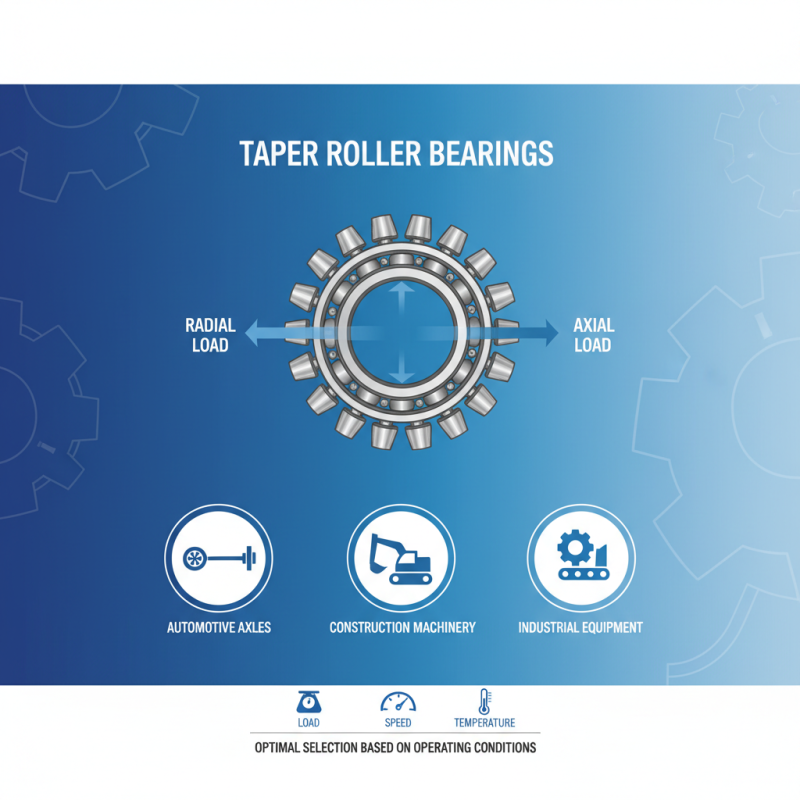

Taper roller bearings are specialized components used to support both radial and axial loads in various applications. Their unique design features inner and outer races that conically shape the roller elements, allowing them to handle heavy loads while providing stability. This characteristic makes them suitable for automotive axle systems, construction machinery, and industrial equipment, where efficiency and durability are paramount. Understanding the operating conditions—such as load capacity, speed, and temperature—will guide users in selecting the appropriate taper roller bearing for their specific needs.

When selecting taper roller bearings, it's critical to consider their application environment. For example, high-performance applications may require bearings that can operate at elevated temperatures or in harsh conditions. Additionally, the right bearing arrangement can significantly impact the overall performance, particularly in systems subject to dynamic loads. Therefore, thorough knowledge of the specific application and careful assessment of the bearing's load ratings and dimensions are essential for ensuring optimal functionality and longevity.

When selecting taper roller bearings, it is crucial to consider several key factors that can greatly impact performance and longevity. One of the primary considerations is the load rating of the bearing, which is defined by the dynamic and static load capacity. According to the ASTM International, the load rating should match or exceed the operational loads to ensure optimal performance. Selecting a bearing with an appropriate load rating not only enhances reliability but also minimizes the risk of premature failure, which can lead to costly downtime in machinery.

Another essential aspect to consider is the lubrication method. Proper lubrication can significantly affect friction and wear, influencing the bearing's lifespan. Research from the Society of Tribologists and Lubrication Engineers indicates that insufficient lubrication can reduce bearing life by up to 50%. Therefore, understanding the operating environment and the type of lubricant suitable for that environment—whether grease or oil—is vital for maintaining the efficiency of taper roller bearings. Additionally, the bearing's clearance and tolerance levels should be assessed to accommodate thermal expansion and to ensure a proper fit with housing components, further contributing to overall operational integrity.

When selecting taper roller bearings, it's crucial to consider the varying materials and design options available in the market. The choice of material significantly influences the bearing's performance, durability, and resistance to environmental factors. Common materials include chrome steel for high-load applications due to its strength and wear resistance, while stainless steel may be chosen for its corrosion resistance, especially in harsh or humid conditions. Additionally, there are options like ceramic materials that provide exceptional performance in high-speed applications but may come at a premium.

Design variations also play a vital role in the function of taper roller bearings. Different geometric configurations, such as the angle of the cone and the size of the rollers, impact load distribution and overall bearing efficiency. It's essential to match the design of the bearing with the specific requirements of the application, including load capacity and speed. Consideration of the design can help minimize friction and enhance the lifespan of the bearing.

When selecting taper roller bearings, remember to assess the operational environment and load conditions. Ensure that your choice aligns with the specific technical requirements of your machinery or project. Furthermore, always consider the bearing's compatibility with other components in your setup to avoid premature failure. By focusing on material quality and design specifications, you can enhance the performance and longevity of your taper roller bearings.

When selecting taper roller bearings, assessing the load capacity and performance requirements is critical to ensuring optimal operation in various applications. Taper roller bearings are designed to handle significant axial and radial loads; however, understanding the specific application requirements is essential. According to the International Organization for Standardization (ISO) 199:2006, the effective load capacity of taper roller bearings can vary substantially based on their design and material composition. For instance, bearing materials like high-carbon chrome steel can exhibit increased fatigue resistance, which directly influences their performance under load.

One key tip is to evaluate the dynamic and static load ratings of the bearings carefully. The dynamic load rating (C) provides insight into how much load a bearing can handle while rotating, whereas the static load rating (C0) applies to non-rotating scenarios. Generally, it's advisable to choose a bearing with a dynamic load rating at least three times higher than the calculated operating load to ensure durability and performance longevity.

Moreover, consider the application environment when selecting a taper roller bearing. Factors such as temperature, speed, and contamination levels can significantly affect bearing performance. A report from the American Bearing Manufacturers Association (ABMA) indicates that bearings operating in harsh environments may require specialized sealing solutions or lubrication systems to maintain their load capacity under challenging conditions. Ensuring that the bearing's specifications align with these requirements will enhance its overall effectiveness and longevity in your specific application.

To ensure the longevity of taper roller bearings, effective maintenance practices are crucial. Regular lubrication is one of the most critical aspects, as it reduces friction and wear between rolling elements and raceways. It is essential to use the correct lubricant type and to follow the manufacturer's recommendations regarding application frequency and quantity. Over-lubrication can lead to increased heat and potential damage, while under-lubrication might cause insufficient protection against wear.

In addition to lubrication, periodic inspections are vital. Checking for signs of wear, discoloration, or any unusual noises can help detect issues early before they escalate. It's advisable to measure the bearing's temperature during operations; any significant deviation from normal operating temperatures could indicate a problem. Moreover, ensuring that the bearings are properly aligned and installed can prevent premature wear and enhance their life span. By emphasizing these maintenance tips, operators can optimize the performance of taper roller bearings and extend their operational life.