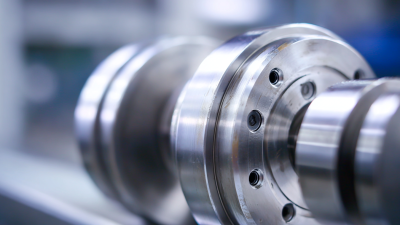

In the world of industrial machinery, "V Groove Bearings" play a crucial role in ensuring smooth operation. Experts, like Dr. Mark Thompson, emphasize their importance by stating, "V Groove Bearings reduce friction and enhance performance." This technology has transformed how various industries operate, offering benefits that surpass traditional bearing systems.

V Groove Bearings are designed for precision and efficiency. They provide stability and reduce downtime in manufacturing processes. The unique groove profile allows for smoother movement along rails. This translates to heightened efficiency in operations. However, users should regularly assess their performance. Ignoring maintenance can lead to unexpected failures.

Despite the advantages, there are challenges with V Groove Bearings that require attention. Not all applications benefit equally from this technology. Users must choose wisely based on specific needs. In some cases, V Groove Bearings might underperform if not correctly aligned. Understanding these nuances is vital for maximizing their potential.

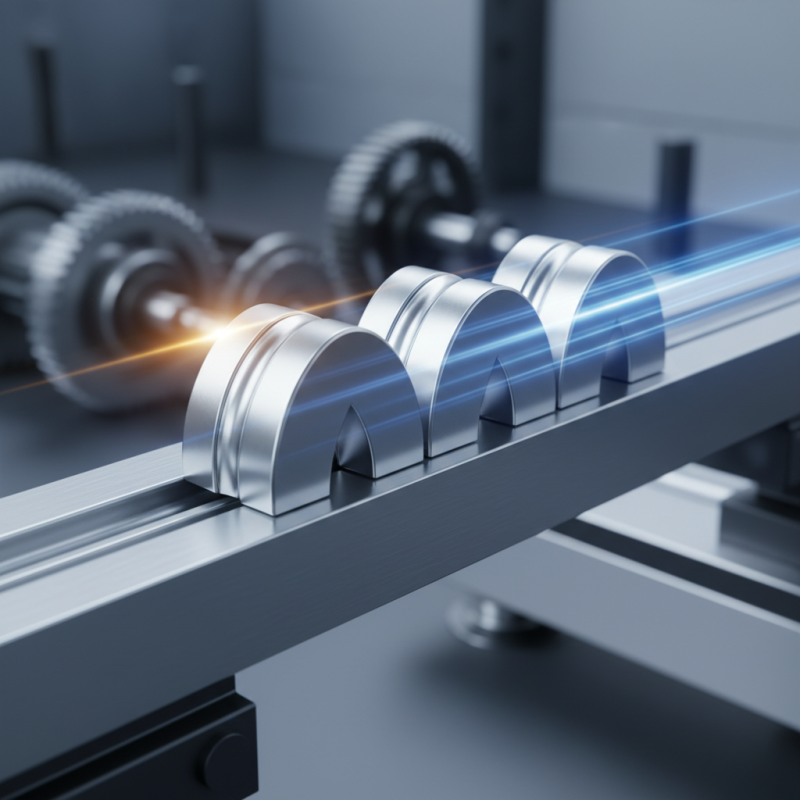

V groove bearings are increasingly popular in various industrial applications due to their unique design. These bearings provide efficient movement on flat surfaces, which is essential for conveyor systems and automated machinery. According to industry reports, using V groove bearings can enhance operational efficiency by up to 30%. This is crucial for industries that rely on precision and speed.

In automated environments, V groove bearings ensure smooth sliding and movement. They are designed to handle heavy loads while minimizing friction. A study from the International Journal of Industrial Engineering noted that machines equipped with V groove bearings experience 25% less wear and tear. This longevity can lead to significant cost savings over time, reflecting positively on maintenance budgets.

However, it is important to note that improper installation or misalignment can reduce the effectiveness of V groove bearings. Regular inspections are necessary to maintain their optimal performance. Some operators may overlook lubrication, which is vital for reducing friction. Ignoring these factors can lead to operational inefficiencies, which is a concern for industries aiming for maximum productivity. Balancing proper use and maintenance is essential for realizing the full benefits of V groove bearings.

| Benefit | Description |

|---|---|

| Smooth Operation | V Groove bearings provide a stable rolling motion, reducing friction for a smoother operation. |

| High Load Capacity | Designed to support significant loads while maintaining operational efficiency. |

| Durability | Made from high-quality materials that resist wear and tear, ensuring longevity. |

| Versatility | Applicable in various industrial settings such as conveyors, machine tools, and automated systems. |

| Easy Installation | Designed for easy mounting and dismounting, simplifying maintenance processes. |

| Cost-Effectiveness | Long lifespan and reduced maintenance needs contribute to lower overall costs. |

| Noise Reduction | Minimizes operational noise, promoting a quieter working environment. |

| Precision Alignment | Ensures precise alignment for efficient operation and reduced wear. |

| Enhanced Safety | Fewer breakdowns and improved reliability contribute to a safer workplace. |

| Improved Efficiency | Increase productivity through the reduction of downtime and maintenance costs. |

V Groove bearings are increasingly recognized for their role in enhancing operational efficiency across various applications. Their design features a distinct V shape, allowing for smoother movement along guide rails. Such efficiency is crucial in industries that demand precision, like robotics and conveyor systems. A recent industry report highlights that machines using V Groove bearings can achieve up to a 30% increase in speed compared to traditional bearings.

One key factor contributing to their effectiveness is reduced friction. The innovative design minimizes contact points, resulting in less heat generation. This heat reduction can prolong bearing life significantly. In fact, studies suggest that properly lubricated V Groove bearings can outlast standard bearings by as much as 40%. Additionally, the self-aligning properties help maintain stability even under load, mitigating wear and tear over time.

Despite these advantages, there are considerations. Installation requires careful alignment to reap the maximum benefits. Misalignment can lead to a decrease in performance. Regular maintenance is also vital, as neglect can reduce the lifespan of the bearings. Balancing these factors is essential for optimizing the operational benefits associated with V Groove bearings.

V groove bearings are known for their durability and longevity. According to industry reports, these bearings can last up to 50,000 hours in optimal conditions. This extended lifespan reduces the frequency of replacements, which can be costly and time-consuming. Users often report fewer breakdowns, leading to increased productivity.

However, it’s essential to consider that not all applications yield the same results. Some users have noted premature wear in harsh environments. Factors like temperature, load, and lubrication play a critical role in performance. For instance, operating in extreme heat can shorten the life of V groove bearings by nearly 30%.

Maintenance practices can also impact durability. Regular inspections can help identify issues before they escalate. Industry data suggests that well-maintained bearings can exceed their expected lifespan by up to 20%. Investing in proper care is key to maximizing these benefits.

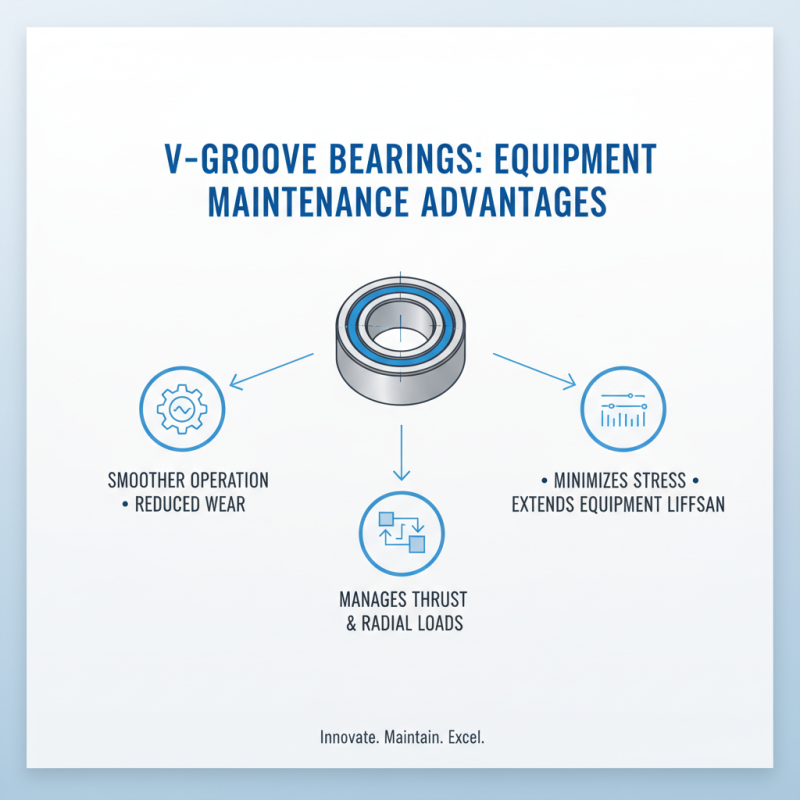

V groove bearings offer significant advantages for equipment maintenance. Their design allows for smoother operation, which can lead to reduced wear and tear on machinery. A key aspect is their ability to manage thrust and radial loads effectively. This characteristic helps minimize stress on machine components, extending their lifespan.

Maintenance costs are notably impacted by the choice of bearings. With v groove bearings, downtime can be reduced due to fewer breakdowns. This translates into savings on repairs and replacement parts. However, not all applications may benefit equally from this technology. In some cases, improper installation can lead to premature failure. It’s essential to carefully assess the specific needs of your equipment.

Incorporating v groove bearings should be a well-thought-out decision. Regular monitoring is crucial to ensure they perform optimally. Maintenance teams should be trained on best practices for handling these components. Ignoring these factors may lead to costly errors. Investing time in training and evaluation can yield substantial savings in the long run.

V groove bearings have gained popularity in precision machinery due to their unique design. This design allows for smooth operation, making them ideal for applications requiring high precision. The performance advantages are significant. Studies show that these bearings can reduce friction by up to 30%, enhancing overall efficiency.

Moreover, the stability they provide is crucial in various operations. A report from the International Journal of Precision Engineering estimates that V groove bearings can extend the operational lifespan of machinery by 25% under optimal conditions. This is particularly beneficial in harsh environments, where wear and tear can compromise performance. However, installation may require careful alignment, which can be a drawback if not done properly.

In addition to durability, V groove bearings excel in load distribution. This feature helps in maintaining consistent performance despite varying loads. Yet, it's important to acknowledge that improper maintenance can lead to performance issues. Regular checks and adjustments are essential for optimal function. Keeping a close eye on these aspects can make a significant difference in machinery performance.