In the realm of mechanical engineering and design, the significance of choosing the right bearings cannot be overstated. Among the various types available, the U Groove Roller Bearing stands out for its unique design and versatile applications. This innovative bearing type features a grooved outer surface that enables it to navigate efficiently within tracks, making it ideal for systems that require smooth and reliable movement.

Understanding the benefits of U Groove Roller Bearings is essential for engineers, designers, and maintenance professionals alike. From reducing friction and wear to enhancing load capacity and operational longevity, these bearings bring a myriad of advantages to numerous industrial applications. In this article, we will delve into the top ten benefits of U Groove Roller Bearings, shedding light on why they are a preferred choice in diverse machinery and equipment. Whether you're involved in manufacturing, robotics, or transportation, the insights provided here will equip you with valuable knowledge to make informed decisions in your projects.

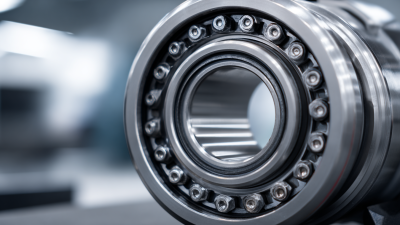

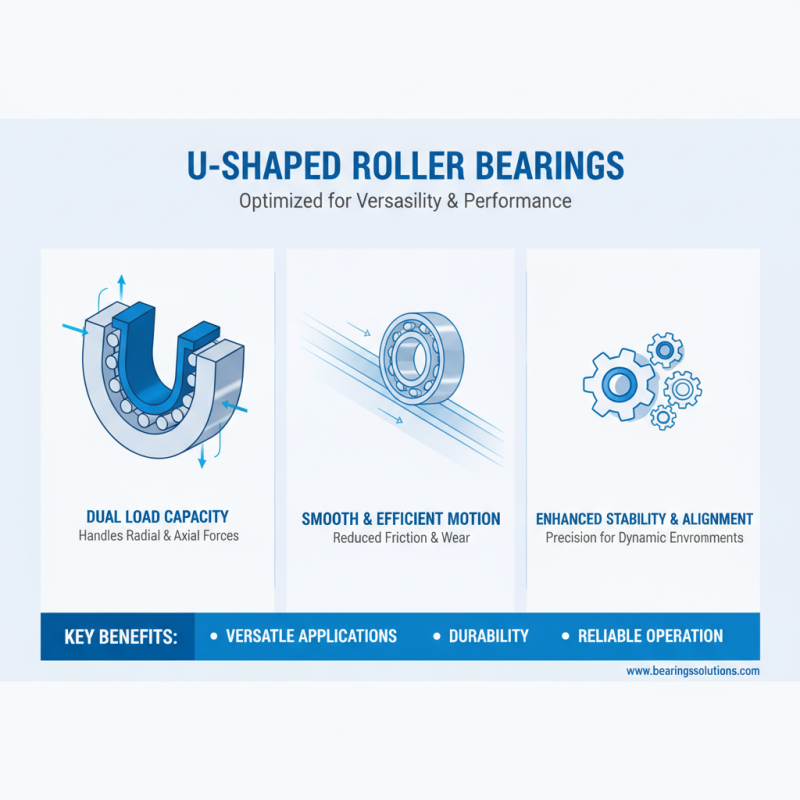

U Groove roller bearings are specialized components designed to handle various load conditions while providing smooth and efficient motion. One of their defining features is the unique U-shaped groove that allows for optimal load distribution and reduces friction during operation. This specific design enables them to accommodate both radial and axial loads, making them particularly versatile in different applications. The U shape not only enhances the bearings' stability but also facilitates better alignment with shafts and rail-like surfaces, which is crucial for performance in dynamic environments.

Another key aspect of U Groove roller bearings is their construction, which often incorporates high-quality materials aimed at increasing durability and wear resistance. This ensures longevity, even in demanding settings. The design also allows for easy installation and maintenance, contributing to their efficiency in various machinery setups. With reduced operating temperatures and noise levels, U Groove roller bearings stand out in terms of reliability, making them an excellent choice for applications in automotive, industrial, and other engineering sectors.

U groove roller bearings are becoming increasingly popular due to their unique design that allows for enhanced load distribution. This feature significantly reduces the stress concentration on the bearings, ultimately leading to improved longevity. With a more even weight distribution across the rolling elements, the bearings are less prone to wear and tear, making them ideal for applications with heavy loads or dynamic movements.

Maintaining proper lubrication is crucial for maximizing the lifespan of U groove roller bearings. Regularly check and replace the lubricant as needed, ensuring that the bearings operate smoothly without unnecessary friction. A well-lubricated bearing not only reduces wear but also aids in heat dissipation, preventing overheating and potential failure.

Additionally, pay attention to the alignment of the bearings during installation. Misalignment can lead to uneven load distribution, negating the benefits of the U groove design. Ensuring proper alignment will enhance performance and maximize the lifespan of the bearings. Taking these proactive measures can greatly impact the reliability and longevity of your U groove roller bearings, making them an excellent investment for your machinery.

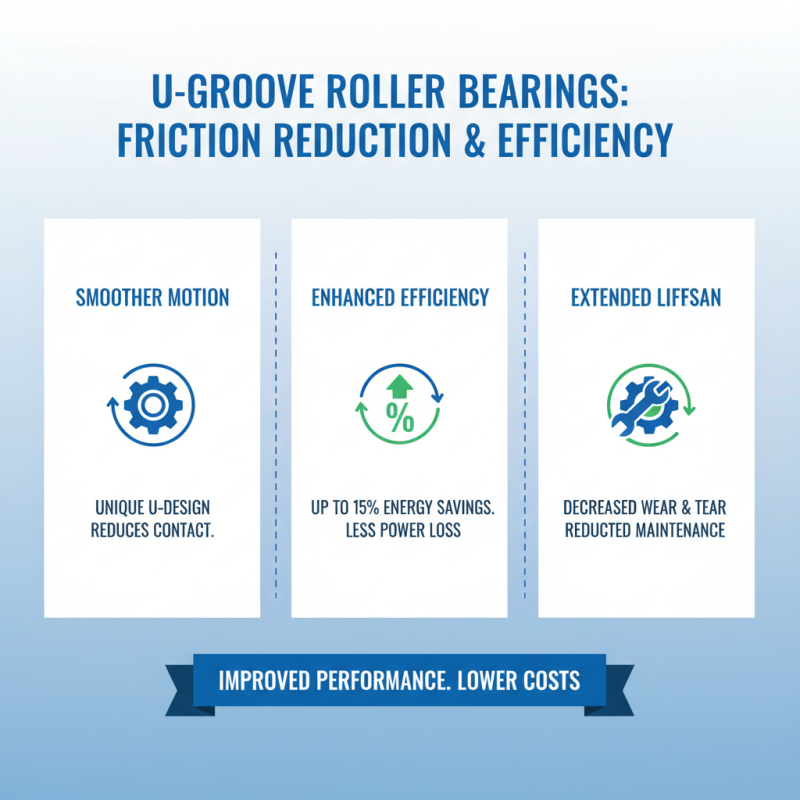

U groove roller bearings are increasingly recognized for their ability to significantly reduce friction and enhance efficiency across various mechanical applications. These bearings provide a unique design that allows for smoother motion and less energy loss due to friction. According to recent industry reports, applications utilizing U groove roller bearings have demonstrated an increase in efficiency by up to 15%, resulting in notable energy savings over time. This decreased friction not only leads to improved operational performance but also extends the lifespan of machinery components, thereby reducing maintenance costs and downtime.

One key benefit of incorporating U groove roller bearings is their adaptability in diverse conditions. For instance, they perform exceptionally well in applications ranging from conveyor systems to automated machinery where precise and consistent motion is crucial. A study published by the International Journal of Mechanical Engineering indicated that implementing these bearings in conveyor systems resulted in a reduction of energy consumption by approximately 12% compared to conventional bearings.

**Tips:** When selecting U groove roller bearings, consider the load capacities and environmental conditions to maximize their benefits. Regularly inspect bearings for wear and replace them as necessary to maintain peak performance. Additionally, ensuring proper lubrication can further enhance the efficiency gains realized from these bearings, as even minimal friction reduction can result in substantial energy savings in the long run.

U groove roller bearings have gained significant attention across various industries due to their remarkable versatility and performance. These bearings are particularly adept at handling radial and axial load combinations, making them an ideal choice for applications such as conveyor systems, agricultural machinery, and woodworking equipment. According to a report by Grand View Research, the global bearing market is expected to reach USD 65.3 billion by 2025, with an increasing demand for specialized bearings like U groove roller bearings that cater to specific needs in different sectors.

In the automotive industry, U groove roller bearings are used extensively in components such as sliding doors and window mechanisms. Their design allows for smooth operation, reduced friction, and enhanced durability under varying loads. A study published in the Journal of Mechanical Engineering highlights that optimized bearing design can lead to energy savings of approximately 15% in automotive applications, reinforcing the economic benefits of using U groove roller bearings.

Similarly, in the manufacturing sector, these bearings facilitate the efficient movement of heavy machinery, ensuring operational reliability and minimizing downtime, which is crucial for maintaining productivity in today’s competitive market.

Maintaining U groove roller bearings is essential for ensuring their longevity and optimal performance. Regular maintenance can significantly reduce friction, enhance load capacity, and prevent premature wear. One key aspect of maintenance is ensuring that the bearings are adequately lubricated. This prevents metal-to-metal contact and reduces heat generation during operation. Choosing the right type of lubricant based on the operating environment and load conditions is crucial. Additionally, it's important to monitor the lubricant's condition regularly, replacing it as needed to maintain effective performance.

Another important tip is to keep the bearings clean and free from contaminants. Dust, dirt, and moisture can lead to corrosion and damage, impacting the overall efficiency of the bearings. Implementing a proper sealing system can help protect the bearings from external contaminants. Regularly inspecting the bearings for signs of wear or damage can also aid in early detection of potential issues. By proactively addressing maintenance needs, users can enhance the reliability and performance of U groove roller bearings, prolonging their service life and reducing the risk of unexpected failures.

| Benefit | Description | Maintenance Tip |

|---|---|---|

| High Load Capacity | Can support both radial and axial loads efficiently. | Regularly check for alignment to avoid uneven loads. |

| Smooth Operation | Provides low friction and less heat generation. | Use proper lubrication for optimal performance. |

| Durability | Constructed with high-quality materials for longevity. | Inspect seals regularly to prevent contaminants. |

| Versatile Applications | Suitable for various industries, including robotics and automotive. | Choose bearings specific to the application for best results. |

| Easy Installation | Simple design makes for straightforward installation. | Follow manufacturer guidelines for installation procedures. |

| Less Noise | Operates quietly compared to traditional bearings. | Ensure proper alignment to minimize operational noise. |

| Cost-Effective | Provides a reliable solution for various load requirements. | Invest in quality bearings to reduce long-term costs. |

| Reduced Vibration | Minimizes vibration during operation, enhancing stability. | Regularly maintain and balance to control vibrations. |

| Improved Efficiency | Increases overall machine efficiency and performance. | Monitor performance metrics to ensure efficiency improvements. |

| Enhanced Safety | Reduces the risk of failure, leading to safer operations. | Schedule regular inspections for preventive care. |