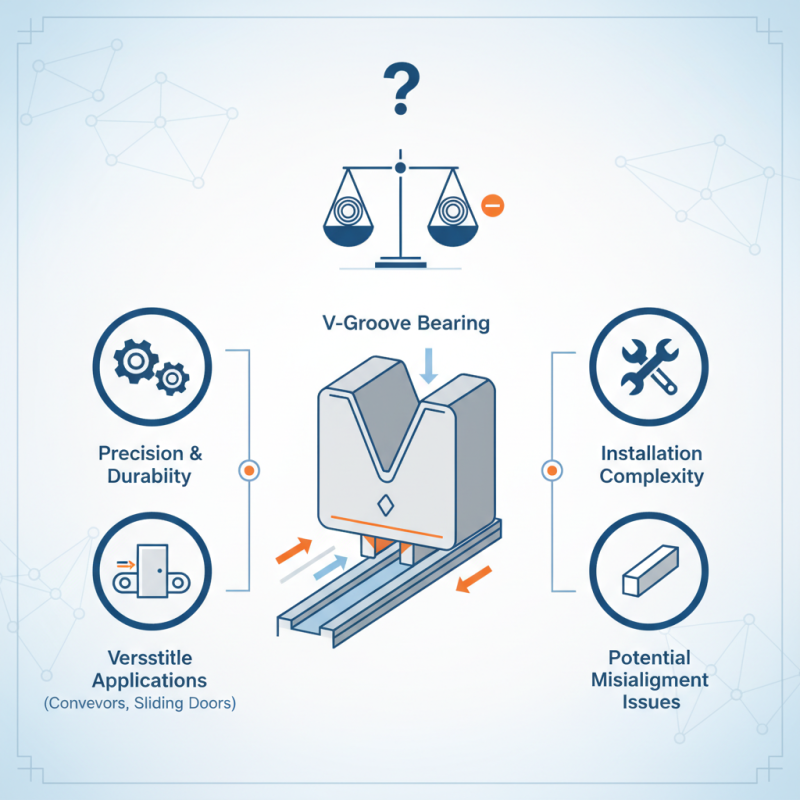

When selecting components for machinery, the choice of bearing can greatly affect performance. V Groove Bearings stand out in the industry for their unique design and functionality. Experts like John Smith, a leading figure in the bearing industry, have noted, "V Groove Bearings offer precision and durability that traditional bearings cannot match."

These bearings are designed to run smoothly on rails, providing reliable support for heavy loads. Their construction makes them ideal for various applications, including conveyors and sliding doors. However, it’s essential to consider the specific requirements of your machinery. Not every application will benefit from a V Groove Bearing.

While many praise their efficiency, some users report issues with misalignment or installation complexity. These factors should not be overlooked. Choosing the right bearing isn't always straightforward. Evaluating all options and understanding the strengths and weaknesses of V Groove Bearings is crucial for optimal machinery performance.

V groove bearings are increasingly popular in machinery applications. They offer unique advantages that make them well-suited for various tasks. One key benefit is their ability to provide smooth operation. This is essential in systems that require precise movements. A study by the American Bearing Manufacturers Association found that properly lubricated V groove bearings can increase efficiency by up to 20%.

Additionally, V groove bearings are designed to handle misalignment. This feature is vital in many industrial settings where conditions are not perfect. According to research published in the Journal of Mechanical Design, bearings that accommodate misalignment can reduce wear and tear significantly. This prolongs the life of machinery components, saving costs in the long run.

However, it’s crucial to note that the installation process can be challenging. If not aligned properly, these bearings may not perform optimally. Some users report issues with noise and vibration when set up incorrectly. Therefore, care and attention to detail are necessary, especially given their specialized nature. Proper training in installation techniques can mitigate these problems.

| Feature | Description | Advantages |

|---|---|---|

| Design | V Groove Bearings have a unique V-shaped groove that allows smooth movement. | Offers enhanced tracking and stability during operation. |

| Load Capacity | Engineered to handle heavy loads efficiently. | Improves the durability and lifespan of machinery. |

| Versatility | Suitable for various applications across multiple industries. | Allows for streamlined inventory management and cost efficiency. |

| Installation | Easy to install with standard mounting options. | Saves time and reduces labor costs during setup. |

| Maintenance | Requires minimal maintenance due to durable construction. | Reduces downtime and operational interruptions. |

V groove bearings are gaining traction in various industries. They provide unique advantages that can significantly enhance machinery performance. According to a report by the International Journal of Mechanical Engineering, these bearings can reduce friction by up to 40%. Less friction translates into improved efficiency, enabling machines to operate smoothly.

The design of V groove bearings allows for better load distribution. This enhances stability, especially in applications requiring precise movement. As stated in a study by the Society of Manufacturing Engineers, equipment downtime can decrease by 30% when using these bearings. This improvement can save manufacturers ample time and costs.

However, the advantages of V groove bearings don't come without challenges. They can be sensitive to misalignment, which may lead to premature wear. Additionally, specific environments might require extra lubrication. Understanding these factors is crucial for maximizing performance. Despite these drawbacks, the benefits often outweigh the limitations. With appropriate maintenance, V groove bearings can lead to remarkable improvements in machinery efficiency.

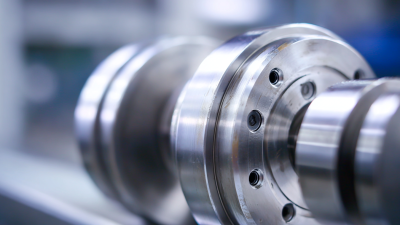

When it comes to machinery, V groove bearings are often overlooked. Their design plays a crucial role in performance. Made from materials like stainless steel or polymer, these bearings offer durability. Stainless steel provides strength, while polymer offers resistance to corrosion. The choice of material affects longevity and efficiency. It’s essential to consider the working environment when selecting the right material.

The design of V groove bearings allows for smooth motion along tracks. This specific geometry reduces friction and wear, improving overall functionality. However, not all designs are perfect. Sometimes, a slight misalignment can cause complications. It’s important to assess the installation setup. Proper fitting ensures optimal performance. Keeping an eye on wear and tear is essential too. Regular maintenance can prevent unexpected breakdowns and improve lifespan.

Ultimately, choosing the right material and design for V groove bearings can make or break your machinery's efficiency. While the advantages are clear, it’s crucial to remain vigilant about potential issues. In mechanics, success relies on the small details. Overlooking any aspect can lead to larger problems down the line. Ensure that each component is up to standard.

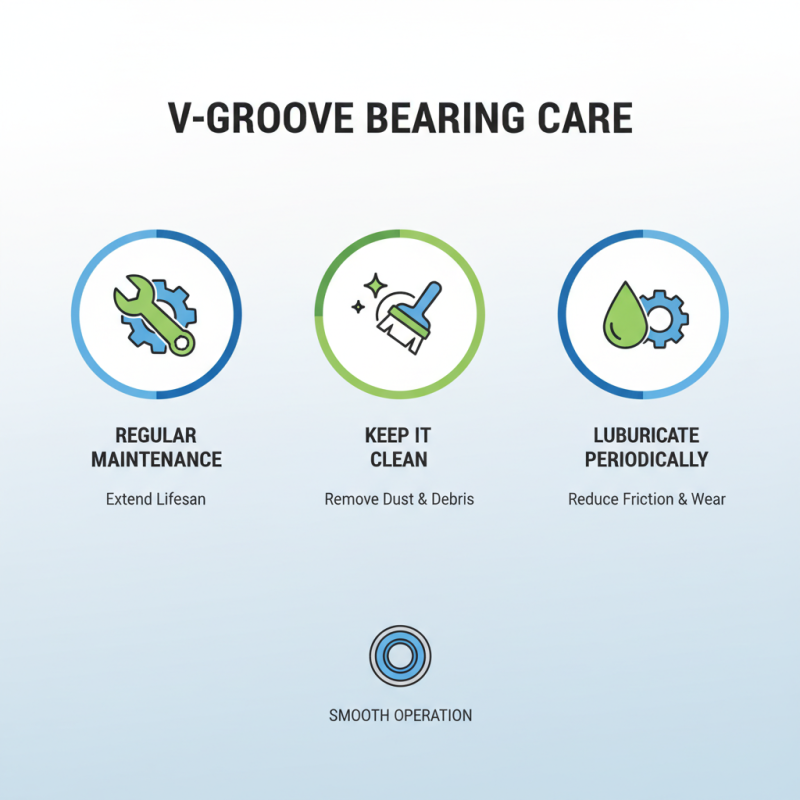

V groove bearings are essential components in many types of machinery. They require regular maintenance to perform at their best. Proper care can extend their lifespan significantly. A simple yet effective step is to keep the bearings clean. Dust and debris can cause wear and lead to failure. Use a soft cloth to wipe away any build-up.

Lubrication is another critical factor. The right grease can reduce friction and protect against corrosion. However, excessive grease can attract dirt. Aim for a balanced application. It’s vital to check the bearings periodically for any signs of wear or damage. If you encounter noise or irregular movement, it might be a warning sign.

Temperature monitoring is also important. Overheating can lead to premature failure. Plan for regular inspections, especially in high-use scenarios. Create a maintenance schedule and stick to it. Reflecting on your routine can reveal areas for improvement. Small adjustments today can lead to better performance tomorrow.

When choosing a V groove bearing, it's essential to consider your specific machinery needs. Different applications require different bearing characteristics. For instance, load capacity plays a significant role in your choice. If your machinery handles heavy loads, selecting a robust bearing is crucial. On the other hand, lighter machines may benefit from more delicate designs. Each application demands its own balance of strength and precision.

Another important factor is the environment in which the bearing will operate. Dusty or wet conditions can affect performance. Sealed bearings may be a good option for such environments. However, they can be more expensive. So, you must evaluate whether the added cost is justified. Often, users overlook the long-term costs of degradation due to harsh conditions.

Ultimately, the V groove bearing's dimensions must match your machinery setup exactly. A mismatch can lead to functionality issues. It's vital to measure the groove accurately. Many make the mistake of relying solely on specifications. But real-world fitting can differ, requiring careful examination. All these choices may lead to frustration, but they also offer opportunities for reflection on machinery needs.