Choosing the right components is crucial for any project. V Groove Ball Bearings stand out due to their unique design. These bearings provide smooth motion and adaptability in various applications.

V Groove Ball Bearings are perfect for linear movements. Their grooves allow for precise tracking. This makes them ideal for systems like conveyors and sliding doors. The right choice can enhance efficiency. However, not all projects require this type of bearing.

Users should consider specific needs. Are you working in a high-load environment? Or is precision your main concern? It's essential to reflect on these aspects. Although V Groove Ball Bearings have many benefits, they may not suit every application. Weighing the pros and cons is key to a successful project.

V Groove ball bearings are essential in mechanical applications for their unique design and functionality. They feature a groove-shaped outer race that allows for smooth movement along rails. This design reduces friction and wear, enhancing operational efficiency. Reports show that systems using V Groove bearings can experience up to 30% less friction, resulting in extended service life.

When selecting V Groove ball bearings, consider their load capacity. These bearings can handle both radial and axial loads effectively. This versatility makes them ideal for applications in conveyor systems, vertical lifts, and even automated machinery. Furthermore, their ability to maintain precision under varying loads can significantly improve production accuracy.

Tips: Always check compatibility with your existing systems. Sometimes, a mismatched bearing can lead to performance issues. Regular maintenance is crucial. Even the best bearings require periodic checks to prevent failures. Remember to observe operating temperatures as overheating can compromise performance and lifespan.

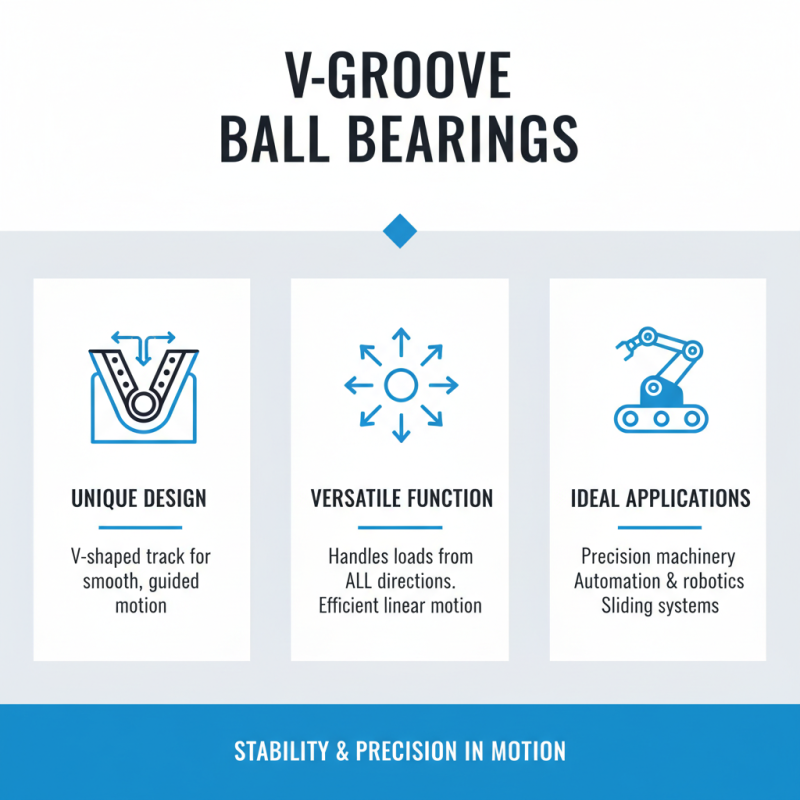

V groove ball bearings are designed with a unique groove shape that allows for smooth operation on various surfaces. This design feature enables the bearings to handle loads from different directions. The V-shaped groove acts as a track, guiding the ball for efficient linear motion. This makes them perfect for applications where precision and stability are paramount.

One challenge with V groove ball bearings is alignment. If not installed correctly, they can wear out quickly. Additionally, the material used in these bearings can affect performance. For instance, stainless steel may provide durability but can impact weight. It's vital to choose the right material depending on the application needs.

Maintenance is another critical aspect. Dust and debris can accumulate in the grooves, affecting performance. Regular cleaning helps to ensure the bearings operate efficiently. Users must consider the environment where the bearings will be used. Factors like humidity or temperature can influence their longevity.

When selecting V Groove ball bearings,

load capacity and speed ratings play crucial roles in performance.

Load capacity refers to the maximum weight the bearing can support.

Understanding this parameter helps ensure the longevity of your projects. Many designs require bearings that

can handle significant loads without failure. If the load exceeds the rating, premature wear occurs.

This can lead to costly repairs or complete system failure.

Speed ratings indicate how fast the bearing can rotate efficiently. A higher speed

rating means better performance in dynamic applications. However, pushing the limits can lead to

overheating and degradation. Finding the right balance is key.

Over-relying on speed without considering load can create problems.

It’s essential to assess both metrics during the selection process.

In practice, the environment where bearings operate also influences these metrics.

Factors like temperature,

humidity, and contamination can affect both

load capacity and speed. Real-world conditions often deviate from ideal scenarios.

Recognizing these variations is necessary for successful implementations.

Sometimes, simpler designs may outperform high-tech options in challenging

conditions. This calls for thoughtful evaluation and foresight during projects.

V groove ball bearings offer unique advantages for specific applications, especially when compared to standard bearings. These bearings feature a V-shaped groove that allows for smoother movement along guide rails or tracks. This design enhances stability and reduces friction, which can lead to increased efficiency in machinery. Standard bearings, while versatile, may not provide the same level of performance in these scenarios.

When it comes to load distribution, V groove bearings excel. They can handle radial and axial loads more effectively, making them suitable for applications that require precise alignment and support. However, their installation can be tricky. Improper alignment can lead to unexpected wear. Users must ensure correct mounting to reap the benefits.

On the downside, V groove bearings might not be suitable for all projects. They often come with a higher cost compared to standard options. This adds pressure on budgets. Developers must weigh the costs against the potential efficiency gains. While V groove bearings have significant advantages, they also demand careful consideration.

V groove ball bearings have garnered attention across various industries for their specialized applications. In material handling, these bearings facilitate smooth movement along tracks. They reduce friction, making machinery more efficient. For example, in conveyor systems, they ensure heavy loads move seamlessly. However, improper alignment can lead to increased wear and reduced performance.

In robotics, V groove ball bearings are pivotal in creating precise movements. Transferring forces effectively allows for more accurate operation. In applications like CNC machines, they provide stability. Yet, their design may require careful consideration regarding load limits. Overloading can jeopardize their lifespan.

The transportation sector also benefits from V groove ball bearings. They support wheels and guide systems, enhancing safety and reliability. In automated guided vehicles, these bearings play a crucial role. However, regular maintenance is essential for optimal functionality. Neglecting this can result in unexpected failures.

| Industry | Application | Benefits of V Groove Ball Bearings |

|---|---|---|

| Manufacturing | Conveyor systems | High precision and load-carrying capabilities |

| Automotive | Guidance systems | Reduced friction and enhanced performance |

| Aerospace | Control surface actuation | Reliability under extreme conditions |

| Agriculture | Farm equipment | Durable design for harsh environments |

| Robotics | Joint movement | Smooth operation and longevity |