Tapered roller bearings are essential components in many mechanical systems. They provide support for rotating shafts while minimizing friction. Proper maintenance and installation are vital for their optimal performance.

To achieve longevity, one must understand the specific requirements of tapered roller bearings. Selecting the right size and ensuring proper alignment can significantly affect wear and tear. Small errors during installation can lead to premature failure, which is often overlooked.

Despite their durability, users often neglect essential maintenance tasks. Regular inspections and lubrication are necessary to prolong their lifespan. User practices may vary, leading to unexpected issues. Addressing these common oversights can help maintain the efficiency of tapered roller bearings for years to come.

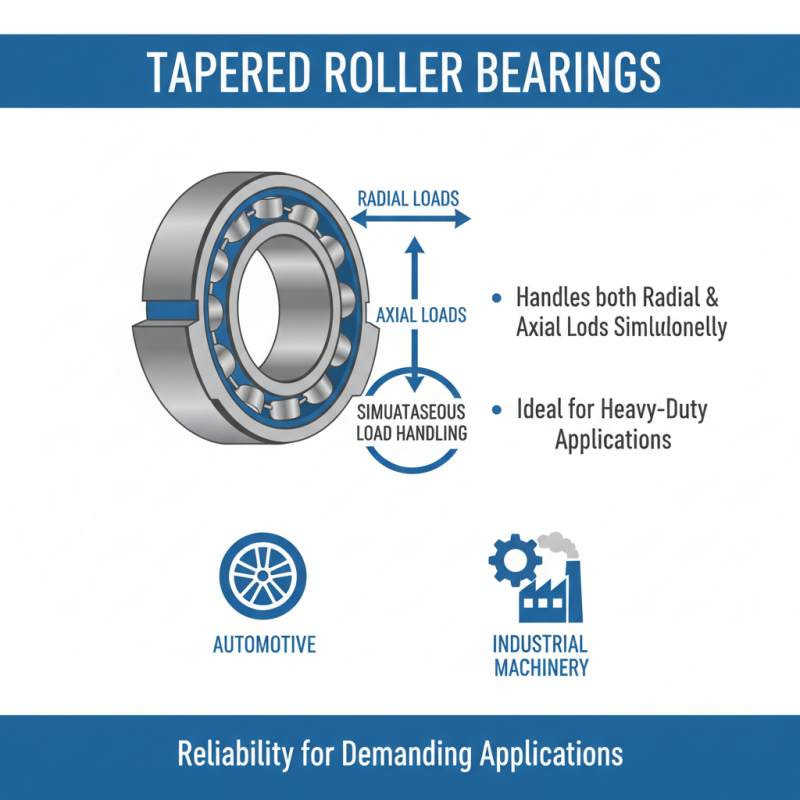

Tapered roller bearings (TRBs) are essential components in many machinery applications. They are designed to handle both radial and axial loads simultaneously. This unique capability makes them suitable for heavy-duty applications, such as in automotive and industrial machinery.

In the world of TRBs, there are several subtypes. Cone and cup designs are common. The angled surfaces ensure contact that can bear significant loads. According to a report by the International Organization for Standardization, the demand for TRBs has grown by about 5% annually due to their efficiency. However, not all TRBs are equal. Different materials and designs can impact performance and longevity.

Despite their robustness, TRBs can fail due to improper installation or lack of maintenance. Regular lubrication is crucial but often overlooked. Some studies indicate that nearly 30% of bearing failures stem from inadequate lubrication. Understanding the specifications and maintenance needs of each type is vital for reliable operation. Observing minor signs of wear early can prevent costly downtime. Being proactive often pays off in the long run.

Tapered roller bearings are essential for various applications. Their design allows them to handle both radial and axial loads. Understanding the factors that affect their performance can greatly enhance their longevity.

One critical factor is lubrication. Proper lubrication reduces friction, which leads to less wear. Yet, too much lubricant can attract debris, causing damage. Selecting the right lubricant type and quantity is vital. Operating temperatures also play a significant role.

High heat can degrade components, while extreme cold can create stiffness.

Installation quality cannot be overlooked. Misalignment during installation may lead to premature failure. Too much preload can be damaging, while too little may result in sloppiness.

Regular maintenance checks are essential to catch any potential issues early. Staying proactive prevents costly failures and extends the bearing's usable life.

When it comes to tapered roller bearings, installation is crucial for ensuring optimal functionality. According to a 2022 industry report by the American Bearing Manufacturers Association, improper installation can lead to a 40% decrease in bearing lifespan. This highlights the need for attention to detail during the setup process.

Alignment should be precise. Misalignment can cause uneven wear. This not only shortens the bearing's lifespan but may also lead to failure, costing time and resources. A simple visual inspection can help identify misalignment before it results in significant issues.

Furthermore, the use of proper tools and techniques is essential. Many technicians overlook the importance of using appropriate torque specifications. This oversight can lead to excessive play or binding. Additionally, ensuring cleanliness during installation prevents contamination, which is a common cause of bearing failure. Even slight debris can lead to increased friction and wear. A 2023 study revealed that cleanliness directly impacts performance, with dirty environments causing up to 30% lower efficiency in some installations.

Improving awareness of these installation best practices can dramatically enhance the bearing's performance and longevity.

Tapered roller bearings are essential in various machinery. Routine maintenance can significantly impact their performance. Proper lubrication is key. Use the right lubricant types and ensure they are applied correctly. This prevents overheating and reduces wear.

Check the bearing for any signs of damage regularly. Listen for unusual noises during operation. Vibrations can indicate imbalance or misalignment. Such issues can lead to premature failure. It's vital to address these concerns promptly.

Temperature monitoring is another important aspect. Ensure bearings operate within the recommended temperature range. Excessive heat can shorten their lifespan. Consider the working environment too. Exposure to contaminants might hinder performance. Regular cleaning and protective measures can help maintain optimal conditions.

Tapered roller bearings are essential for many machinery applications. However, they can face common issues that affect their performance and longevity. One frequent issue is improper installation. A misaligned bearing can lead to premature wear. Regular checks of the installation process are crucial. Installers should ensure that the bearings fit properly within the housing.

Another common problem is inadequate lubrication. Bearings require the right amount of lubricant for smooth operation. Too little oil can cause overheating. Conversely, too much can lead to contamination. Users should monitor the lubrication levels often. If there are signs of grease leakage, it is vital to address it immediately. Cleaning the bearing periodically can prevent grit buildup and ensure optimal performance.

In addition, many overlook bearing noise as a warning sign. Unusual sounds during operation often indicate wear or damage. Users should not ignore these signals. Monitoring noise can result in timely maintenance. Regular inspections will reveal clues about condition. Addressing minor issues early can prevent costly repairs later.

| Issue | Description | Solution | Frequency |

|---|---|---|---|

| Overheating | Excessive heat generation due to inadequate lubrication. | Ensure proper lubrication; use high-quality grease. | Common |

| Misalignment | Bearing rings are not aligned correctly, causing uneven wear. | Align shafts properly; install bearings according to specifications. | Moderate |

| Contamination | Foreign particles entering the bearing can cause damage. | Use sealed bearings; implement regular cleaning routines. | Frequent |

| Insufficient Load Capacity | Bearing subjected to loads exceeding its capacity. | Select a bearing with appropriate load ratings for the application. | Occasional |

| Noise and Vibration | Unusual sounds indicating potential failure or misalignment. | Inspect and repair any underlying mechanical issues. | Common |