Cylindrical roller bearings play a crucial role in various mechanical applications, providing the necessary support and efficiency for rotating shafts. Their design features allow for the accommodation of high radial loads while maintaining the capability to handle moderate axial loads, making them indispensable in industries such as automotive, manufacturing, and aerospace. Understanding the fundamental characteristics and advantages of cylindrical roller bearings is essential for engineers and technicians who aim to optimize machinery performance and reliability.

In this article, we will explore the top ten features of cylindrical roller bearings that you should be aware of. From their unique geometric configurations to the materials used in their construction, each feature contributes to their effectiveness and longevity in demanding environments. Whether you're involved in the design of a new system or maintaining existing equipment, a thorough understanding of these bearings can significantly enhance operational efficiency and reduce downtime. Join us as we delve into the specifics of cylindrical roller bearings and uncover the vital components that make them a cornerstone of modern mechanical systems.

Cylindrical roller bearings are essential components in various industrial applications, designed to handle high radial loads and offer excellent performance. One key characteristic is their high load-carrying capacity due to the line contact between the rollers and the raceways, facilitating efficient stress distribution. This design minimizes friction, making them ideal for high-speed operations and reducing wear over time.

Tips: When selecting cylindrical roller bearings, consider the operating environment. Factors such as temperature, lubrication, and contamination can significantly impact performance. Ensure you choose the right size and tolerance to maximize efficiency and longevity.

Another significant feature of cylindrical roller bearings is their ability to accommodate axial displacements. Some designs come with an inner or outer ring that allows for axial movement, making them suitable for applications with shaft expansion or contraction. This flexibility is crucial in maintaining alignment and ensuring smooth operation under varying thermal conditions.

Tips: Regular maintenance can prolong the lifespan of cylindrical roller bearings. Checking for wear and tear, ensuring proper lubrication, and monitoring operating temperatures can help identify issues before they lead to failure.

Cylindrical roller bearings are engineered for high radial load capacity and are particularly suitable for applications where space is limited. One of their primary types is the single-row cylindrical roller bearing, which is widely used in various machinery such as electric motors and gearboxes. This type efficiently accommodates radial loads in a compact design, making it an excellent choice for applications requiring high performance without extensive space consumption.

Another important variant is the double-row cylindrical roller bearing, which can handle heavier loads due to its two rows of rollers. These bearings are often found in heavy machinery, such as construction and mining equipment, where they support higher pressures and shock loads. Additionally, there are also specialized designs like the full complement cylindrical roller bearing, which contains the maximum number of rollers, resulting in increased load-carrying capacity. These variants are favored in applications where durability and reliability are crucial, such as in industrial gearboxes and automotive components. Overall, understanding the types and their applications is essential for selecting the right cylindrical roller bearing for specific operational needs.

| Feature | Description | Application |

|---|---|---|

| High Load Capacity | Cylindrical roller bearings can accommodate heavy radial loads due to their design. | Heavy machinery, industrial motors |

| Reduced Friction | These bearings offer lower friction compared to other designs, improving efficiency. | Automotive engines, electric drives |

| High Speed Capability | Designed to handle high speeds without sacrificing performance. | Turbines, gearboxes |

| Various Designs | Available in single-row, double-row, and multi-row configurations. | Conveyor systems, mining equipment |

| Resistance to Deformation | They maintain shape and functionality even under load. | Construction equipment, compressors |

| Ease of Installation | Designed for straightforward mounting and dismounting. | Maintenance applications, assembly lines |

| Low Noise Operation | Engineered to minimize operational noise. | Quiet machinery, electric motors |

| Long Service Life | Designed for durability, reducing replacement frequency. | Heavy-duty applications, industrial machinery |

| Customizable Sealing Options | Available with various sealing options to protect against contaminants. | Outdoor equipment, food processing industry |

| Wide Temperature Range | Operates effectively in both high and low-temperature environments. | Aerospace, cryogenic applications |

Cylindrical roller bearings are renowned for their ability to support substantial loads while maintaining efficient performance in various applications. One of the key factors influencing their load capacity is the geometry of the rollers and the raceways. The larger the contact area between these components, the higher the load they can bear. This geometric configuration not only increases the bearing's ability to withstand radial loads but also enhances its overall stability under varying operational conditions.

Another critical performance factor is the type of lubrication used within the bearing system. Proper lubrication reduces friction between the rolling elements and raceways, which diminishes wear and tear over time. Enhanced lubrication systems can also help in managing heat dissipation, ensuring that the bearing operates efficiently even under high-speed conditions. Maintaining optimal lubrication levels is essential for maximizing load capacity and extending the operational lifespan of cylindrical roller bearings, making it a vital aspect for engineers and maintenance teams to monitor.

Maintenance of cylindrical roller bearings is crucial for ensuring optimal performance and extending their lifespan. According to industry reports, inadequate maintenance accounts for approximately 20-30% of bearing failures. Thus, it is essential to implement effective strategies to maximize their efficiency.

One vital tip for maintaining cylindrical roller bearings is regular lubrication. Proper lubrication minimizes friction and wear, significantly enhancing the lifespan of the bearing. It is recommended to use high-quality grease or oil formulations that align with the operational conditions and loads. Regularly checking and replenishing lubricant levels can help avoid overheating and premature failure.

Another important aspect is the monitoring of operating conditions. Bearings should be inspected frequently for any signs of misalignment or wear. Vibration analysis can be a beneficial diagnostic tool, as increased levels of vibration often indicate potential issues. Additionally, environmental conditions play a significant role; keeping bearings free from contamination and moisture can drastically improve their reliability and performance. By adhering to these maintenance tips, one can ensure the longevity and efficiency of cylindrical roller bearings.

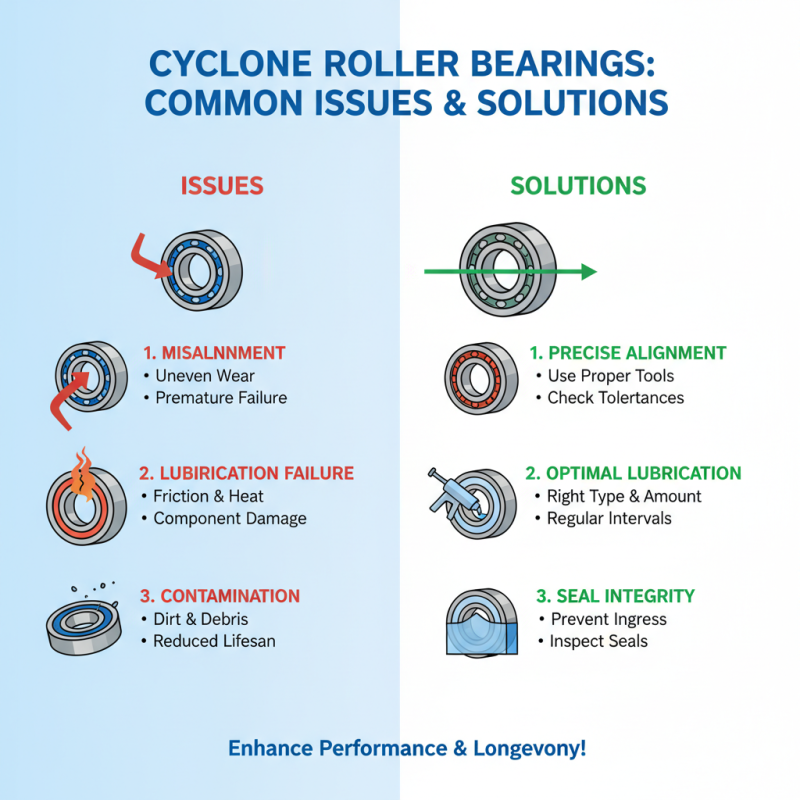

Cylindrical roller bearings are widely used in various applications due to their ability to handle high radial loads and provide excellent stability. However, like any engineering component, they can encounter common issues that may affect their performance and longevity. One prevalent problem is improper alignment during installation, which can lead to uneven wear and premature failure. Ensuring precise alignment can significantly mitigate this risk and enhance bearing lifespan.

Another frequent issue is inadequate lubrication, which may result in overheating and increased friction between rolling elements. Regularly checking lubrication levels and types suitable for the specific operating conditions is crucial. Additionally, contamination from external particles can compromise bearing integrity and functionality. Implementing effective sealing mechanisms and routine cleaning can help keep these contaminants at bay, thereby prolonging the lifespan and efficiency of cylindrical roller bearings. Understanding these common issues and their remedies is vital for maintaining optimal performance in machinery that relies on these bearings.