Tapered Roller Wheel Bearings play a crucial role in the overall performance and safety of vehicles. These specialized bearings are designed to support both radial and axial loads, making them essential for the smooth operation of vehicle wheels. According to a report from the International Organization for Standardization (ISO), the efficiency of vehicle performance can be significantly enhanced by using high-quality tapered roller bearings, contributing to reduced rolling resistance and improved fuel economy. This is particularly important in a market increasingly focused on sustainability and efficiency, where even slight improvements can lead to substantial benefits.

The effectiveness of Tapered Roller Wheel Bearings is evidenced by their widespread adoption across various vehicle types, including passenger cars, trucks, and industrial machines. Data from the National Highway Traffic Safety Administration (NHTSA) indicates that proper bearing functionality is directly linked to vehicle stability and handling, which are paramount for driver safety. As vehicles continue to evolve towards greater speeds and loads, the demand for reliable and durable wheel bearings becomes increasingly critical. The integration of advanced materials and design innovations in tapered roller bearings not only enhances their longevity but also aligns with the industry's standards for performance and reliability.

Tapered roller wheel bearings play a critical role in enhancing vehicle dynamics, supporting the weight of the vehicle while allowing for smooth rotation of the wheels. These bearings are designed to handle both radial and axial loads, making them ideal for the complex forces experienced during acceleration, braking, and cornering. According to the Automotive Engineering International Magazine, the efficiency of these bearings can significantly influence a vehicle's handling characteristics, stability, and overall performance. High-quality bearings reduce friction and heat buildup, which can lead to longer tire life and improved fuel efficiency, a consideration that has been emphasized in multiple industry studies.

When incorporating tapered roller bearings, it’s essential to ensure proper installation and maintenance. Misalignment or inadequate lubrication can compromise performance and lead to premature failure. Industry reports suggest that regularly checking for signs of wear and maintaining proper lubrication levels can extend the life of these bearings.

**Tip:** Consider regularly monitoring the wear pattern on your tires, which can be an indicator of bearing health and vehicle alignment issues. Regularly scheduled inspections can also prevent minor issues from escalating, preserving both performance and safety.

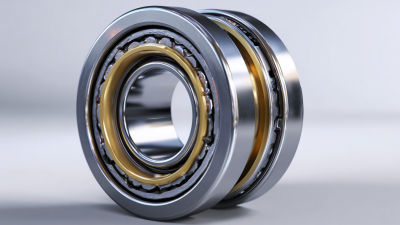

Tapered roller bearings play a crucial role in ensuring the smooth performance of vehicle wheels. Designed with a unique conical shape, these bearings can accommodate both axial and radial loads, which is essential for handling the dynamic forces exerted on a vehicle during operation. According to a report by the American Bearing Manufacturers Association, around 90% of automotive wheel bearings in vehicles today utilize tapered roller designs, underscoring their dominance in the automotive industry. This design allows for better distribution of load and increased stability, which directly contributes to enhanced vehicle handling and safety.

The functionality of tapered roller bearings stems from their ability to carry heavy loads with minimal friction. This results in better energy efficiency, which is a significant consideration for modern vehicles aiming to optimize fuel consumption. Data from a recent study indicates that vehicles equipped with high-quality tapered roller bearings can achieve a reduction in rolling resistance by up to 15%. Additionally, the tapered design promotes uniform wear and extends the lifespan of the bearings, which is essential for reducing maintenance costs and improving overall vehicle reliability. In high-performance applications, these bearings are indispensable; they facilitate smoother operation and allow for greater driving comfort, making them a vital component in contemporary vehicle engineering.

Tapered roller bearings play a crucial role in optimizing load distribution within a vehicle's wheel assembly. Unlike traditional ball bearings, the design of tapered roller bearings allows them to handle both axial and radial loads simultaneously. This unique capability is attributed to their conical shape, which ensures an even distribution of contact stress across the bearing surface. According to the American Bearing Manufacturers Association, properly engineered bearings can significantly enhance the load-bearing capacity and operational efficiency of various vehicle systems, resulting in improved overall performance.

The benefits of tapered roller bearings extend beyond just load distribution. Research from the Society of Automotive Engineers indicates that vehicles equipped with high-quality tapered roller bearings experience reduced friction and lower operating temperatures, leading to improved fuel efficiency. Additionally, these bearings have a proven track record of longevity, often lasting up to three times longer than conventional bearings in heavy-duty applications. This durability translates to fewer maintenance requirements and lower overall costs for vehicle owners, enhancing the vehicle’s performance while ensuring reliability on the road.

Tapered roller bearings are crucial components in vehicle design, primarily due to their unique ability to enhance both handling and stability. These bearings allow for the effective distribution of load across the bearing surface, which reduces friction and wear over time. The tapered design enables them to support both radial and axial loads, giving vehicles the ability to navigate turns more smoothly and maintain better contact with the road. As a result, the overall maneuverability of the vehicle improves, allowing for sharper cornering and enhanced driving responsiveness.

Moreover, the integration of tapered roller bearings significantly contributes to vehicle stability. By minimizing play, or looseness, in the wheel assembly, these bearings ensure that wheels remain properly aligned and secure during operation. This tightness translates into reduced vibrations and better control during high-speed driving or when negotiating uneven surfaces. Drivers benefit from a more predictable driving experience, leading to improved confidence on the road. Additionally, the durability of tapered roller bearings means that they can maintain consistent performance over time, further solidifying their role in optimizing vehicle handling and stability.

Maintaining tapered roller wheel bearings is crucial for enhancing their lifespan and ensuring optimal vehicle performance. Regular inspections should be conducted to identify any signs of wear or damage. This means checking for unusual noise, vibration, or excessive heat, which may indicate lubrication issues or misalignment. By addressing these problems early, vehicle owners can prevent more significant complications that could lead to bearing failure.

Lubrication is another essential aspect of maintaining tapered roller bearings. Proper lubrication ensures that the bearings can function smoothly, reducing friction and wear. It's important to use the right type of grease recommended for tapered roller bearings and to maintain the correct level of lubrication. Furthermore, clean the area around the bearings regularly to prevent contaminants from entering, which can cause premature wear. By following these maintenance tips, vehicle owners can help extend the lifespan of their tapered roller wheel bearings and enhance overall vehicle efficiency.