A wheel hub bearing is a crucial component in your vehicle’s wheel assembly. It supports the wheel’s rotation and absorbs road shocks. Understanding its function can help in maintaining your car.

These bearings are located at the wheel hub and provide a smooth interface. They reduce friction between moving parts, allowing the wheels to spin freely. However, they can wear out over time, leading to performance issues.

When a wheel hub bearing fails, it can cause noisy drives or uneven tire wear. This not only affects vehicle handling but can be dangerous. Regular checks for signs of wear can prevent accidents and costly repairs. Maintenance matters.

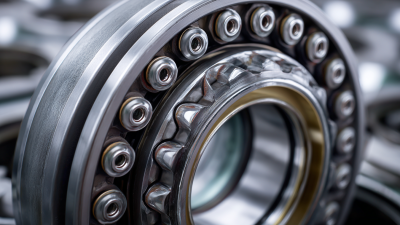

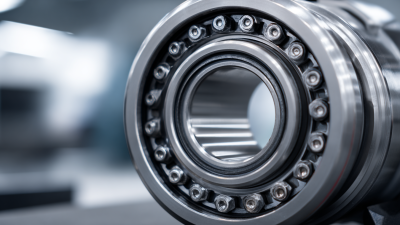

A wheel hub bearing is a crucial component of a vehicle's wheel assembly. It connects the wheel to the axle and allows smooth rotation. Most vehicles use a combination of steel balls or rollers and raceways within these bearings. These parts provide low friction for spinning and reduce wear.

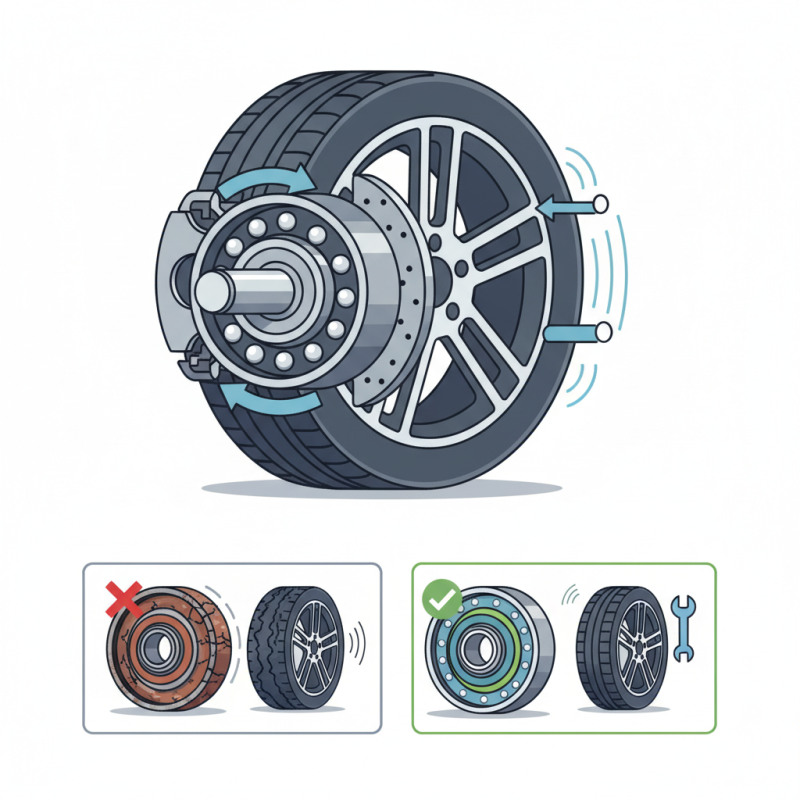

Over time, wheel hub bearings can wear down. This wear may lead to noise or vibration in the vehicle. Drivers might notice a grinding sound or even a wobbling wheel. If left unchecked, these signs suggest that the bearings aren't functioning well. Regular maintenance and inspection are essential.

The design of a wheel hub bearing is both simple and complicated. Various elements must work together perfectly. Misalignment or contamination can harm their function. Proper installation is critical, yet some may overlook it. It may seem straightforward but often requires skill. Understanding these details can empower vehicle owners to take better care of their wheels.

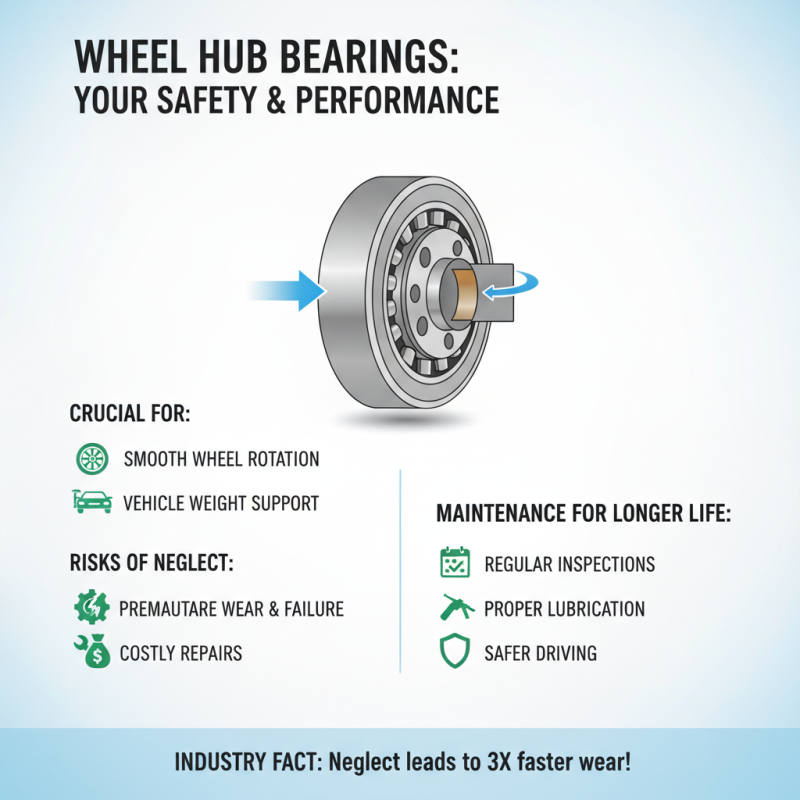

Wheel hub bearings play a crucial role in vehicle performance and safety. They allow the wheels to rotate smoothly and support the weight of the vehicle. According to industry reports, a significant percentage of vehicle failures are linked to wheel hub bearing issues. In fact, approximately 25% of all vehicle-related accidents can be traced back to faulty bearings. This staggering statistic underscores the importance of regular maintenance.

When wheel hub bearings wear down, they can lead to uneven tire wear and reduced handling ability. This deterioration often goes unnoticed until it's too late. Many drivers are unaware that signs like noise or vibration indicate something may be wrong. Inspecting wheel hub bearings is often overlooked during routine checks. It is a missed opportunity for prevention and safety.

Properly functioning wheel hub bearings enhance stability and brake efficiency. A study involving various vehicle models found that vehicles with well-maintained bearings exhibit 30% better braking performance. Furthermore, the financial aspect cannot be ignored. Repairing or replacing wheel hub bearings can prevent costly damage to other vehicle components. Maintaining these bearings is not just about performance; it is about ensuring the safety of every passenger on board.

Wheel hub bearings are essential components in a vehicle's wheel assembly. They allow the wheel to rotate smoothly while supporting the weight of the vehicle. However, like any mechanical part, they can fail. Common issues include wear from external debris and insufficient lubrication. These problems can lead to safety concerns, such as reduced braking efficiency.

According to a recent industry report, approximately 20% of vehicle failures are attributed to wheel hub bearing issues. Drivers often notice unusual sounds or vibrations when a bearing is failing. Ignoring these signs can lead to more severe damage, including complete wheel lockup. The average cost of replacement can range from $300 to $800 per bearing, depending on the make and model of the vehicle.

In some cases, lack of maintenance contributes to premature bearing failure. Regular inspections can help mitigate risks. A small investment in maintenance can save money and ensure safety. Surprisingly, many drivers neglect this critical component until it's too late. This oversight can lead to dangerous driving conditions and expensive repairs.

Wheel hub bearings are crucial for vehicle performance. They allow the wheels to rotate smoothly and support the weight of the vehicle. Regular maintenance can extend their lifespan and ensure safer driving. According to industry studies, neglected wheel bearings can lead to premature wear, resulting in costly repairs.

To maintain wheel hub bearings, start with regular inspections. Check for any signs of wear or damage. Noises during driving may indicate bearing issues, requiring immediate attention. Keeping the wheel hub clean is essential. Dirt and debris can accelerate wear. A clean bearing runs smoother, which reduces friction and improves longevity.

Lubrication is another key aspect. Properly greased bearings function better and last longer. A study found that bearings with adequate lubrication can last up to 30% longer than those without. Pay attention to how you drive as well. Rough driving can stress the bearings, leading to faster deterioration. Reflecting on your driving habits can help maintain your vehicle's integrity.

Wheel hub bearings are essential for maintaining vehicle performance. They allow the wheels to rotate smoothly. A well-functioning bearing enhances fuel efficiency. However, when they wear out, they create friction. Increased resistance can lead to higher fuel consumption. This means more trips to the gas station.

Handling dynamics significantly depend on wheel hub bearings. When they are in good condition, steering feels responsive. Drivers experience stability while cornering and braking. Conversely, damaged bearings can lead to vague steering. This instability might challenge driving confidence. It’s crucial to regularly check these components. Ignoring signs of wear can have a tangible impact on both safety and costs.